Preparation method of compressive pre-stress artificial rock core

A technology of artificial core and pre-stress, which is applied in the preparation of test samples, sampling, measuring devices, etc., can solve the problems of not having to manufacture cores of different sizes, stress storage instructions, etc., and achieve simple operation, simple materials, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

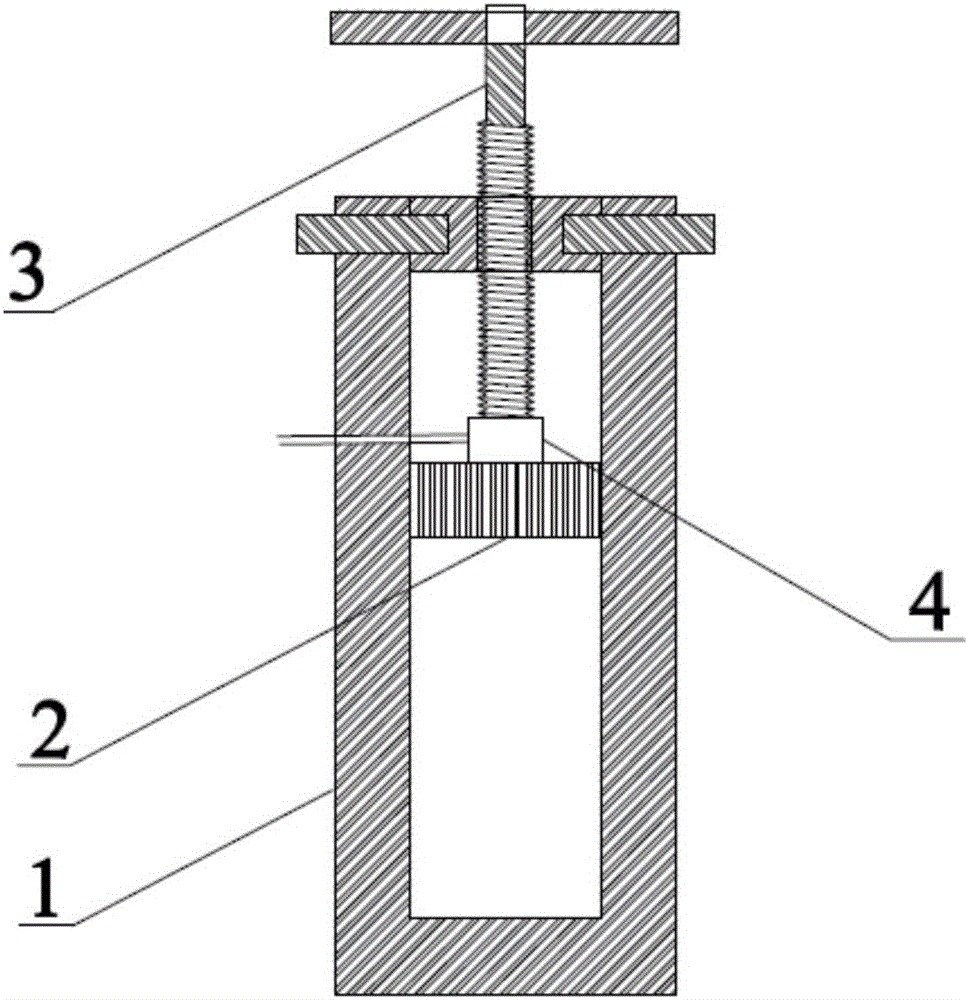

[0031] A method for preparing a precompressed artificial rock core, comprising the steps of:

[0032] (1) Mix and stir the epoxy resin A component and the curing agent B component;

[0033] (2) After adding quartz sand to the mixture in step (1), stir evenly;

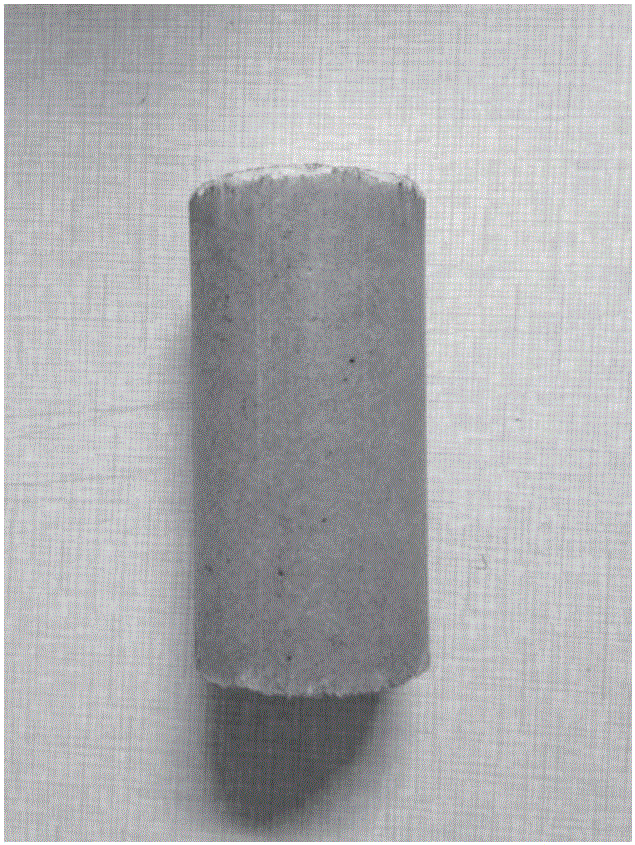

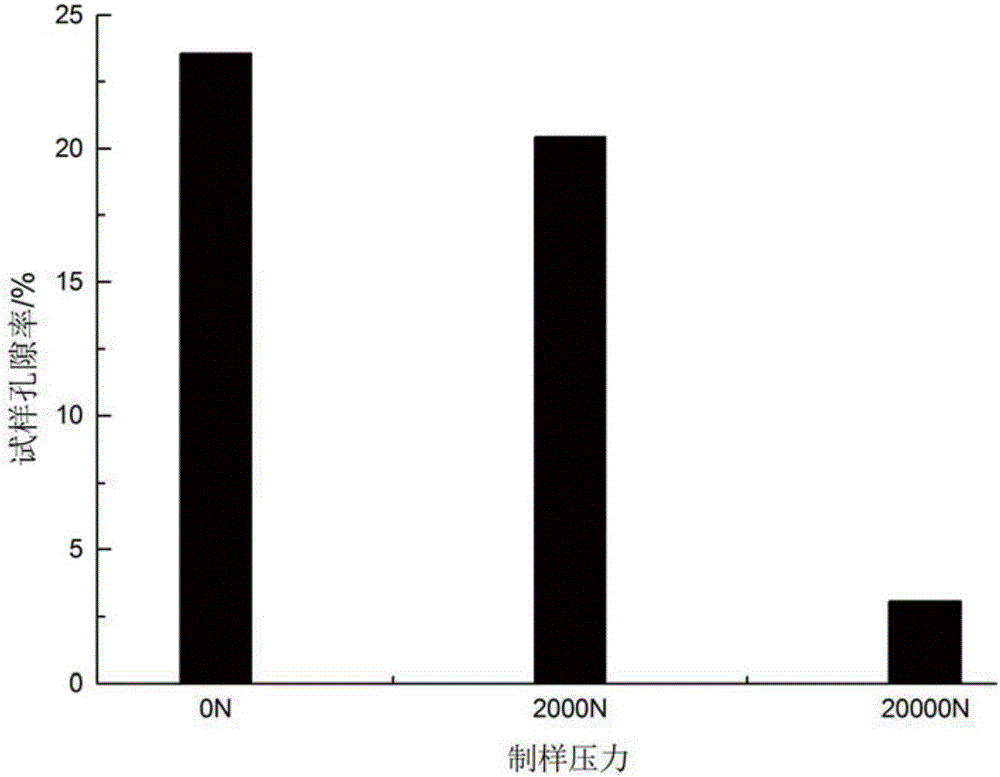

[0034] (3) Layer-cast the mixture in step (2) into an internal stress cylindrical mold, coat a layer of release agent between the mold and the mixture, apply pressure to the mixture in (2) through the screw handle, and wait for the cylindrical sample After curing and molding, the internal stress core can be obtained.

[0035] In this embodiment, the mass ratio of the epoxy resin component A to the curing agent B component is 3:1.

[0036] In this embodiment, the mass ratio of the mixture of the epoxy resin component A and the curing agent B component to the quartz sand is 1:1.

[0037] In this embodiment, the particle size of the quartz sand is 18 mesh.

[0038] In this embodiment, the model of the epoxy resin is HZ...

Embodiment 2

[0047] A method for preparing a precompressed artificial rock core, comprising the steps of:

[0048] (1) Mix and stir the epoxy resin A component and the curing agent B component;

[0049] (2) After adding quartz sand to the mixture in step (1), stir evenly;

[0050] (3) Layer-cast the mixture in step (2) into an internal stress cylindrical mold, coat a layer of release agent between the mold and the mixture, apply pressure to the mixture in (2) through the screw handle, and wait for the cylindrical sample After curing and molding, the internal stress core can be obtained.

[0051] In this embodiment, the mass ratio of the epoxy resin component A to the curing agent B component is 3:1.

[0052] In this embodiment, the mass ratio of the mixture of the epoxy resin component A and the curing agent B component to the quartz sand is 1:1.

[0053] In this embodiment, the particle size of the quartz sand is 80 mesh.

[0054] In this embodiment, the model of the epoxy resin is HZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com