A high-power LED integrated light source packaging method

A packaging method and high-power technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of insufficient brightness of a single light source, and achieve the effect of simple and convenient production process, solving insufficient brightness, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

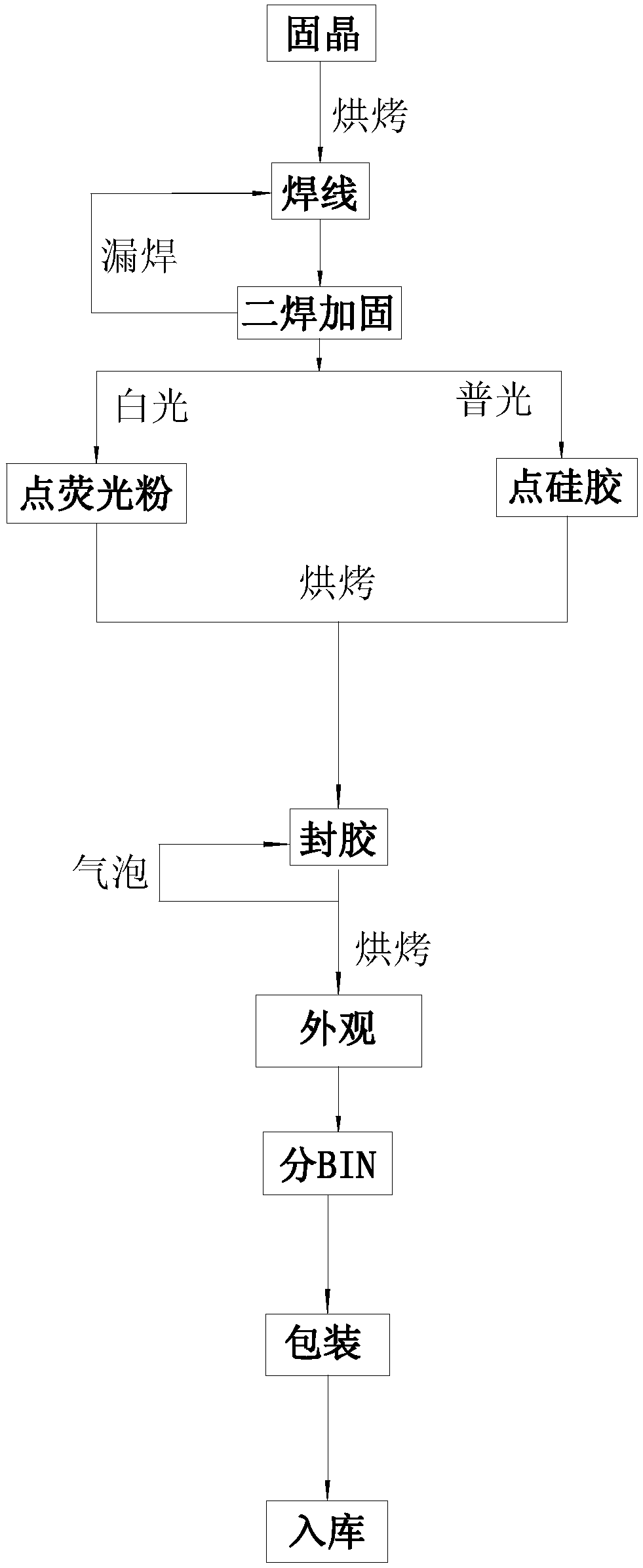

[0019] Referring to the accompanying drawings, a high-power LED integrated light source packaging method includes the following steps: (1) Die bonding: put the bracket into the high-power die-bonding fixture in the same direction; remove the silver plastic seat of the machine, and thaw it Put the silver glue into the silver glue seat; install the solid crystal silver glue seat, connect the air pipe; turn on the power and display switch, connect the air source; operate the machine, adjust the silver glue seat to the rotating state; according to the specific size of the chip put into production, Replace with matching thimble, suction nozzle and dispensing head, the specific model is provided by the equipment; remove the die-bonding arm, loosen the chip seat buckle, put the expanded chip into the chip seat and fix it; put the installed bracket on the Enter the material inlet, and put the empty fixture into the material outlet for use; adjust the relative direction of the chip and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com