Lifting sling

A spreader and hook technology, applied in the field of lifting, can solve problems such as difficult installation, decoupling, no spreader, etc., and achieve the effects of increased service life, convenient installation and disassembly, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

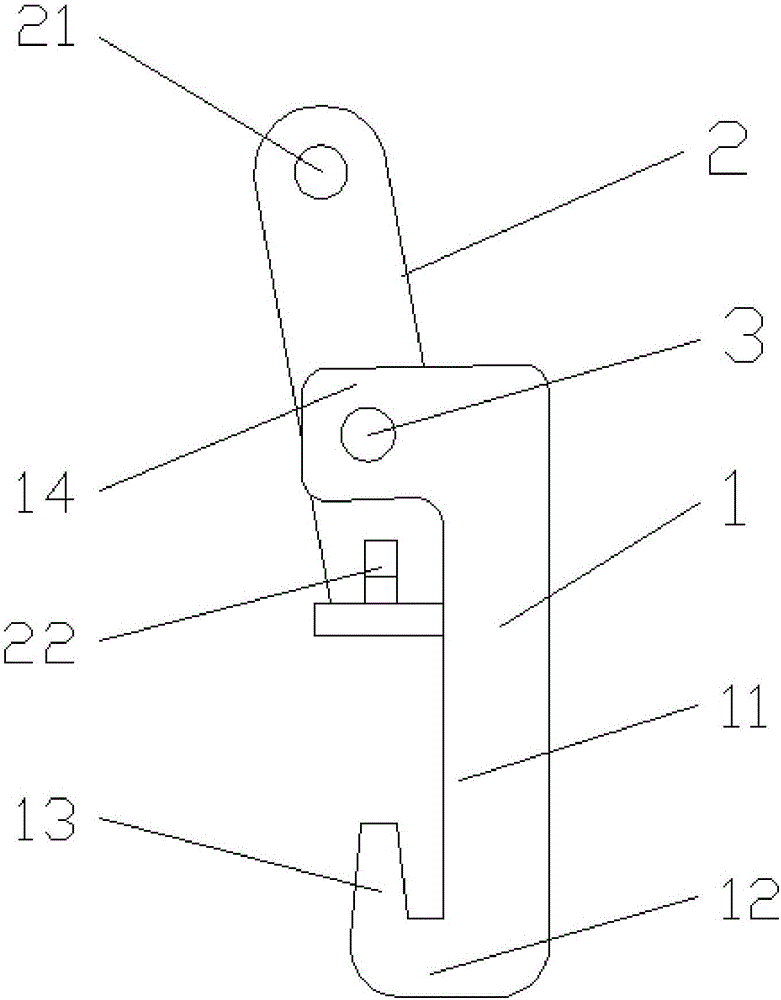

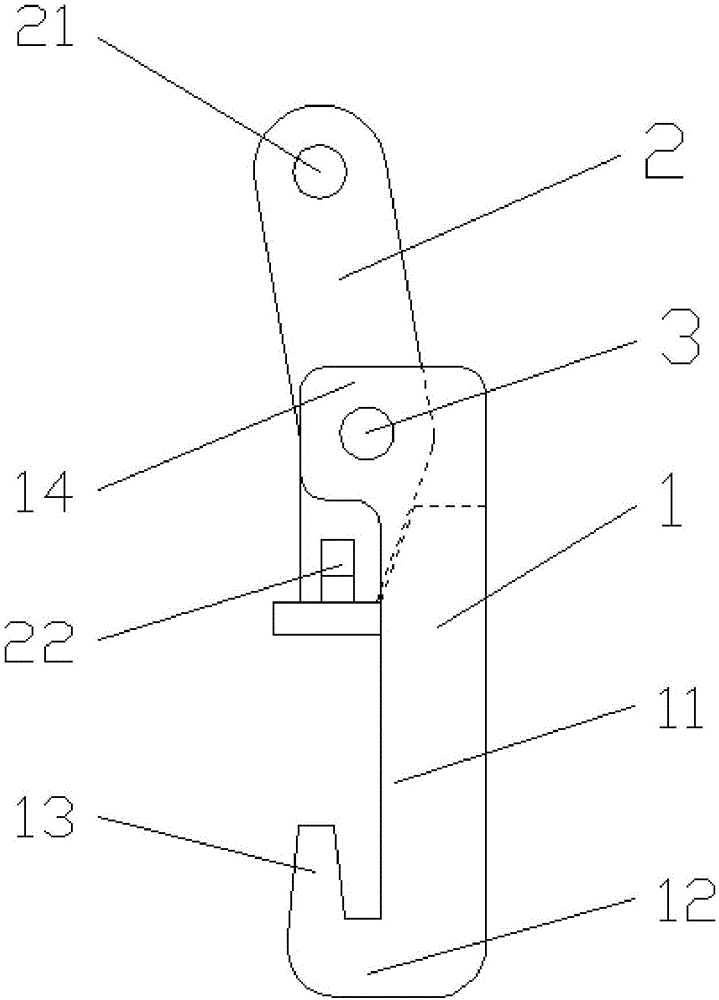

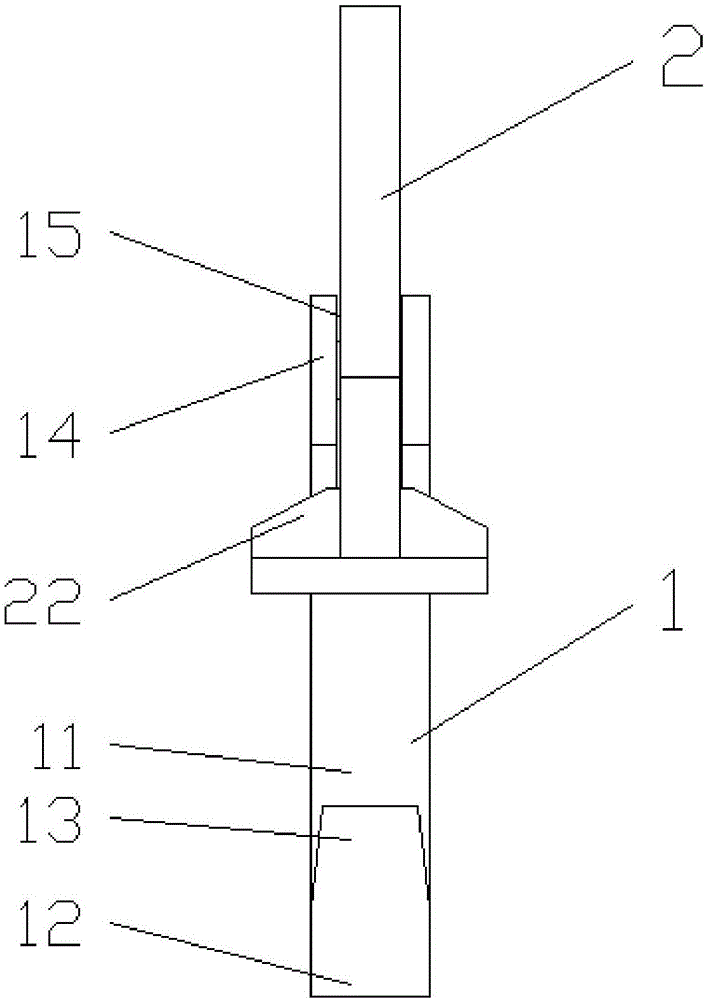

[0030] Such as figure 1 As shown, a suspension includes a hook 1 and a fixing member 2. The hook 1 includes a straight arm 11, a cross arm 12, and a hook portion 13. The bottom end of the straight arm 11 is connected to one end of the cross arm 12, and the cross arm 12 The other end of the straight arm 11 is connected to the hook 13, and the top of the straight arm 11 is provided with a transverse lug 14, the lug 14 faces the side of the hook 13, and the top surface of the straight arm 11 has a through groove 15, and the through groove 15 runs through the lug 14 The fixed part 2 passes through the through groove 15, the fixed part 2 is connected with the lug 14 by the pin shaft 3, the width of the bottom part of the fixed part 2 is greater than the width of the through groove 15, and the upper part of the fixed part 2 is provided with a hoisting hole 21, and the fixed part 2 The bottom is provided with reinforcing ribs 22, and the bottom surface of the fixing part 2 is a plane...

Embodiment 2

[0032] On the basis of Embodiment 1, the fixing part 2 is a bar-shaped plate, and the central axis of the upper part of the fixing part 2 and the central axis of the lower part of the fixing part 2 form an angle of 10°.

[0033] Installation method of the present invention (the same as embodiment one and embodiment two):

[0034] Such as Figure 4 As shown, rotate the fixing part 2 to turn the lower part of the fixing part 2 to the level, then use the hook part 13 of the hook 1 to hook the lower eaves on the side of the material rack 4, and then reversely rotate the fixing part 2 to make the bottom of the fixing part 2 The lower part is close to the inner wall of the straight arm 11, the lower surface of the fixing part 2 just touches the upper surface of the material rack 4, and then is connected with the hanging chain through the hoisting hole 21. Due to the gravity of the hanging chain itself, the hanging chain will swing to the material rack 4 center, so the hanging chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com