Two-component adhesive and preparation method thereof

A two-component adhesive and curing agent technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of strong fluidity, easy aging, poor thixotropy, etc., and achieve good environmental performance, Environmentally friendly and easy to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

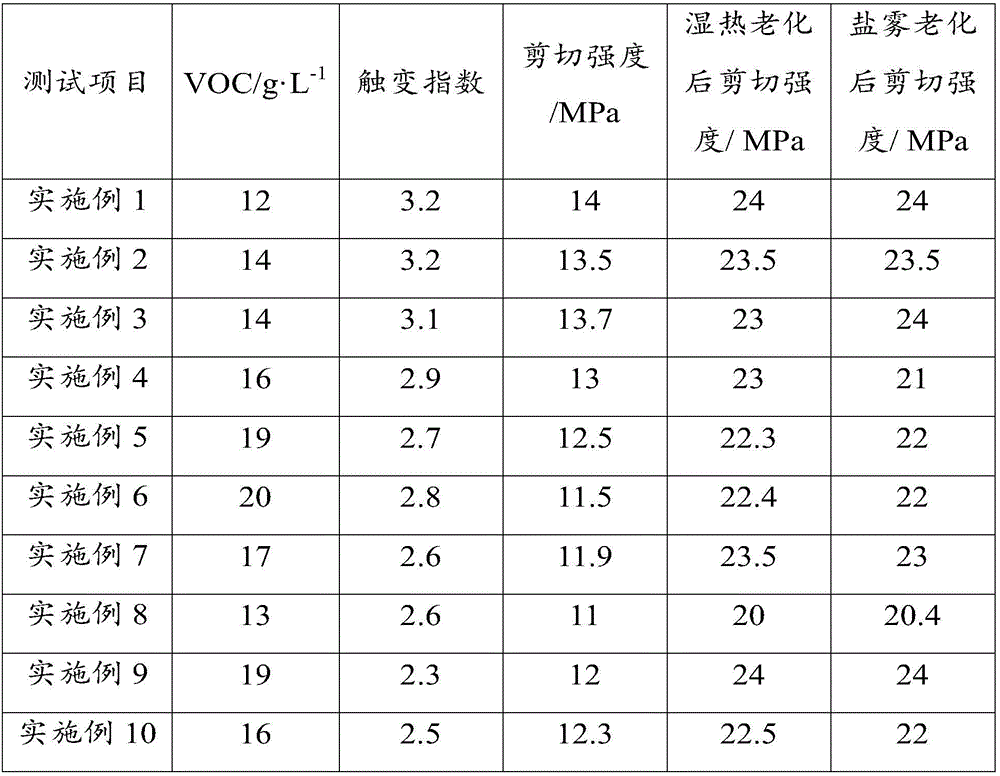

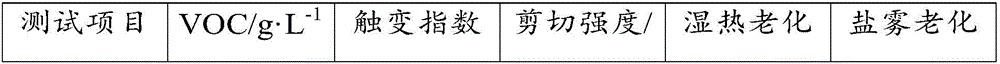

Examples

Example Embodiment

[0052] The preparation method of the following two-component adhesive includes the following steps:

[0053] S1. Weigh the raw materials according to the formula of the following examples 1-8;

[0054] S2. Stir the epoxy resin and reactive diluent evenly, then add nano calcium carbonate and powder fillers, and stir into a uniform paste. The stirring speed is 60 rpm, the time is 1 h, and the stirring temperature is 20 ℃. Obtain the A component;

[0055] S3. Stir the modified amine curing agent and dispersant evenly, then add nano calcium carbonate and powder filler, and stir into a uniform paste. The stirring speed is 60 rpm, the time is 1 hour, and the stirring temperature is 20°C. , And then get the B component;

[0056] S4. Mix the well-stirred component A and component B and stir for 45s to obtain a two-component adhesive.

Example Embodiment

[0057] Example 1

[0058] A two-component adhesive, mainly composed of A component and B component. The A component includes the following parts by mass: 100% bisphenol A epoxy resin 29 parts, nano-calcium carbonate 10 parts, 2.5 parts of benzyl glycidyl ether, 25 parts of quartz powder and 30 parts of calcium carbonate powder;

[0059] The B component includes the following parts by mass of raw materials: 29 parts of modified polyether ammonia, 10 parts of nano calcium carbonate, 2.5 parts of dispersant for epoxy adhesive (D310, Guangzhou Suibo Trading Co., Ltd.), 25 parts of quartz powder and 30 parts of calcium carbonate powder;

[0060] The A component and the B component are compounded and used at a mass ratio of 2:1.

Example Embodiment

[0061] Example 2

[0062] A two-component adhesive, mainly composed of component A and component B, component A includes the following parts by mass of raw materials: 28 parts of bisphenol A epoxy resin, 8 parts of nano calcium carbonate, and C12 alkyl glycidol 2 parts of ether, 25 parts of asbestos powder and 25 parts of mica powder;

[0063] The B component includes the following parts by mass of raw materials: 14 parts of modified polyether ammonia, 14 parts of modified isophorone diamine, 8 parts of nano calcium carbonate, dispersant for epoxy adhesive (D310, Guangzhou Suibo Trading Limited company) 2 parts, 25 parts of asbestos powder and 25 parts of mica powder;

[0064] The A component and the B component are compounded and used at a mass ratio of 2:1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap