Modified Y zeolite and preparation method thereof and cracking catalyst containing modified Y zeolite

A catalyst and zeolite technology, applied in physical/chemical process catalysts, molecular sieve catalysts, cracking and other directions, can solve the problem of low gasoline yield of modified Y zeolite cracking catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

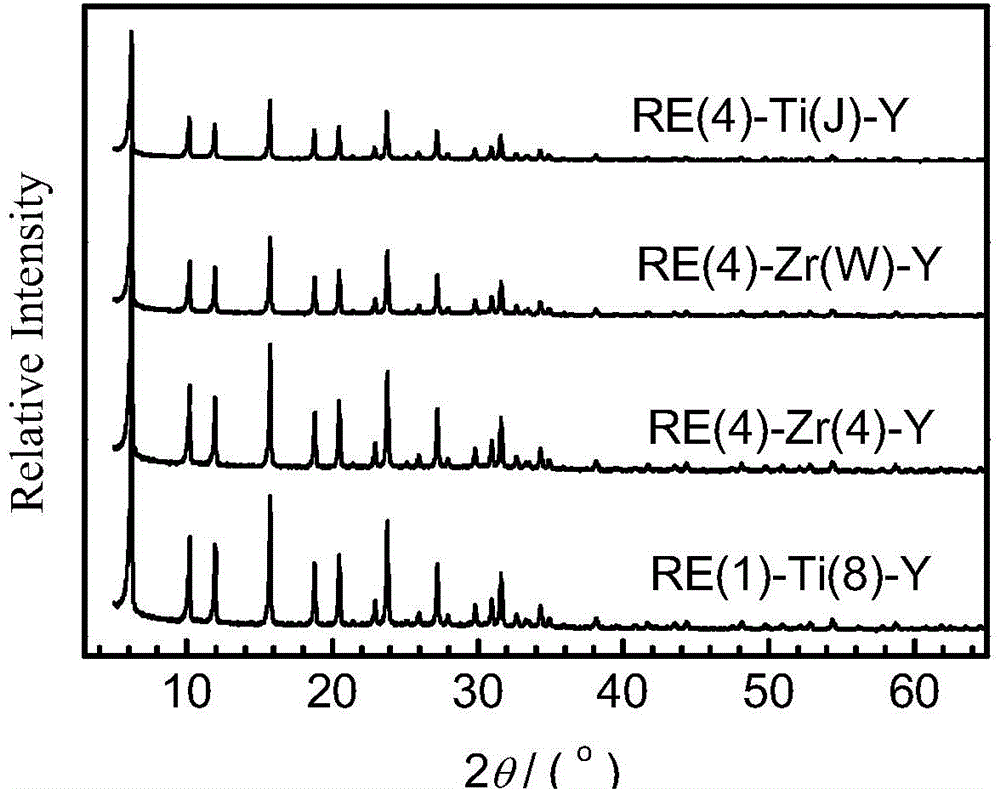

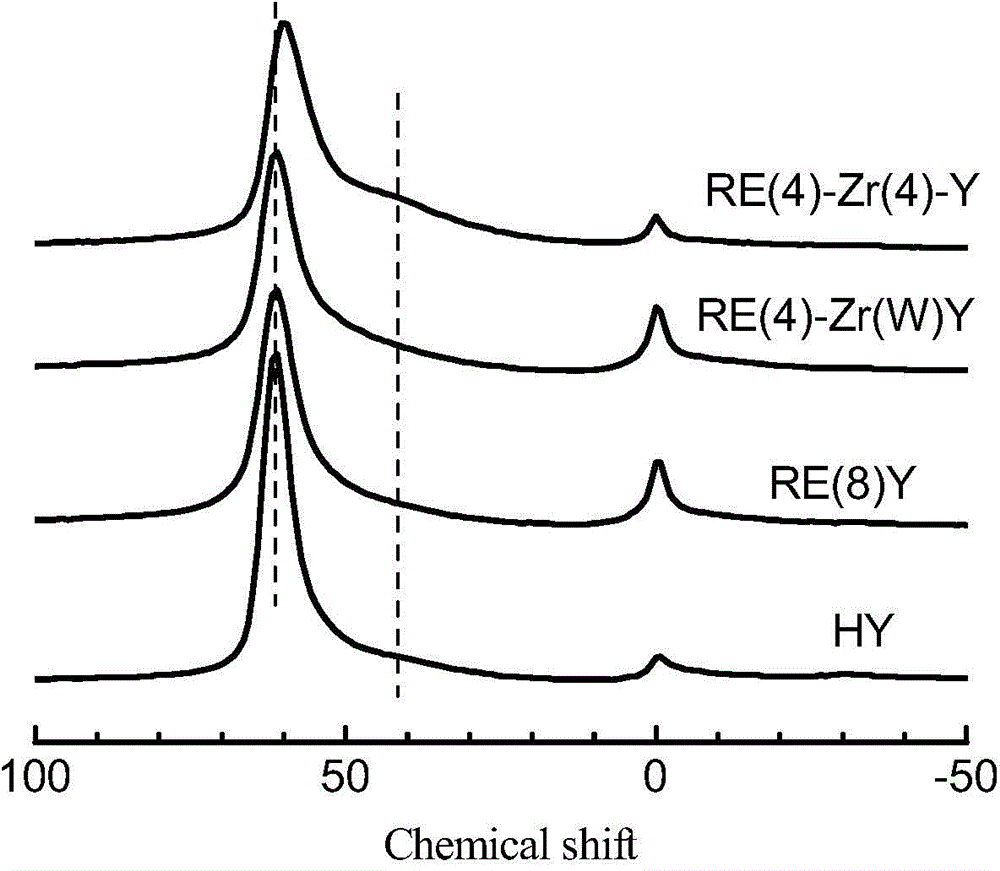

Image

Examples

Embodiment 1

[0060] At room temperature, get 200g NaY zeolite (dry basis 75% by weight), after beating with 1500g deionized water, add 45 grams (NH 4 ) 2 SO 4 and 45 mL RECl 3 Solution (270 g / L), rare earth salt (in RE 2 o 3 The weight ratio of ammonium salt: NaY zeolite: deionized water is 0.08:0.3:1; After washing with deionized water, the filter cake was roasted at 600° C. in 100% water vapor for 2 hours to obtain a rare earth modified Y zeolite with a water content of 3% by weight.

[0061] 5.23g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O was dissolved in 200g ethanol (purity 99.9%) to make an impregnating liquid, and the obtained impregnating liquid was mixed evenly with the Y zeolite after the above treatment, kept at room temperature for 1 h, then the resulting product was mixed with 800 ml ethanol, transferred to an autoclave, and washed Inject nitrogen to make the pressure 0.5MPa, then keep at room temperature for 12 hours, filter, dry at 100°C for 24 hours, and bake at 500°C ...

