A Practical Soft Capsule Drying Device

A technology of drying device and soft capsule, which is applied in the direction of drying gas arrangement, drying solid material, drying room/container, etc. It can solve problems such as difficult disassembly and cleaning, secondary pollution of capsules, and breeding of bacteria, and achieves convenient disassembly and cleaning , Improve drying efficiency and prevent feed blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

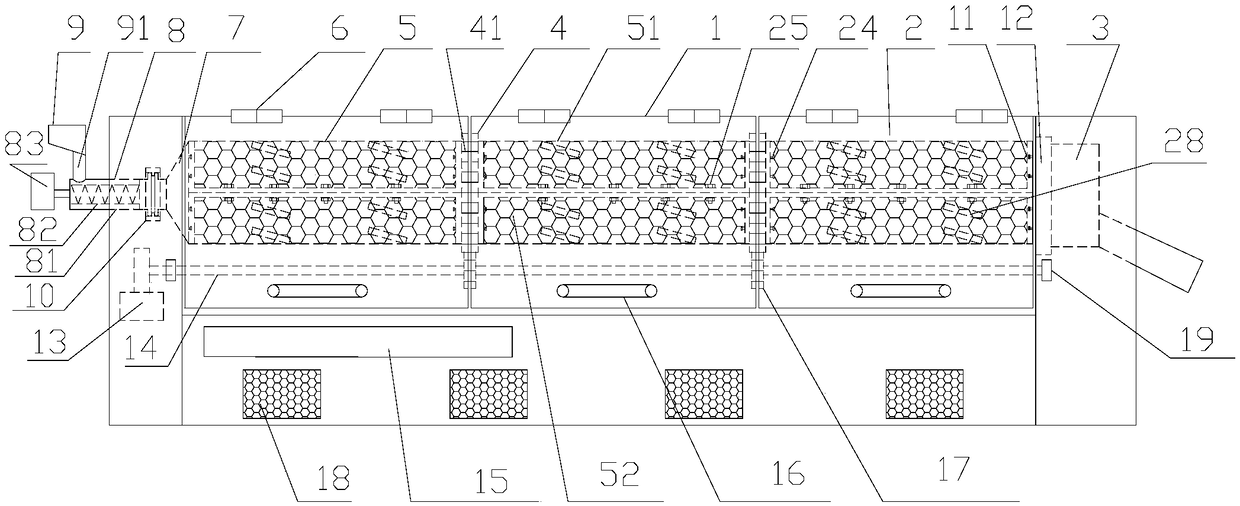

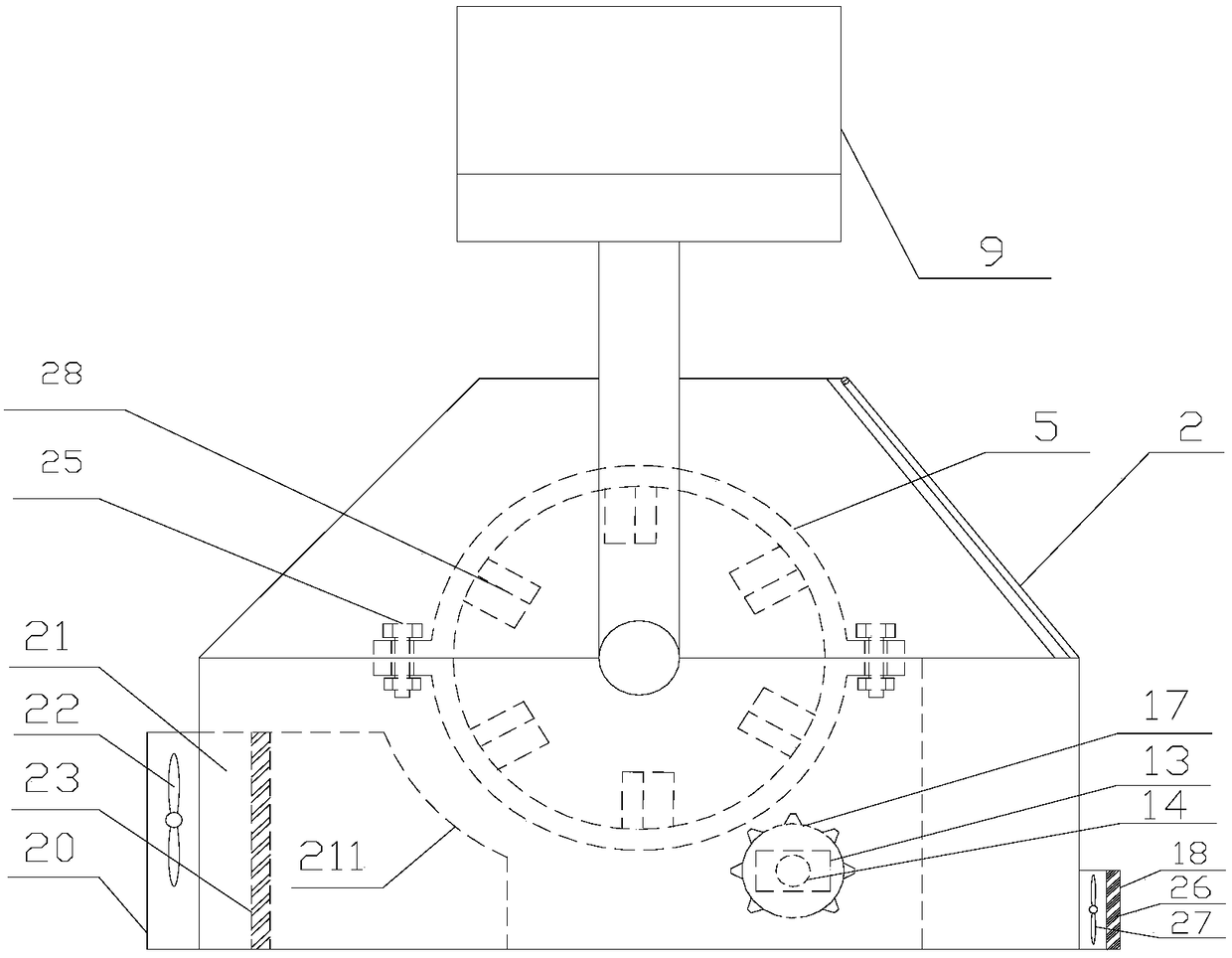

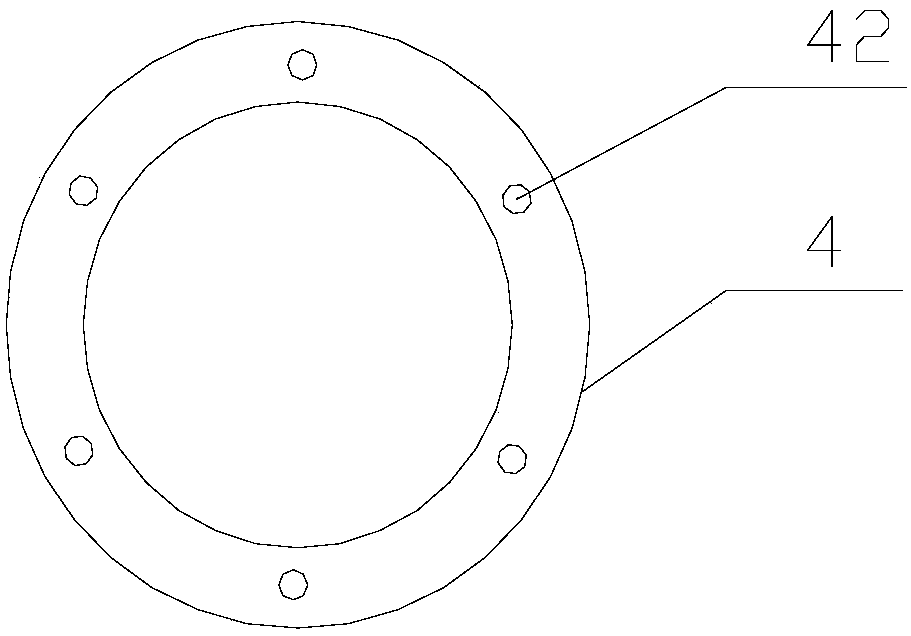

[0017] refer to Figure 1-4 , a practical soft capsule drying device of the present invention, comprising a cylinder body 1, an openable door 2, a discharge pipe 3, a drum connecting device 4, a drum 5, a hinge 6, a drum feeding port 7, and a feeding device 8. Hopper 9, bearing sleeve a10, drum discharge port 11, bearing sleeve b12, rotating shaft motor 13, rotating shaft 14, control device 15, handle 16, transmission gear 17, exhaust duct 18, rotating shaft bearing sleeve 19, drying auxiliary Device 20, docking fixing screws 24, connecting bolts 25, negative pressure fan 26, screen window 27 and material guide plate 28, the openable warehouse door 2 is installed on the cylinder body 1 through the hinge 6, and the drum 5 is fixed by docking The screw 24 is fixed on the drum connection device 4, and the drum 5 is also connected to the drum feed port 7 and the drum discharge port 11 respectively through the docking fixing screws 24, and the drum 5 is respectively connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com