Rectification tower plate for improving heat transferring and mass transferring performance and rectification tower

A technology of heat and mass transfer and rectification tower, which is applied in the direction of fractionation, etc., can solve the problems that the diameter and strength of the I-beam cannot meet the requirements, the distance of the liquid travels greatly, and the area of a single tray is large, so as to save The effect of downcomer and liquid receiving area, reducing flow dead area, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

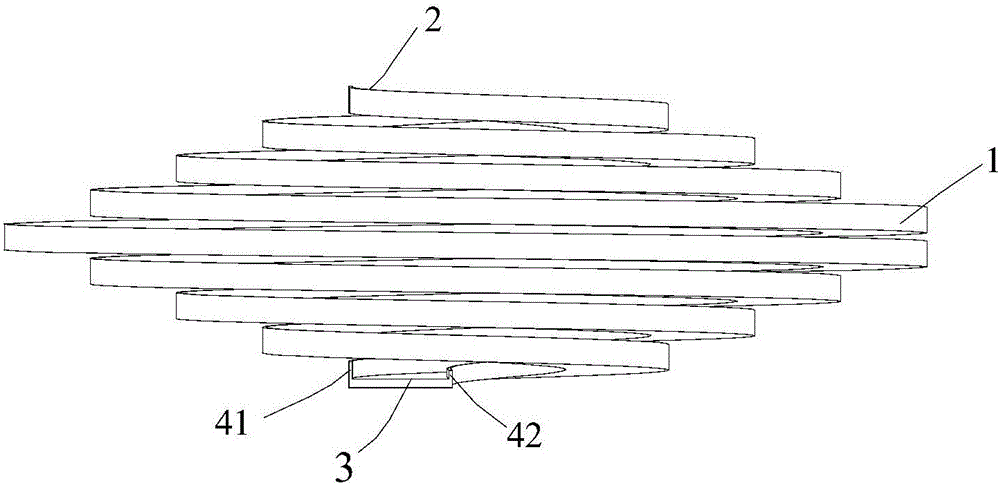

[0034] A rectification tower for improving heat and mass transfer performance, with a tower height of 10 meters and a tower diameter of 2 meters, including 40 rectification tower trays, and all rectification tower trays are arranged along the same vertical line. Such as figure 1 As shown, the rectification column tray includes a tray body 1, the tray body 1 is a spiral structure, the top is provided with a liquid inlet 2, and the bottom is provided with a liquid outlet 3, and the upper rectification column tray The liquid outlet is connected with the liquid inlet of the next rectification column tray.

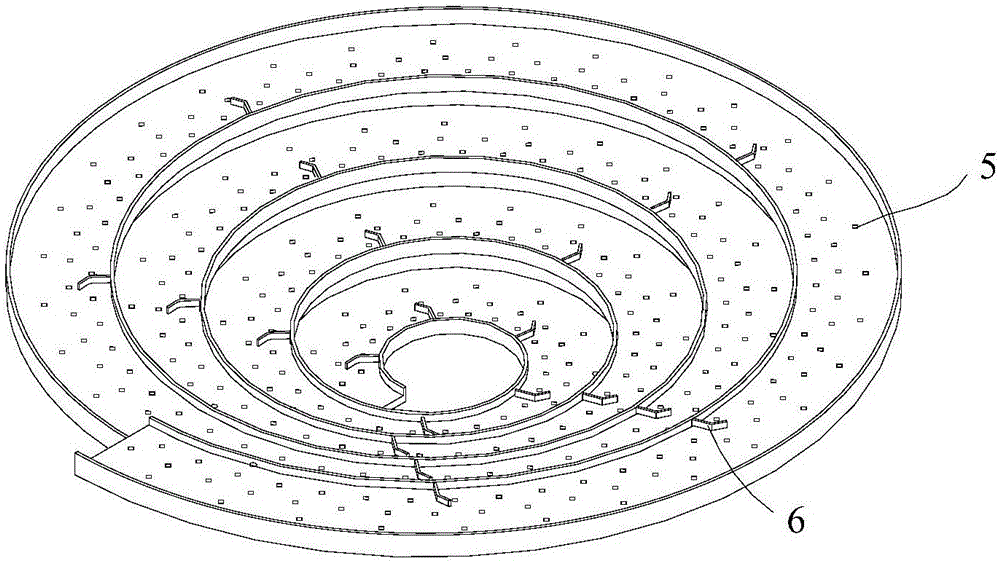

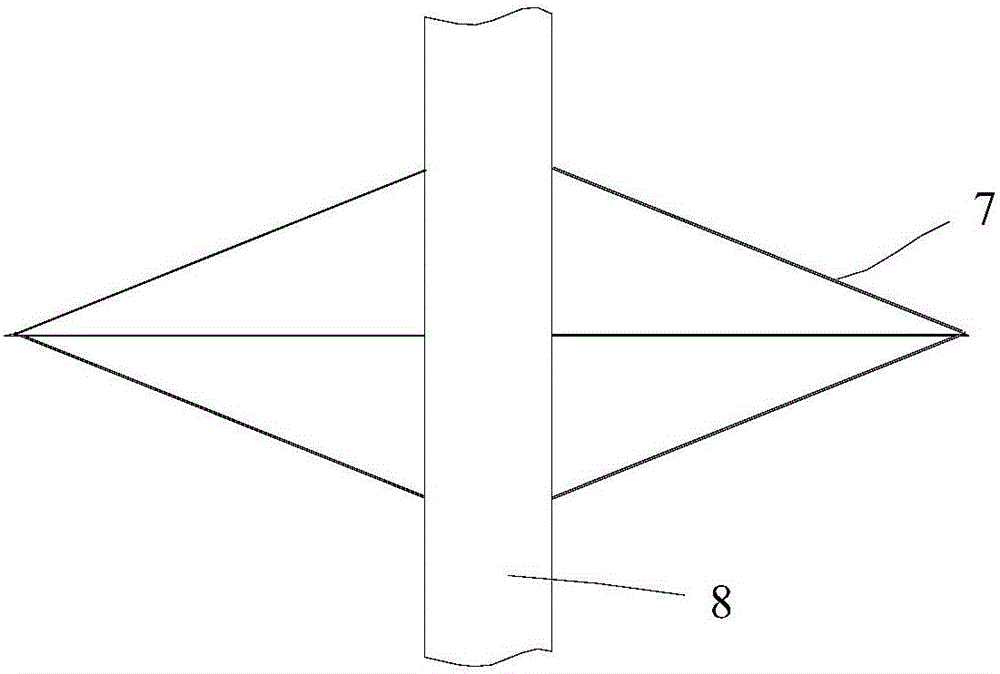

[0035] The helical diameter of the helical structure gradually decreases from the middle to both ends, presenting a top shape in three-dimensional space. Each tray unit is composed of 8 spirals, the diameter of which increases gradually along the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com