Silicon carbide complex, method for manufacturing same, and heat dissipation component using same

A composite and silicon carbide technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, electric solid-state devices, etc. The effect of the close coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~4

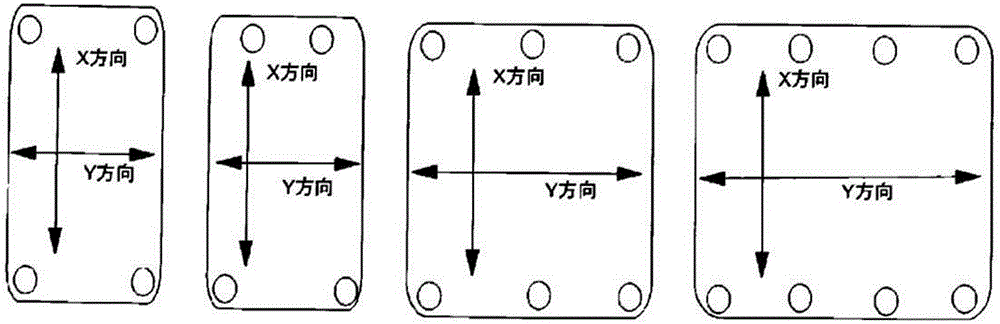

[0062] Silicon carbide powder A (produced by Pacific Randon Co., Ltd.: NG-150, average particle diameter: 100 μm), silicon carbide powder B (produced by Yakushima Denko Co., Ltd.: GC-1000F, average particle diameter: 10 μm), and silica sol ( Nissan Chemical Co., Ltd. production: SNOWTEX) was compounded with a mass ratio of 60:40:10, mixed with a stirring mixer for 1 hour, and formed into a shape of 187mm×137mm×7mm under a pressure of 10MPa. Thereafter, the molded body was heated at 960° C. for 2 hours in the air to produce a silicon carbide porous body. The obtained silicon carbide porous body is processed into The relative density is calculated according to the size and mass, and the result is 65%.

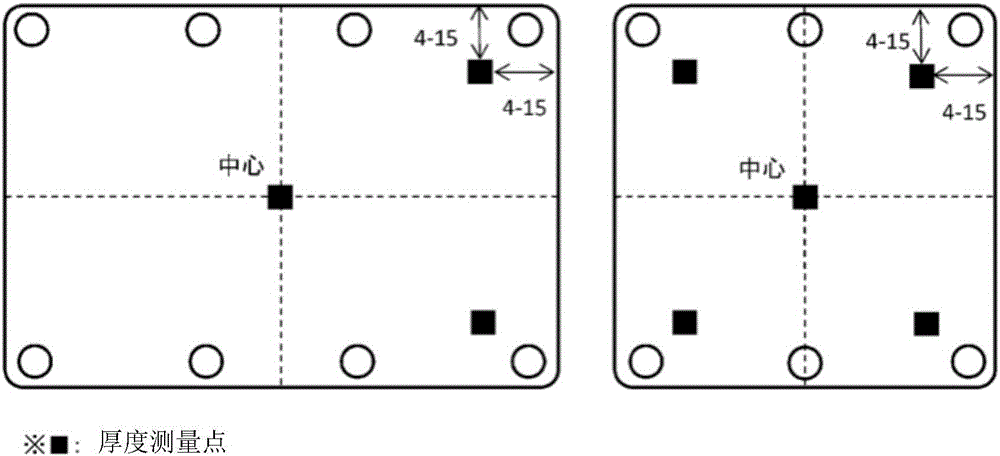

[0063] Next, the obtained silicon carbide porous body was processed to a desired thickness with a diamond processing tool, and 12 samples of each sample were separated by a 0.8 mm thick SUS plate coated with a release agent, and the After configuring iron plates with a thickne...

Embodiment 9~11

[0079] The silicon carbide composite body manufactured in Comparative Example 1 was mounted on image 3 In the shown jig made of SUS-304, the stress perpendicular to the main surface was loaded with M10 screws, heated in an electric furnace at a temperature of 500°C for 30 minutes, and then cooled to room temperature to release the load. Table 5 shows the amount of warpage of the composite obtained. Next, Table 5 shows the results of evaluating the obtained composites by the same method as in Examples 1 to 8. As shown in Table 5, the adhesion rate can be improved by forming the convex surface using a jig.

[0080] [table 5]

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com