Polyoxamide powder and preparation method thereof

A technology of polyoxamide and powder, which is applied in the field of polyoxamide powder and its preparation, can solve problems affecting popularization and application, consume large solvent, and high cost, and achieve good application prospects, uniform particle size distribution, and regular shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

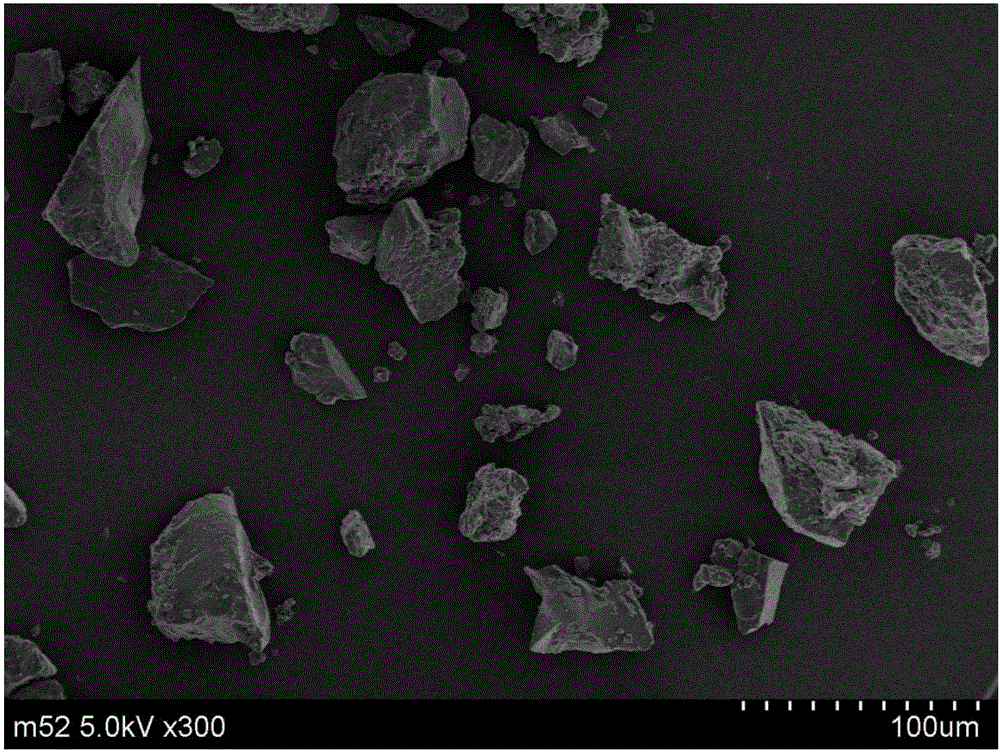

[0035] Dibutyl oxalate monomer (202.25g) and decane diamine monomer (177.49g) were pumped into the nozzle through the dosing pump at 3m. 3 Atomization polymerization is carried out in a nitrogen gas stream at a temperature of 22.15 min. The N102 prepolymer is obtained by vacuum drying. The N102 prepolymer is pulverized by a pulverizer to obtain prepolymer powder. The aforementioned prepolymer powder At 3m 3 The solid-phase polymerization is carried out in a nitrogen gas stream at a temperature of 150℃, the solid-phase polymerization time is 3h, and the vacuum degree of the solid-phase polymerization is 200Mpa to obtain N102 polymer powder. Use a pulverizer to remove N102 polymer powder. It was further pulverized to obtain N102 powder with an average particle size of 180.5 μm and a melting point of 250°C measured by DSC.

Embodiment 2

[0037] Dibutyl oxalate monomer (202.25g) and decane diamine monomer (177.49g) were pumped into the nozzle through the dosing pump at 4m 3 Atomization polymerization is carried out in a nitrogen gas stream at a temperature of 22.15 min. The N102 prepolymer is obtained by vacuum drying. The N102 prepolymer is pulverized by a pulverizer to obtain prepolymer powder. The aforementioned prepolymer powder At 4m 3 / h for solid-phase polymerization in a nitrogen gas stream. The solid-phase polymerization temperature is 170℃, the solid-phase polymerization time is 5h, and the solid-phase polymerization vacuum is 220Mpa to obtain N102 polymer powder. Further pulverize to obtain N102 powder. Put 100g of the aforementioned N102 powder and 0.5g of white carbon black into a high-speed mixer and mix until the mixture is evenly mixed to obtain N102 / silica mixture powder. The average particle size is 140.2μm. The melting point measured by DSC is 250.1°C.

Embodiment 3

[0039] Dibutyl oxalate monomer (202.25g) and decane diamine monomer (177.49g) were pumped into the nozzle through the dosing pump at 5m 3 Atomization polymerization is carried out in a nitrogen gas stream at a temperature of 22.15 min. The N102 prepolymer is obtained by vacuum drying. The N102 prepolymer is pulverized by a pulverizer to obtain prepolymer powder. The aforementioned prepolymer powder At 5m 3 / h for solid-phase polymerization in a nitrogen gas stream. The solid-phase polymerization temperature is 180℃, the solid-phase polymerization time is 8h, and the solid-phase polymerization vacuum is 250Mpa to obtain N102 polymer powder. Further pulverize to obtain N102 powder. Put 100g of the aforementioned N102 powder and 1g of white carbon black into a high-speed mixer and mix until they are evenly mixed to obtain N102 / silica mixture powder. The average particle size is 100.1μm, and the melting point measured by DSC is 250.4. ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com