A yarn dyeing device

A technology of yarn dyeing and dyeing cylinder, which is applied in the direction of processing textile material equipment configuration, spraying/jetting textile material processing, etc. The effect of dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

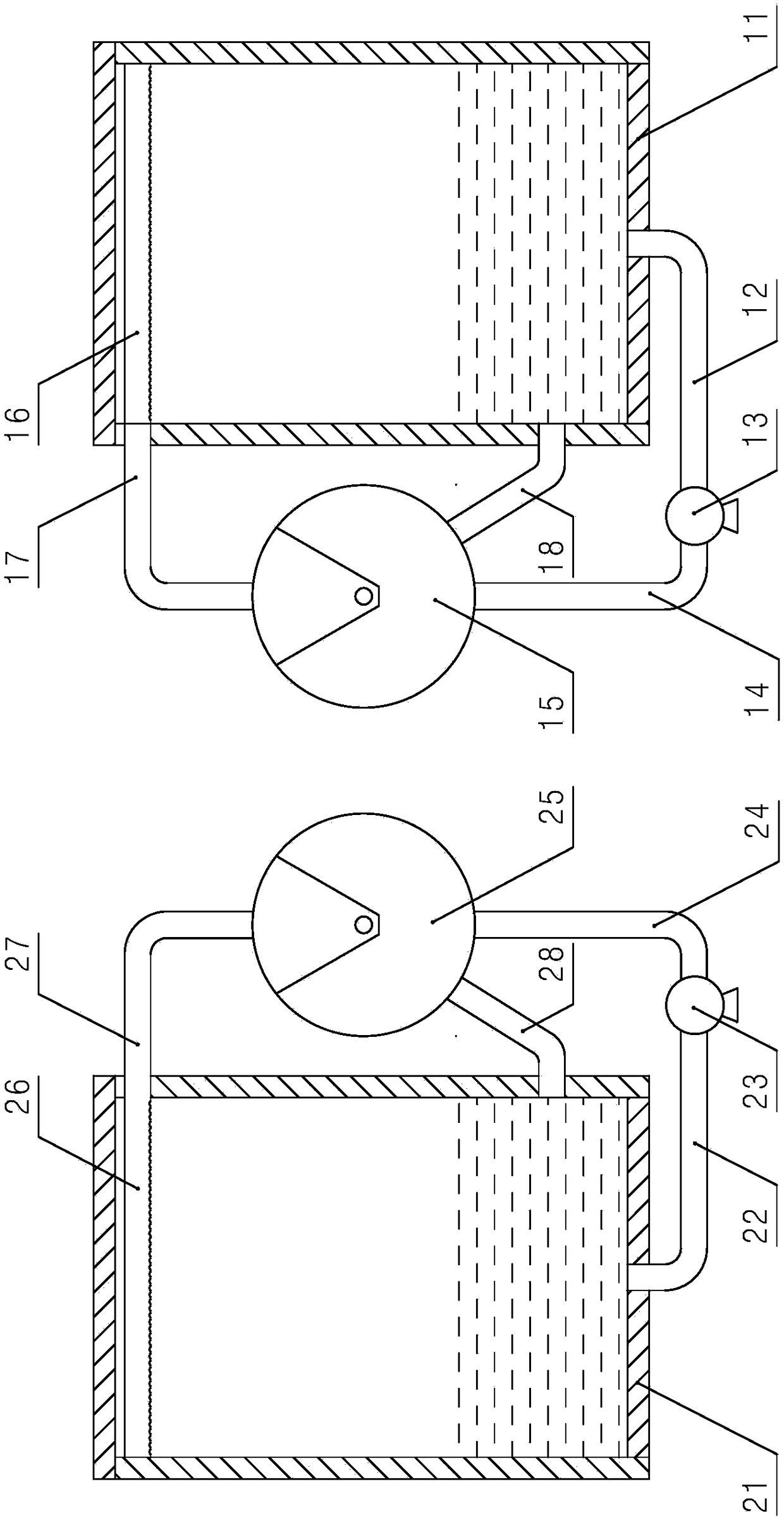

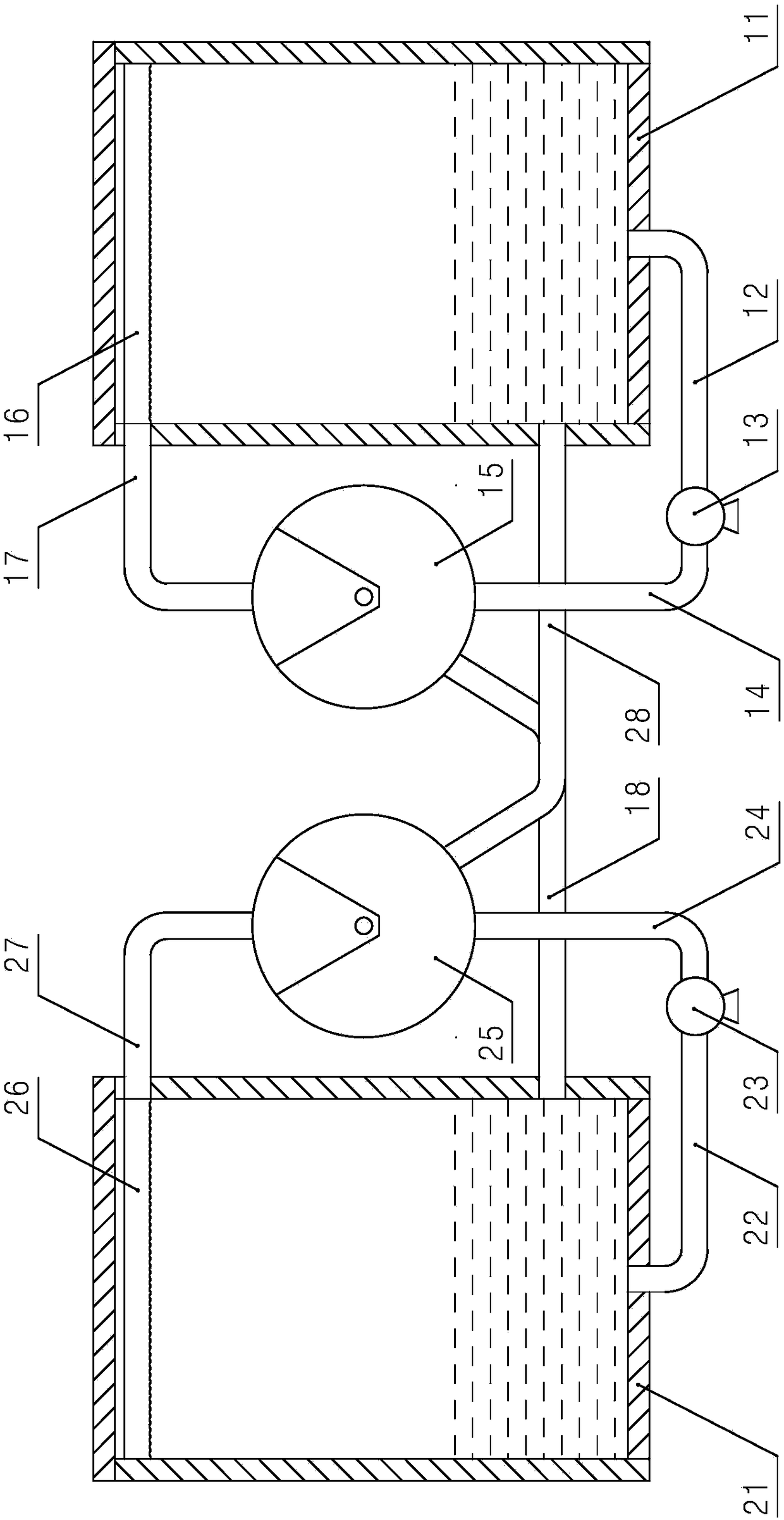

[0013] Attached below figure 2 , to describe in detail the specific implementation of a yarn dyeing device of the present invention.

[0014] Such as figure 2 As shown, the yarn dyeing device of the present invention includes: the first dyeing vat 11, the second dyeing vat 21, the first circulating pump 13 and the first angle control valve 15 for the first dyeing vat 11, and for The second circulating pump 23 and the second angle control valve 25 that the second dyeing vat 21 is matched with, the top of the first dyeing vat 11 inner chamber is provided with the first spray pipe 16, and the top of the second dyeing vat 21 inner chamber is provided with the first spray pipe 16. Two spray pipes 26, the first circulating pump 13 communicates with the liquid outlet provided at the bottom of the first dyeing vat 11 through the first liquid inlet pipe 12, and communicates with the first angle control valve through the first liquid outlet pipe 14 The liquid inlet of 15 is communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com