Integrated motor driver system integrating motor and controller

A motor driver and controller technology, applied in the direction of connection with control/drive circuits, electric components, synchronous motors with static armatures and rotating magnets, etc., can solve the problem of restricting the service life of motors and inconvenient speed regulation of AC asynchronous motors , low efficiency and other problems, to achieve the effect of saving materials, reducing volume and weight, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

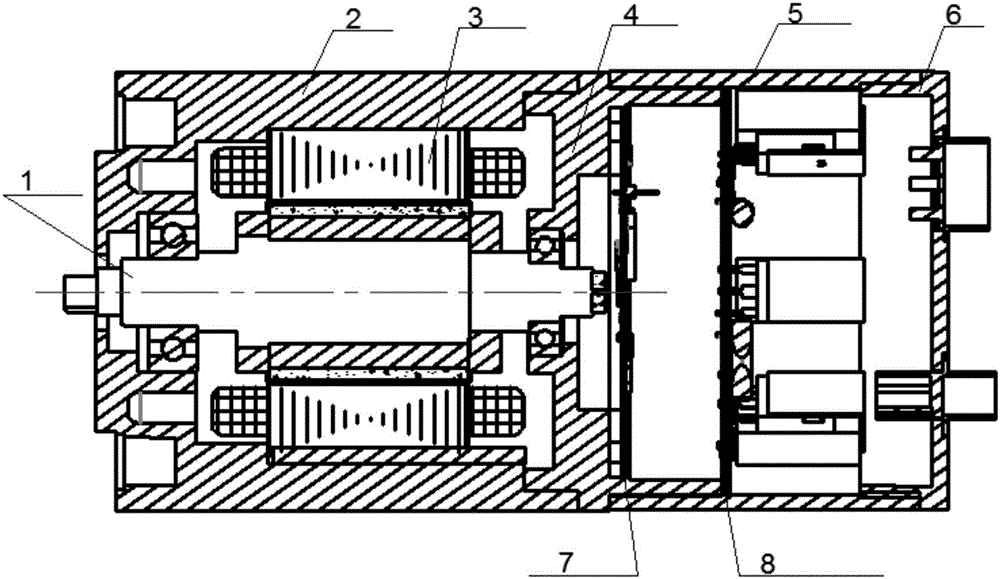

[0027] Such as Figure 1-7 As shown, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

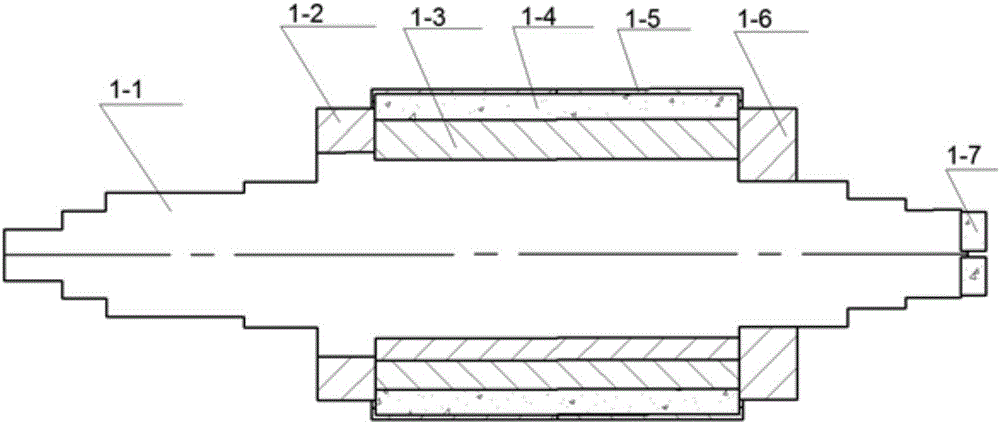

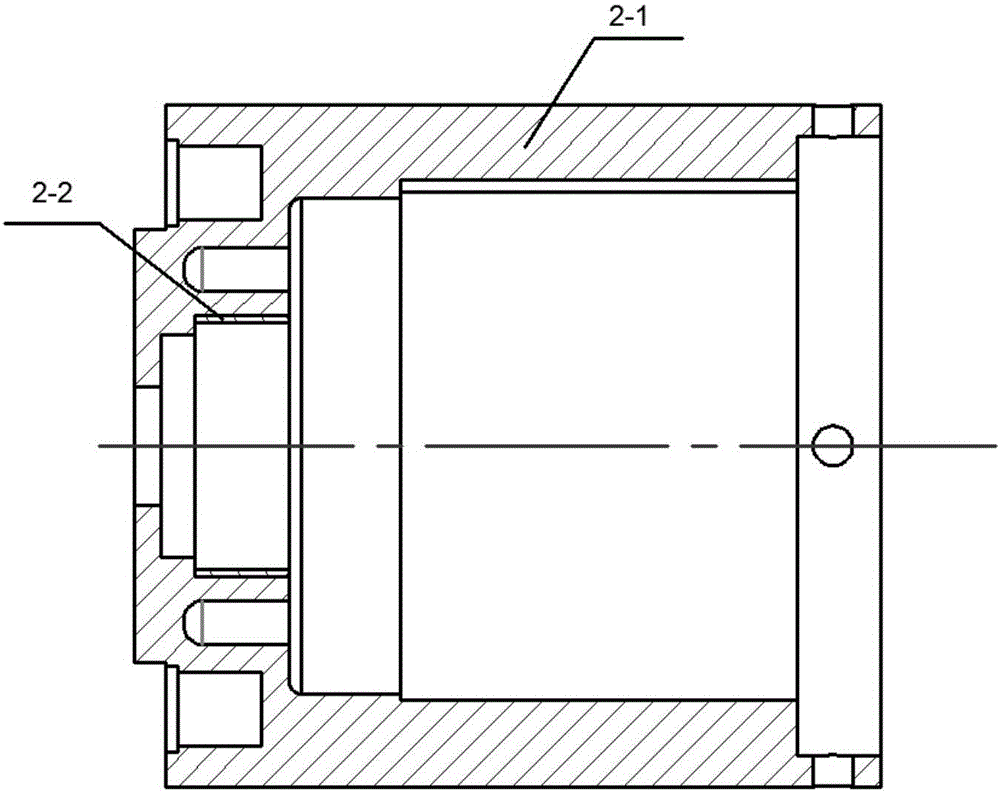

[0028] Such as figure 1 As shown, an integrated motor drive system integrating a motor and a controller consists of a rotor assembly 1, a housing assembly 2, a stator assembly 3, a rear cover assembly 4, a rear housing 5, a rear cover 6, a control board 7, The driver board 8 is composed. Such as figure 2 As shown, the rotor assembly 1 consists of a shaft 1-1, a front deweighting ring 1-2, a rotor yoke 1-3, a magnet 1-4, a rotor sheath 1-5, a rear deweighting ring 1-6, and a tracking magnetic Steel 1-7 composition. The end of shaft 1-1 is milled with a concave surface, and the boss of the tracking magnet 1-7 is aligned with the concave surface of the end of shaft 1-1. The middle part of shaft 1-1 is milled with two symmetrically distributed flat key grooves, shaft 1-1 and rotor magnet The yoke 1-3 is connected by two ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap