Turbine housing and associated exhaust turbocharger

A technology for exhaust turbines and turbines, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., and can solve problems such as failure of exhaust turbochargers, and achieve the effects of reducing costs, reducing weight, and reducing material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

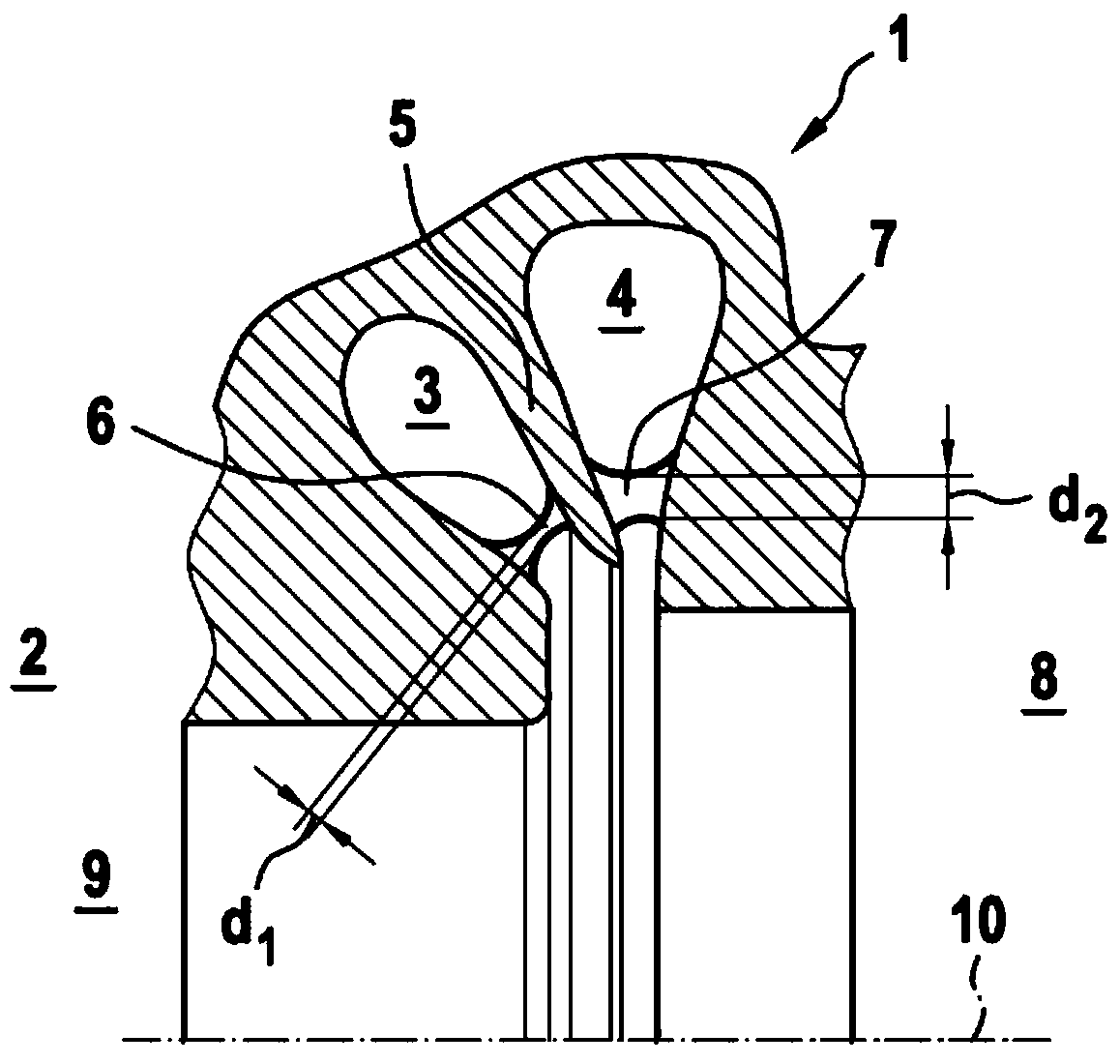

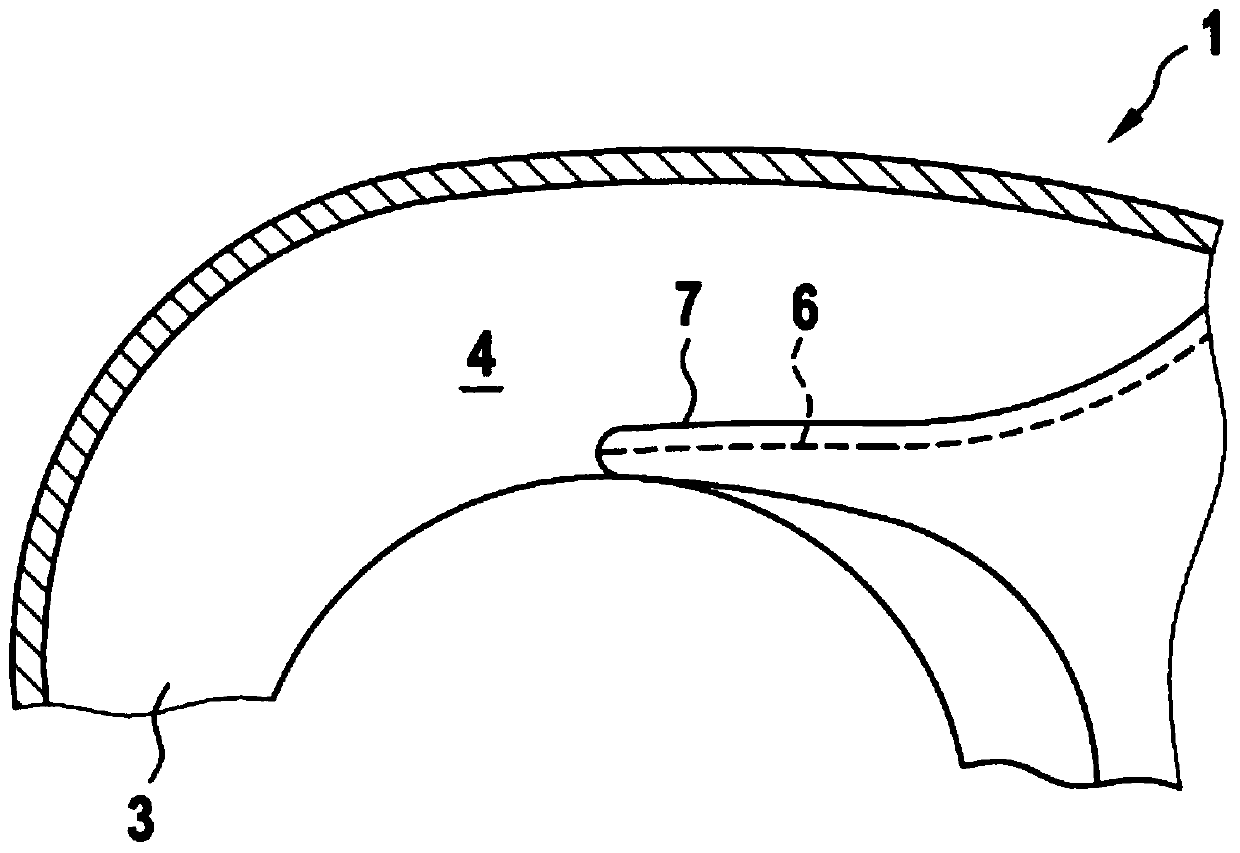

[0016] corresponds to figure 1 and figure 2 , the turbine housing 1 according to the invention has an exhaust turbocharger 2 (or not shown) and has two helical exhaust channels 3, 4 through which The partitions 5 are separated from each other and are delimited radially to the outside by the turbine housing 1 and in each case by a screw tongue 6 , 7 to the inside. In this case, in the direction of the turbine housing 1 the two screw tongues 6 , 7 extend in opposite directions away from the web 5 . here, figure 1 Only the upper half of the turbine housing 1 is shown, wherein the exhaust channel 4 is arranged adjacent to the bearing housing 8 and the exhaust channel 3 is arranged adjacent to the exhaust pipe 9 . In this case, during operation of the exhaust-gas turbocharger 2 , in particular the second screw tongue 7 is exposed to high thermal loads and is therefore at risk of cracks forming, wherein, in the event of a crack forming in the second screw tongue 7 , The crack p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com