Method for heating and upsetting of end of steel bar

A processing method and steel bar technology, which is applied in the field of steel bar end heating and upsetting processing, can solve the problems affecting the forming quality of the upsetting head, bending of the steel bar end, high heating temperature, etc., and achieve convenient installation and construction, high anchoring rigidity and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] The present invention relates to a heating and upsetting processing method for the end of a steel bar, in which one end of the steel bar is heated and then upset to form an enlarged upsetting head, and the enlarged and upsetting steel bar at the end is mainly used as a mechanical anchoring method for a reinforced concrete structure. Including the following processing steps:

[0029] 1. Rebar heating:

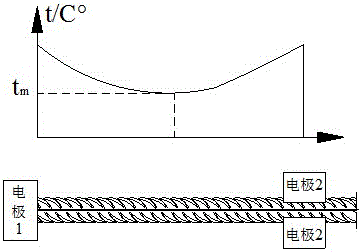

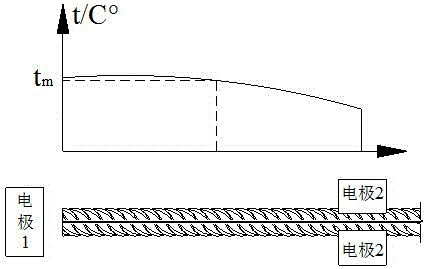

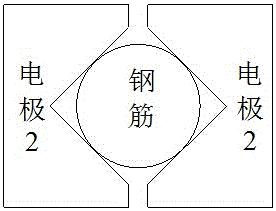

[0030] According to the process requirements, one end (end area) of the steel bar is heated, usually by means of resistance heating; a first heating electrode 1 is set at the end of the steel bar, and a second heating electrode 2 is set at a certain distance away from the end; And apply force to the first heating electrode 1 and the second heating electrode 2 respectively, so that the plane of the first heating electrode 1 is close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com