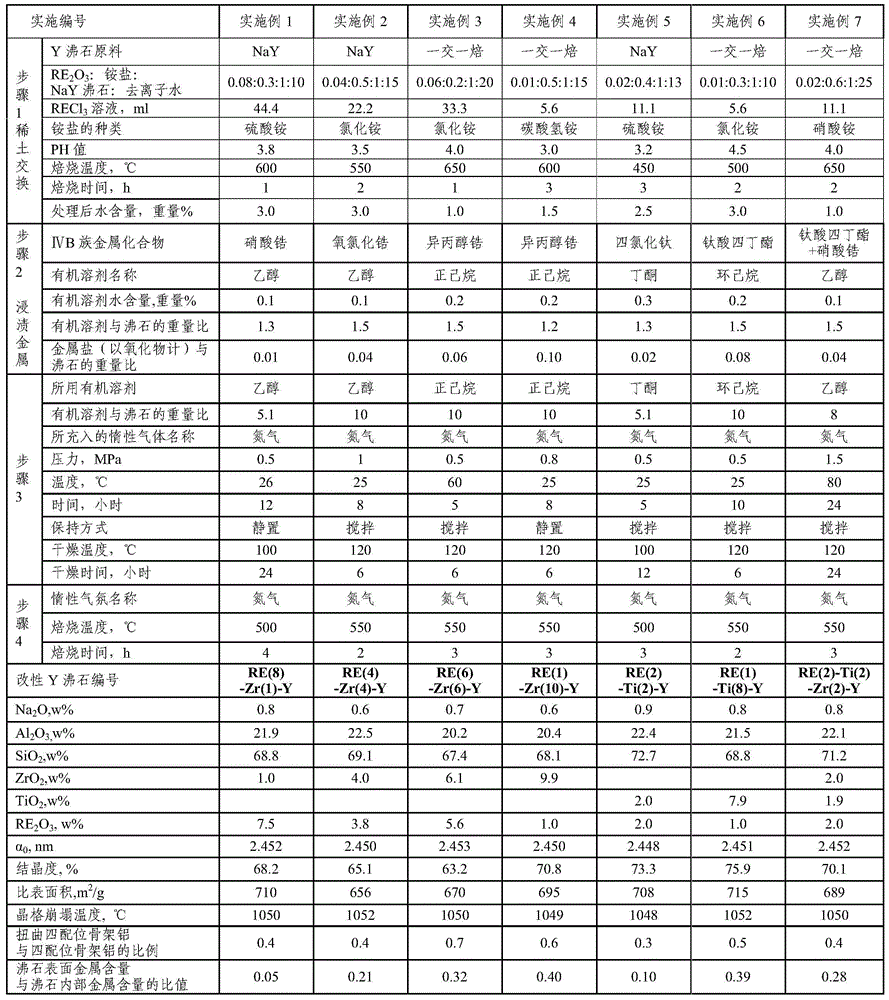

Embodiment 2~7

[0063] The molecular sieves were prepared according to the method provided by the present invention, and the operating conditions and properties of the products are shown in Table 2.

[0064] Table 2

[0065]

[0066] * In Tables 2 to 8, w% means % by weight and is percentage by weight.

Embodiment 8~14

[0086] Examples 8-14 illustrate the hydrothermal stability of the modified Y zeolite prepared in the present invention.

[0087] After aging the modified Y zeolites prepared in Examples 1 to 7 for 12 hours at 800°C and 100% water vapor, measure their crystallinity and specific surface area, and calculate the crystallization retention and specific surface area retention. The results are listed in Table 4.

[0088] And carry out light oil micro-reactivity evaluation, adopt the standard method of RIPP92-90 (see " petrochemical analysis method " (RIPP test method) Yang Cuiding etc. edit, Science Press, published in 1990) evaluate the light oil micro-reactivity of sample, The catalyst loading was 5.0g, the reaction temperature was 460°C, and the raw oil was straight-run light diesel oil with a distillation range of 235-337°C. The product composition was analyzed by gas chromatography, and the light oil microreactivity was calculated according to the product composition. The results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com