Method of synthesizing sec-butyl acetate and apparatus therefor

A technology of sec-butyl acetate and acetic acid, which is applied in the field of synthesizing sec-butyl acetate and its equipment, can solve the problems of catalyst deactivation, temperature rise control failure, complex reactor structure, etc., and achieve high selectivity, heat reduction, protection The effect of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0093] Example 1:

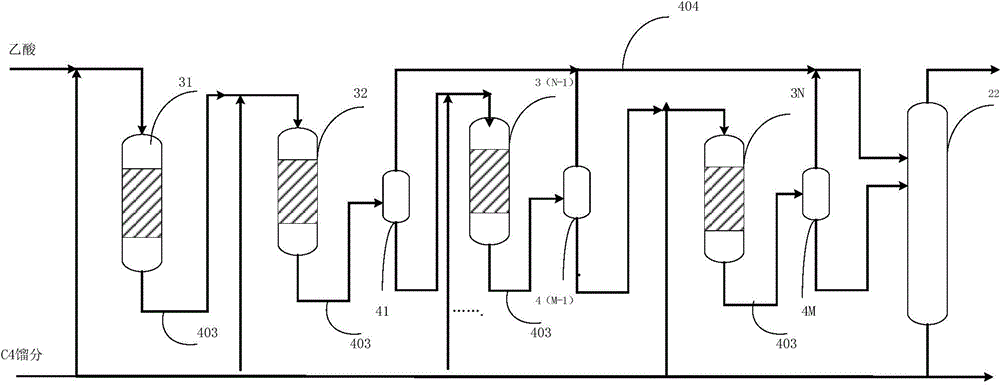

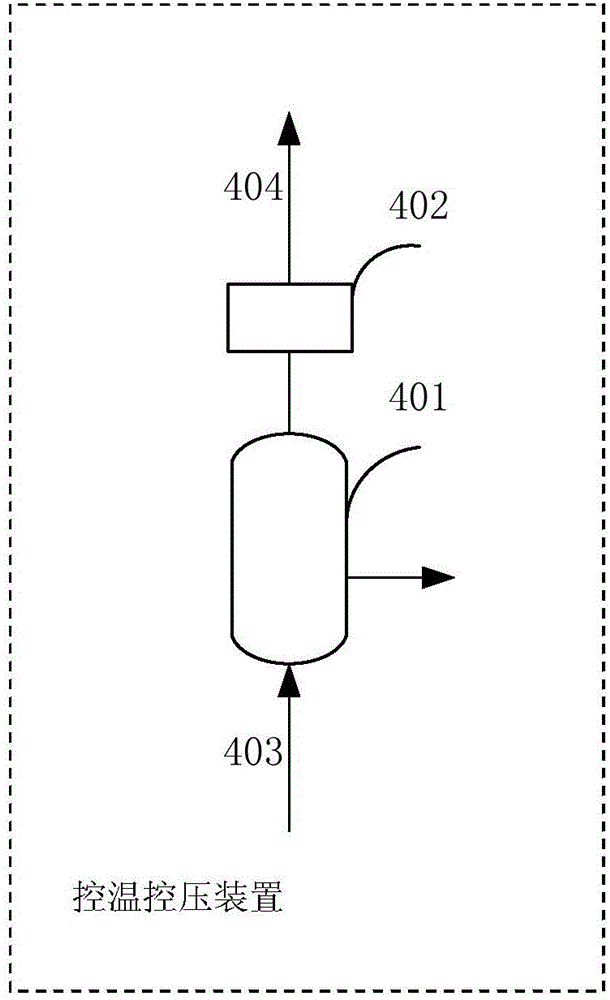

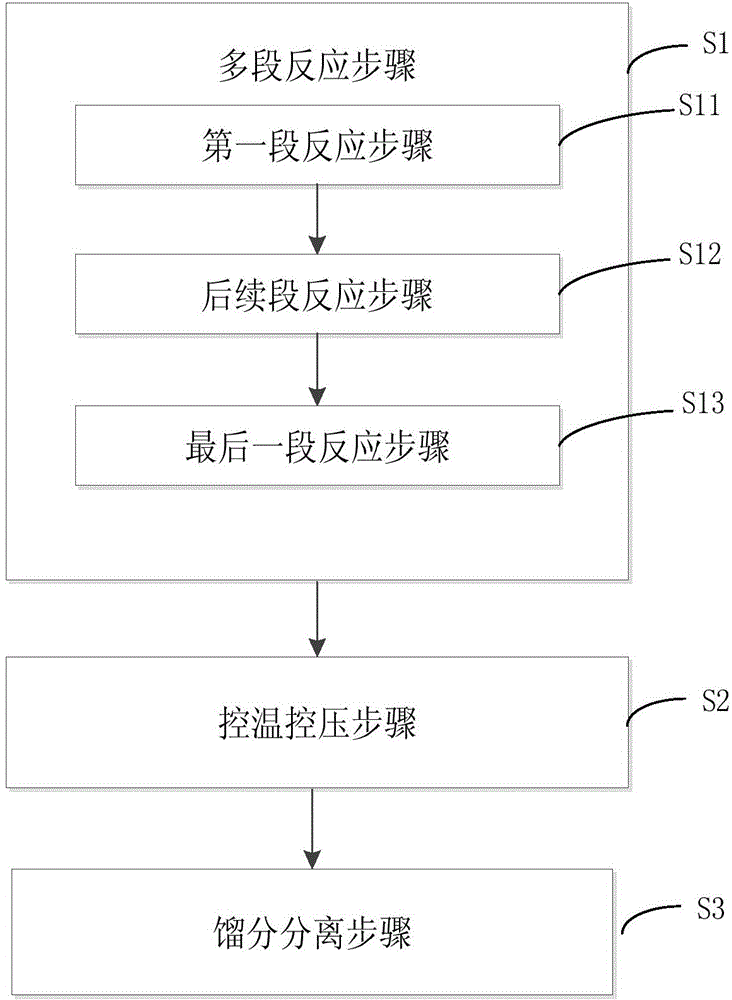

[0094] according to Figure 4 In the process shown, the composition (mass percentage) of C4 fraction 1 is: 41.6% of isobutane, 13.3% of n-butane, 17.3% of 1-butene, 0.2% of isobutene, 13.5% of butene, and 15.1% of butene. The total butene is 45.1%.

[0095] The flow rate of C4 fraction 1 is 1000kg / h, the temperature is 20℃, and the pressure is 2.6MPa. The 200kg / h of C4 fraction 2 of the first stage is mixed with 1208kg / h of acetic acid 5 and then enters the first stage adiabatic fixed bed reactor 7. The inlet temperature is 60.0℃, the reaction pressure is 2.0MPa, and the C4 fraction feed mass space velocity is 4.0h -1 , The adiabatic temperature rise of the reactor is 36.6℃; the product 8 is mixed with 300kg / h of the second stage C4 fraction 3 and then enters the second stage adiabatic fixed bed reactor 10, the reactor inlet temperature is 72.6℃, the reaction pressure is 0.5MPa, C4 Distillate feed mass space velocity 2.0h -1 , The adiabatic temperature rise is...

Example Embodiment

[0099] Example 2:

[0100] according to Figure 4 In the process shown, the composition (mass percentage) of C4 fraction 1 is: isobutane 53.1%, n-butane 11.3%, 1-butene 14.6%, isobutene 2.1%, maleic 8.9%, butene 10.0%, The total butene is 35.6%.

