Organic light emitting diode display device and manufacturing method of panel

A technology for light-emitting diodes and display panels, which is applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of display device damage, easy mixing of water vapor, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

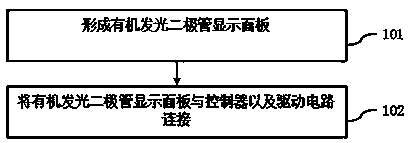

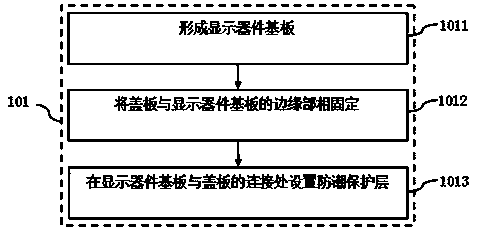

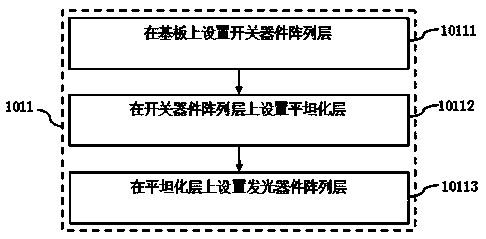

[0022] refer to figure 1 , figure 2 and image 3 , figure 1 It is a flow chart of the manufacturing method of the organic light emitting diode display device of the present invention, figure 2 for figure 1 A flowchart of the steps of forming an organic light emitting diode display panel in , image 3 for figure 2 A flowchart of the steps of forming a display device substrate in .

[0023] The manufacturing method of the organic light emitting diode display device of the present invention comprises the following steps:

[0024] A (step 101 ), forming an organic light emitting diode display panel.

[0025] B (step 102), connecting the organic light emitting diode display panel with the controller and the driving circuit.

[0026] Wherein, the step A includes:

[0027] a1 (step 1011 ), forming a display device substrate.

[0028] a2 (step 1012 ), fixing the cover plate to the edge of the display device substrate, wherein the cover plate covers at least a part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com