Coffee-color translucent packaging paper and processing process thereof

A processing technology, translucent technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of color difference, fading, and weak sense of color layering of brown translucent wrapping paper, etc., to achieve improved coloring rate, vivid colors, rich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

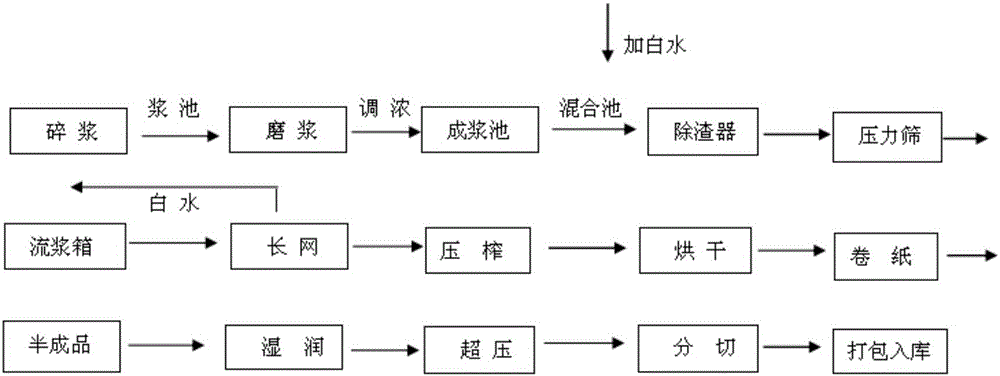

[0019] Such as figure 1 As shown, a brown translucent wrapping paper is made of raw materials and pigments, the raw materials are composed of 50% coniferous leaves and 50% broadleaf by mass, and the pigments are composed of materials of the following mass: Straight press dark brown 20 kg / ton dry pulp, direct press acid-resistant bright red 2.5 kg / ton dry pulp, direct press fast black 1.8 kg / ton dry pulp, direct press indigo 0.03 kg / ton dry pulp, rose essence 0.01 kg / ton dry pulp Dry pulp, acid orange 1.2 kg / ton dry pulp, chemical fixing agent 2 kg / ton dry pulp and salt 4 kg / ton dry pulp.

[0020] A processing technology of brown translucent wrapping paper, comprising the following steps:

[0021] 1) The raw materials are subjected to pulping treatment, and then enter into the pulp tank;

[0022] 2) After adding the pigment, carry out grinding treatment, then carry out thickening and enter into the slurry forming tank;

[0023] 3) The slurry in the slurry tank flows into the...

Embodiment 2

[0028] Such as figure 1 As shown, a coffee-colored translucent wrapping paper is made of raw materials and pigments, the raw materials are composed of 50% coniferous leaves and 50% broadleaf by mass, and the pigments are composed of materials of the following mass: Straight press dark brown 22.5 kg / ton dry pulp, direct press acid-resistant scarlet 2.75 kg / ton dry pulp, direct press fast black 1.9 kg / ton dry pulp, direct press indigo 0.035 kg / ton dry pulp, rose essence 0.015 kg / ton dry pulp Dry pulp, acid orange 1.25 kg / ton dry pulp, chemical fixing agent 2.1 kg / ton dry pulp and salt 4.1 kg / ton dry pulp.

[0029] A processing technology of brown translucent wrapping paper, comprising the following steps:

[0030] 1) The raw materials are subjected to pulping treatment, and then enter into the pulp tank;

[0031] 2) After adding the pigment, carry out grinding treatment, then carry out thickening and enter into the slurry forming tank;

[0032] 3) The slurry in the slurry tan...

Embodiment 3

[0037] Such as figure 1 As shown, a coffee-colored translucent wrapping paper is made of raw materials and pigments, the raw materials are composed of 50% coniferous leaves and 50% broadleaf by mass, and the pigments are composed of materials of the following mass: straight press dark brown 25 kg / ton dry pulp, direct press acid-resistant scarlet 3 kg / ton dry pulp, direct press fast black 2 kg / ton dry pulp, direct press indigo 0.04 kg / ton dry pulp, rose essence 0.02 kg / ton dry pulp Dry pulp, acid orange 1.3 kg / ton dry pulp, chemical fixing agent 2.2 kg / ton dry pulp and salt 4.2 kg / ton dry pulp.

[0038] A processing technology of brown translucent wrapping paper, comprising the following steps:

[0039] 1) The raw materials are subjected to pulping treatment, and then enter into the pulp tank;

[0040] 2) After adding the pigment, carry out grinding treatment, then carry out thickening and enter into the slurry forming tank;

[0041] 3) The slurry in the slurry tank flows in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap