An automatic cloth feeding device for a double overlock machine

A cloth feeding device and seaming machine technology, which is applied in transportation and packaging, thin material processing, winding strips, etc., can solve the problems of low utilization rate of floor space, large size of cloth feeding device, inconvenient operation for workers, etc. , to achieve the effects of improving production efficiency, compact structure, and reasonable disassembly and assembly positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

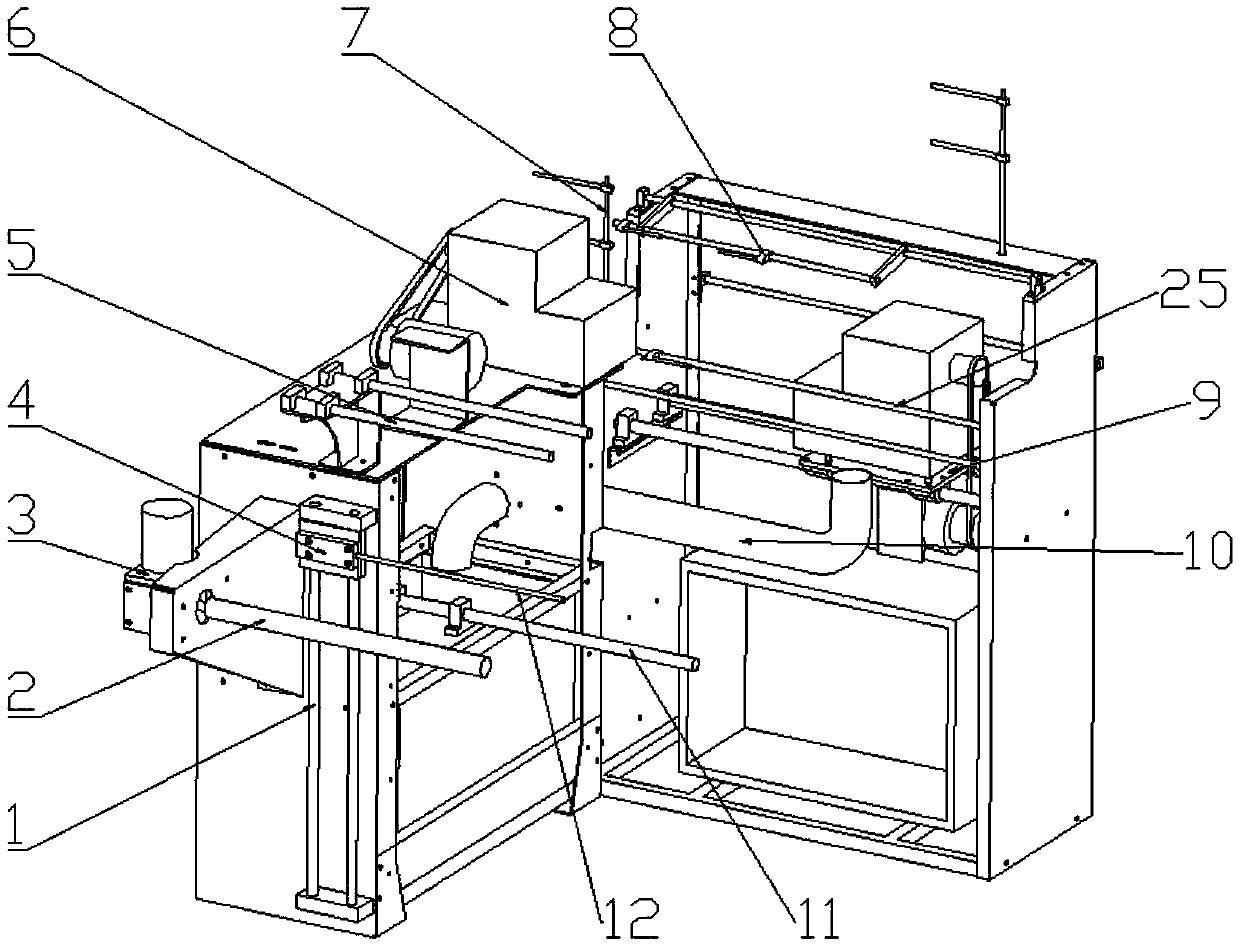

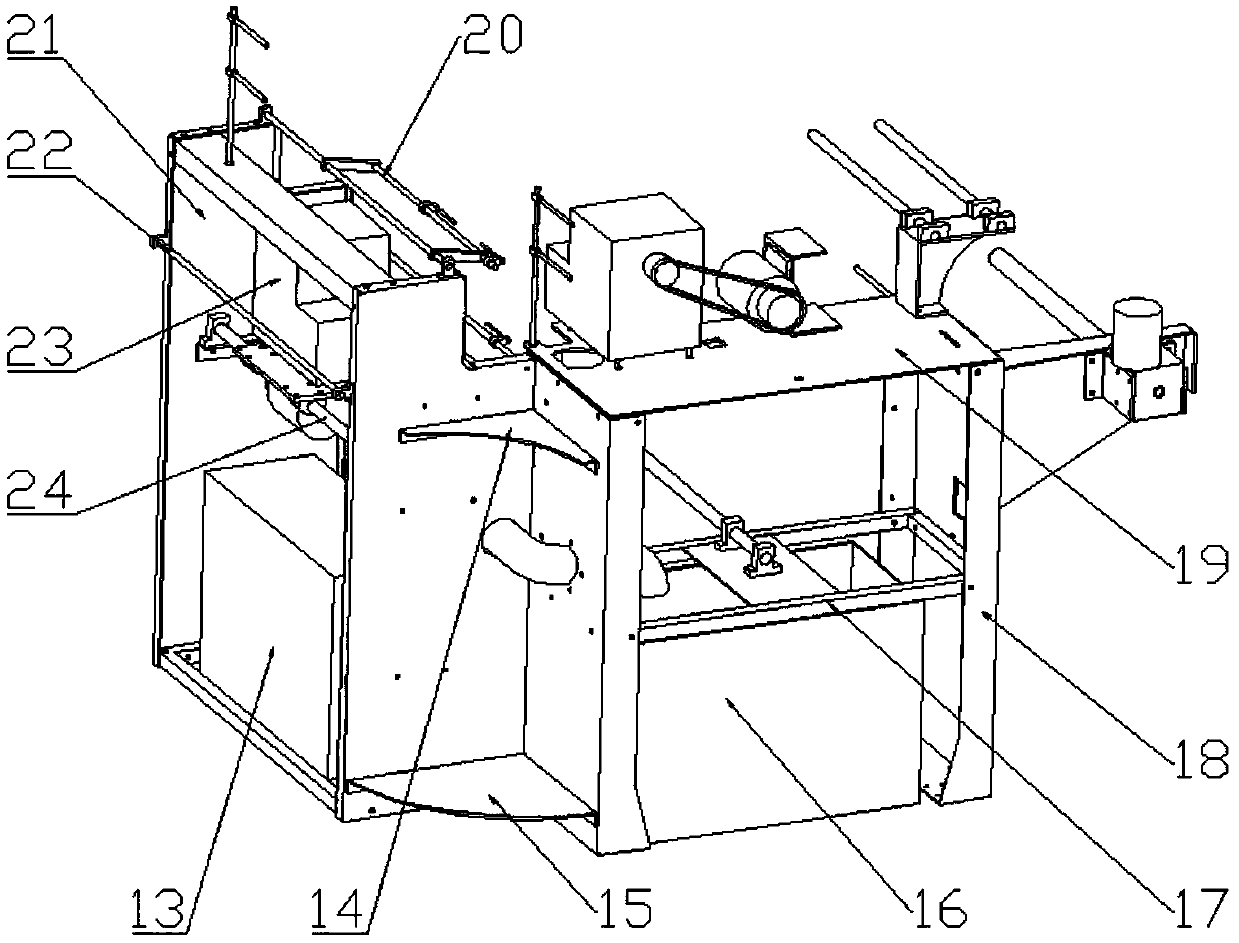

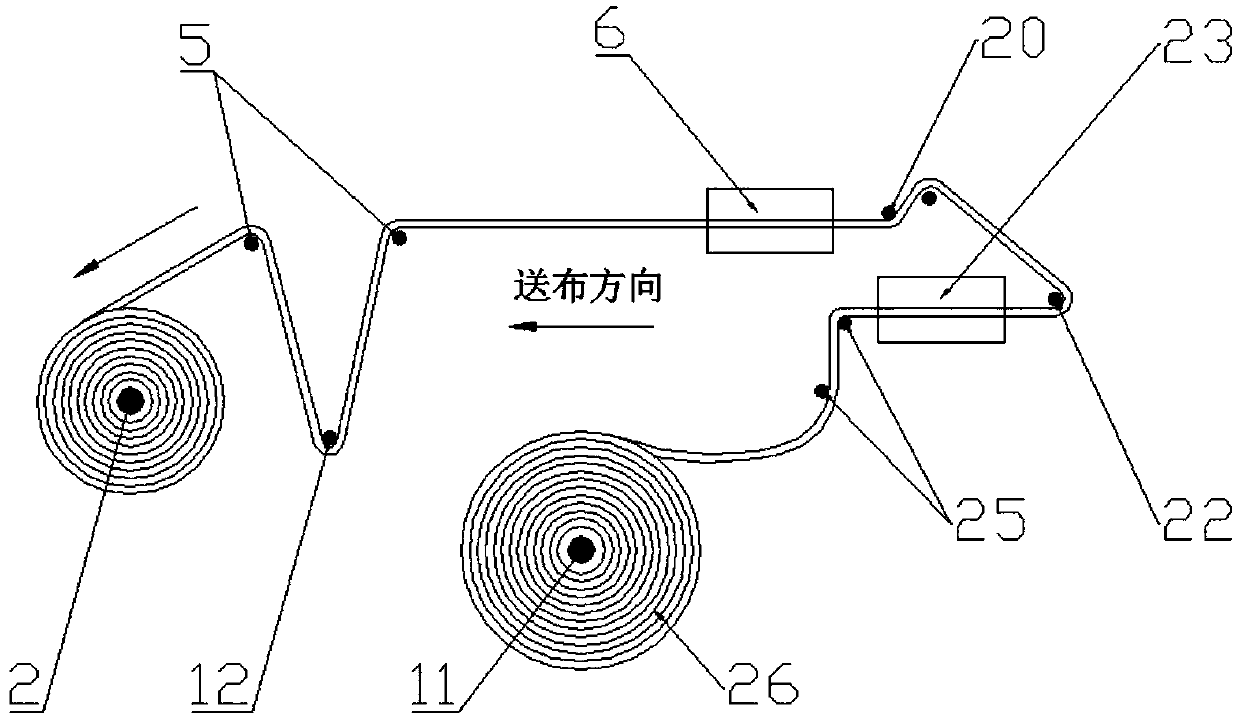

[0021] like figure 1 As shown, an automatic cloth feeding device for a double overlock machine is characterized in that the frame includes two high brackets 21 and short brackets 18 arranged in an L shape, and the counterweight 4 of the tensioning mechanism is installed on the vertical guide rail 1, which can Swipe up and down. The vertical guide rail 1 is installed on the side of the short bracket 18 through the mounting seat, and is kept parallel to the side of the short bracket 18. The distance between the two is 5cm-8cm, providing space for the tension mechanism counterweight 4 to slide up and down, and the gravity rod 12 is fixed on the tension mechanism counterweight. 4, slide up and down along the vertical guide rail 1 along with the tension mechanism counterweight 4. The reduction motor 3 provides winding power for the cloth boom 2, and is installed together with the cloth boom 2, and fixed on the triangular sheet metal part, the triangular sheet metal part is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com