An automatic spray paint production line

An automatic spraying and production line technology, applied in spray booths, spraying devices, pretreated surfaces, etc., can solve the problems of large floor space, large baking heat loss, low thermal efficiency, etc., to save land, excellent appearance quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

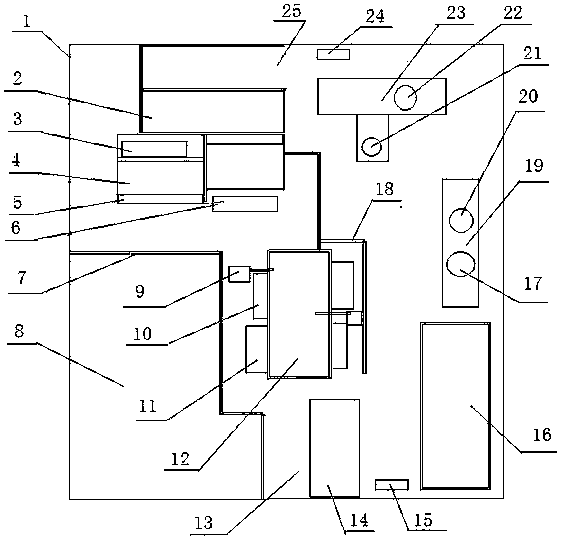

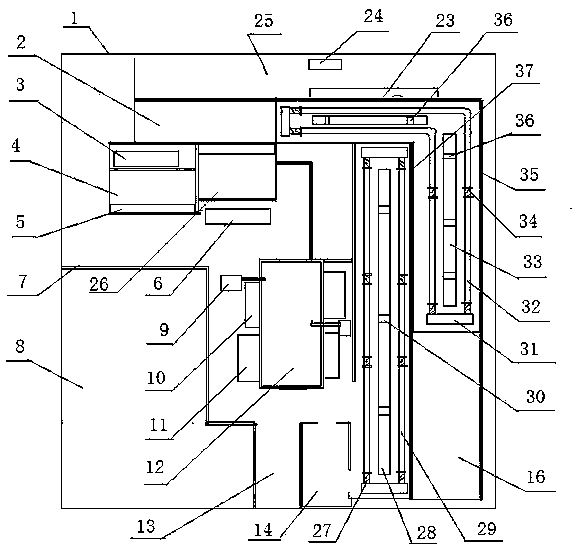

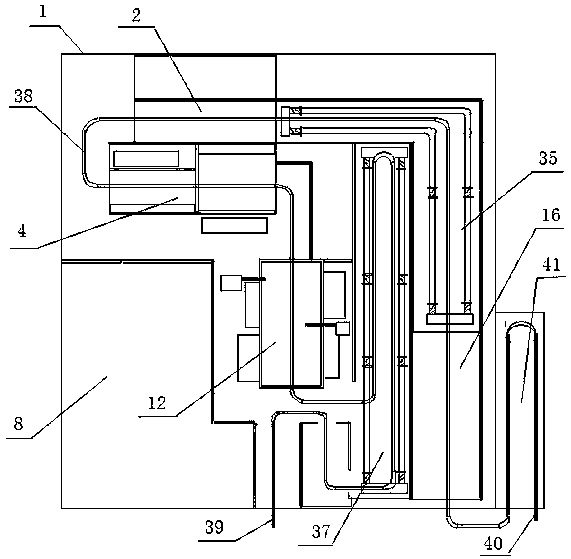

[0015] In the figure, an automatic spraying and baking paint production line includes a dust-free compartment 1, a heating furnace, a suspension conveyor rail 38, baking equipment, painting equipment, coating equipment, and dust removal equipment. Two floors, the dust-free compartment 1 includes a lifting tunnel 16, a drying tunnel 35, a descending tunnel 2, a water curtain spraying room 4, an electrostatic powder spraying room 12, and a baking tunnel 37 connected in sequence; the drying tunnel 35 is located on the second floor. The entrance of the drying tunnel 35 is connected with the lifting tunnel 16, and the lifting tunnel 16 is connected with the pretreatment; the exit of the drying tunnel 35 leads to the descending tunnel 2, and the exit of the descending tunnel 2 is closely connected to the water curtain spraying room 4 on the lower floor, and the exit of the electrostatic powder spraying room 12 is connected to the The entrance of the baking tunnel 37, the exit of the ...

Embodiment 2

[0017] On the basis of Embodiment 1, the drying tunnel 35 and the baking tunnel 37 do not have an interlayer, and a return air duct is arranged on the top of the drying tunnel 35 and the baking tunnel 37, and the return air outlet 44 is opened on the return air duct. Connect the air induction pipe, the air induction pipe will use the superheated air to cause dehumidification, and then send it back to the heating furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com