[0101] The flow rate of C4 fraction 1 is 1000kg / h, the temperature is 20℃, and the pressure is 2.6MPa. The first stage C4 fraction 200kg / h is mixed with 1524kg / h of acetic acid 5 and then enters the first stage adiabatic fixed bed reactor 7. The reactor inlet temperature 50.0℃, reaction pressure 2.5MPa, C4 fraction feed mass space velocity 3.0h -1 , The adiabatic temperature rise is 24.1℃; the product 8 is mixed with 400kg / h of the second stage C4 fraction and enters the second stage adiabatic fixed bed reactor 10, the reactor inlet temperature is 62.9℃, the reaction pressure is 0.5MPa, and the C4 fraction feed quality Airspeed 2.0h -1 , The adiabatic temperature rise is 31.0℃; after being separated by the vapor-liquid separation tank 1...

Example Embodiment

[0105] Example 3:

[0106] according to Figure 4 In the process shown, the composition (mass percentage) of C4 fraction 1 is: isobutane 53.1%, n-butane 11.3%, 1-butene 14.6%, isobutene 2.1%, maleic 8.9%, butene 10.0%, The total butene is 35.6%.

[0107] The flow rate of C4 fraction 1 is 1000kg / h, the temperature is 20℃, and the pressure is 2.6MPa. The 200kg / h C4 fraction of the first stage is mixed with 1208kg / h of acetic acid 5 and then enters the first stage adiabatic fixed bed reactor 7. The reactor inlet temperature It is 60.0℃, reaction pressure is 2.0MPa, C4 fraction feed mass space velocity is 4.0h -1 , The adiabatic temperature rise is 28.3℃; the product 8 is mixed with 300kg / h of the second stage C4 fraction and then enters the second stage adiabatic fixed bed reactor 10. The reactor inlet temperature is 68.0℃, the reaction pressure is 0.5MPa, and the C4 fraction feed quality Airspeed 1.5h -1 , The adiabatic temperature rise is 27.1℃; after being separated by the vapor-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap