Even-air-volume blood curd drying mechanism

A drying mechanism and technology of blood tofu, which is applied in dryers, dryers of static materials, drying and other directions, can solve the problems of different drying effects of blood tofu, unfavorable mass production, unfavorable drying time, etc. Conducive to drying time, mass production, convenient and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

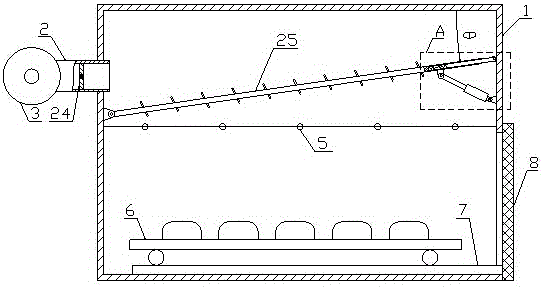

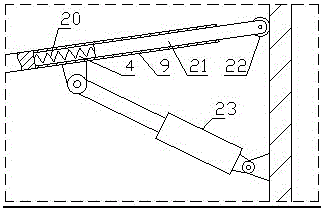

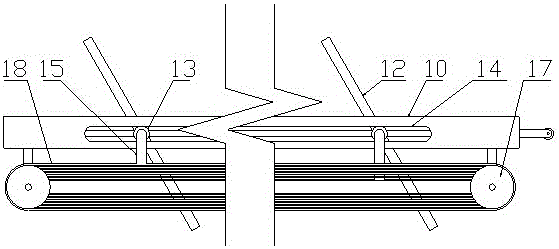

[0018] Embodiment of the present invention: a blood tofu drying mechanism with uniform air volume, such as Figure 1-5 As shown, a drying room 1 is included, and the drying room 1 is connected to the hot air blower 3 through the air supply pipe 2; the drying room 1 is also provided with an oblique air distribution mechanism 25, and a temperature sensor 5 is distributed below the air distribution mechanism 25. , below the temperature sensor 5 is provided with a feeding trolley 6, and the feeding trolley 6 is connected with the feeding guide rail 7, and one end of the feeding guide rail 7 is provided with a feeding door 8; There are also side beams 10, and the middle part of the air distribution plate 9 is also provided with an air supply port 11, and the air supply port 11 is distributed with an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com