A kind of preparation method of high-yield l-sodium antimony tartrate

A technology of sodium antimony tartrate and sodium hydrogen tartrate, which is applied in the field of preparation of sodium antimony tartrate, can solve the problems of uncomplicated, only 80% yield, and inability to obtain crystals, and achieve the effect of stable quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

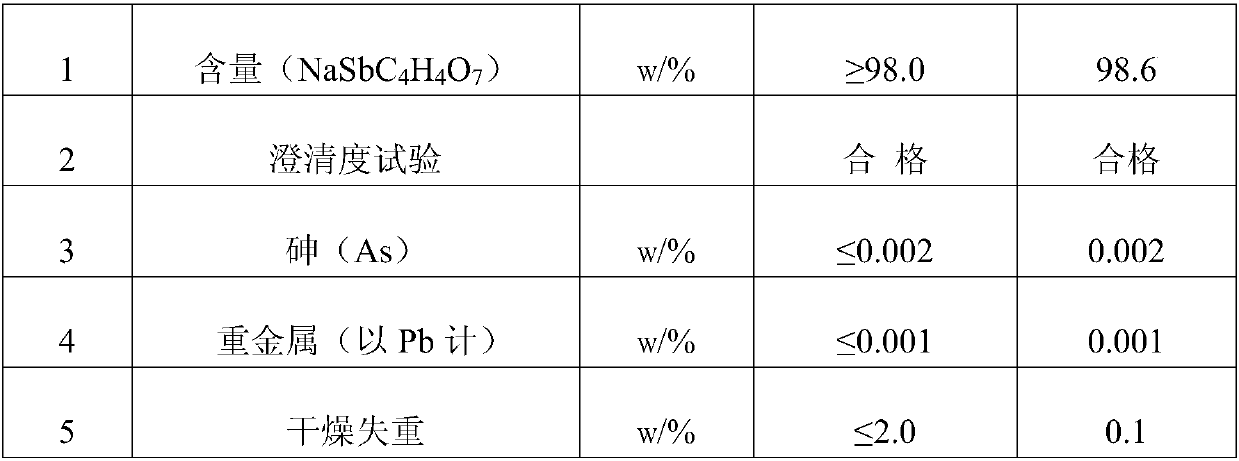

Embodiment 1

[0020] Weigh 200g of L-sodium hydrogen tartrate and slowly add it to 1500mL of deionized water, and stir while heating. After it is completely dissolved, continue to heat the solution to 90°C, then add 160g of antimony trioxide solid in batches, and stir while adding. After the addition of antimony trioxide, continue to react in boiling state for 2 hours. After the reaction is complete, add 0.016g of sodium sulfide (made into an aqueous solution) to remove arsenic. After stirring for 20 minutes, filter with filter paper. Measure the clarity of the filtrate after filtration. After passing the test, heat and concentrate When the density reaches 1.70g / mL (70°C), cool naturally to room temperature, measure 300ml of absolute ethanol and pour it into a beaker, slowly add the concentrated solution, stir while adding, a large amount of white L-sodium antimony tartrate solid is precipitated, centrifuged for 10min Finally, the solid was dried at 80°C for 10 hours to obtain 333g of the sa...

Embodiment 2

[0024] Weigh 300g of L-sodium hydrogen tartrate and slowly add it to 3000mL of deionized water, and stir while heating. After it is completely dissolved, continue to heat the solution to 80°C, then add 240g of antimony trioxide solid in batches, and stir while adding. After the addition of antimony trioxide, continue to react in boiling state for 6 hours. After the reaction is complete, add 0.1g sodium sulfide (made into an aqueous solution) to remove arsenic. After stirring for 20 minutes, filter it with filter paper. Measure the clarity of the filtrate after filtration. After passing the test, heat and concentrate When the density reaches 1.50g / mL (90°C), cool naturally to room temperature, measure 400ml of absolute ethanol and pour it into a beaker, slowly add the concentrated solution, stir while adding, a large amount of white solid will precipitate out, centrifuge for 10min, and put the solid in Dry at 120° C. for 6 hours to obtain 501 g of the sample (theoretical calcula...

Embodiment 3

[0028] Add 165kg of deionized water to the reaction kettle, then add 33kg of L-sodium hydrogen tartrate in batches, turn on the steam heating, after it is completely dissolved, continue to heat the solution to 90°C, and then add 25kg of antimony trioxide solid in batches, while adding While stirring. After the addition of antimony trioxide, continue to react in a boiling state for 4 hours. After the reaction is complete, add 12.5 g of sodium sulfide (made into an aqueous solution) to remove arsenic. After stirring for 20 minutes, filter it with a four-layer filter bag. Measure the clarity of the filtered filtrate. Qualified, add 150g of activated carbon to re-filter, after the obtained filtrate has qualified clarity, heat and concentrate to a density of 1.60g / mL (85°C), then naturally cool to room temperature, then add 40kg of absolute ethanol to another reaction kettle, and the cooled The concentrated solution was added to absolute ethanol in batches, and stirred while adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com