Different diameter and groove clamp

A technology of different diameters and wire clamps, applied in the direction of cable suspension devices, etc., can solve the problems of safety production hazards, broken strands, burnt out, etc., and achieve the effects of reducing operating time, improving production efficiency, and ensuring clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

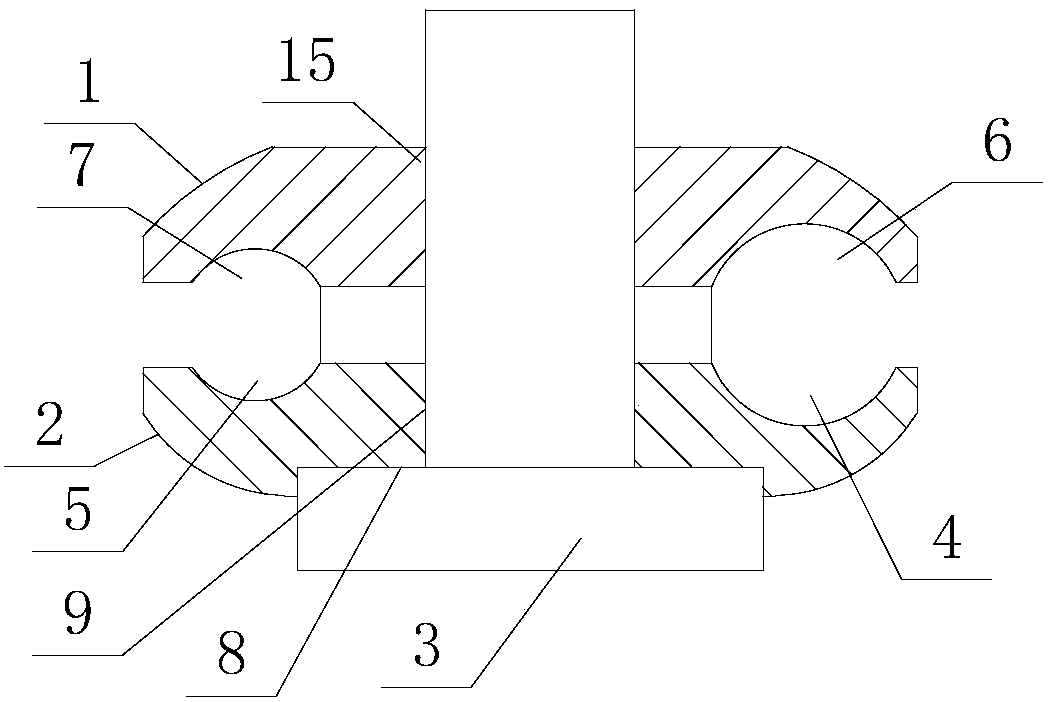

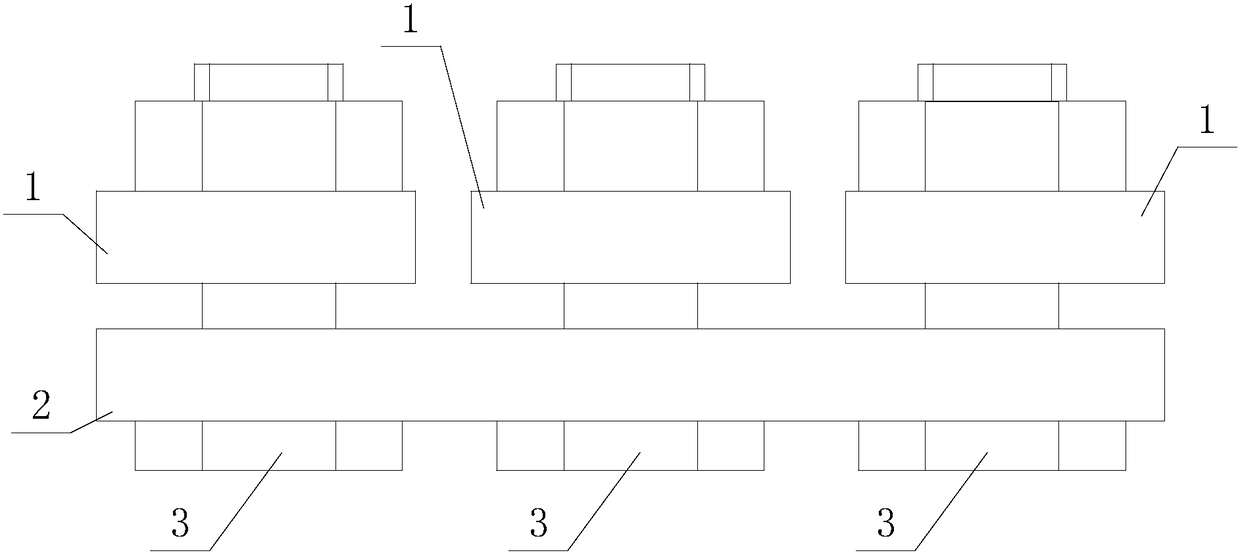

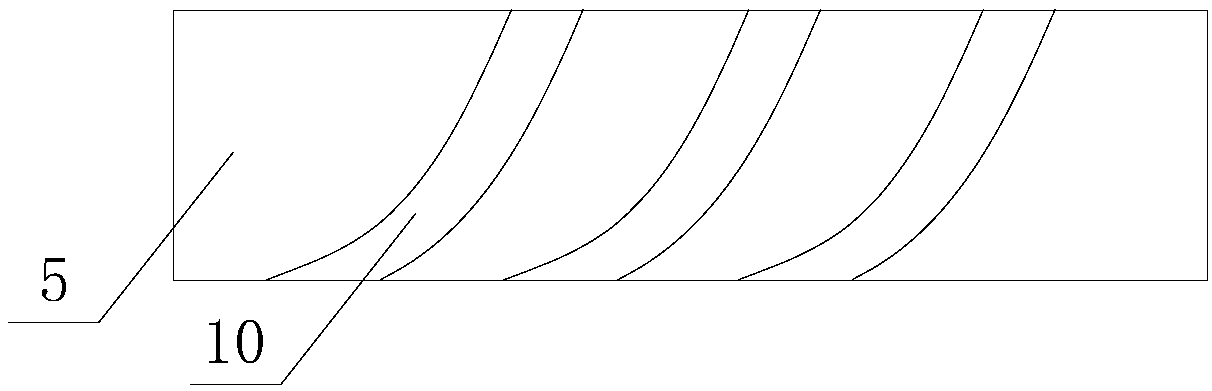

[0018] see figure 1 , figure 2 It is an embodiment of the different diameter parallel groove wire clamp of the present invention. The different diameter parallel groove wire clamp comprises an upper clamping base 1, a lower clamping base 2 and a fastening bolt 3, and at least one upper clamping base 1 is provided on the lower clamping base 2, The upper surface of the lower clamping seat 2 is provided with a lower large-diameter groove 4 and a lower small-diameter groove 5 along the length direction. Setting, the lower large-diameter groove 4 and the lower small-diameter groove 5 are located in parallel on the left and right sides of the horizontal centerline of the lower clamping base 2; the bottom surface of the upper clamping base 1 is provided with an upper large-diameter groove 6 and an upper small-diameter groove 7 along the length direction, The upper large-diameter groove 6 is located directly above the lower large-diameter groove 4, and the upper small-diameter groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com