Movable air cooling device for decreasing temperature of heavy gauge strip steel

A thick gauge, cooling device technology, applied in workpiece cooling device, temperature control, workpiece surface treatment equipment, etc., can solve the problems of white rust defects on the surface of strip steel, inability to form passivation film, large strip thickness, etc. Degradation and waste generation, good effect, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

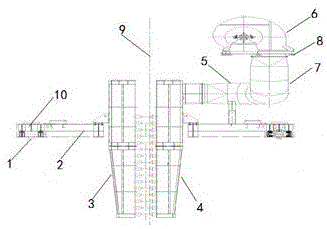

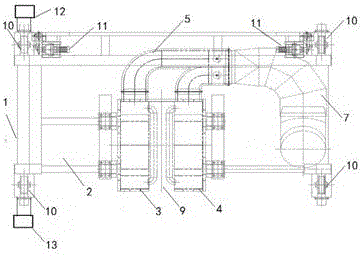

[0017] figure 1 with figure 2 It is shown that a mobile cooling device for reducing the temperature of thick strip steel of the present invention includes a guide rail 1, a mobile platform 2, a wheel 10 installed on the lower part of the mobile platform 2 and walking along the guide rail 1, a motor 11 that drives the wheel 10 to rotate, and is fixed to the mobile 1#wind box 3 and 2#wind box 4 on platform 2, air-cooled pipe 5 with one end hermetically connected to 1#wind box 3 and 2#wind box 4, air-cooled fan 6, and fan pipe 7 hermetically connected with air-cooled fan 6 at one end , The transmission side position detection device 12 and the operation side position detection device 13 respectively installed on the guide rail 1 and located on the transmission side and the operation side of the mobile platform 2. The transmission side position detection device 12 and the operation side position detection device 13 can be stoppers , Used to detect the moving position of the mobile...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap