Method for reducing corrosion of chimney of FCC (fluid catalytic cracking) flue gas desulfurization device

A desulfurization device and chimney technology, applied in the chemical industry, can solve the problems of difficult maintenance of the anti-corrosion coating and high cost of replacing materials, and achieve the effects of low cost, simple operation and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

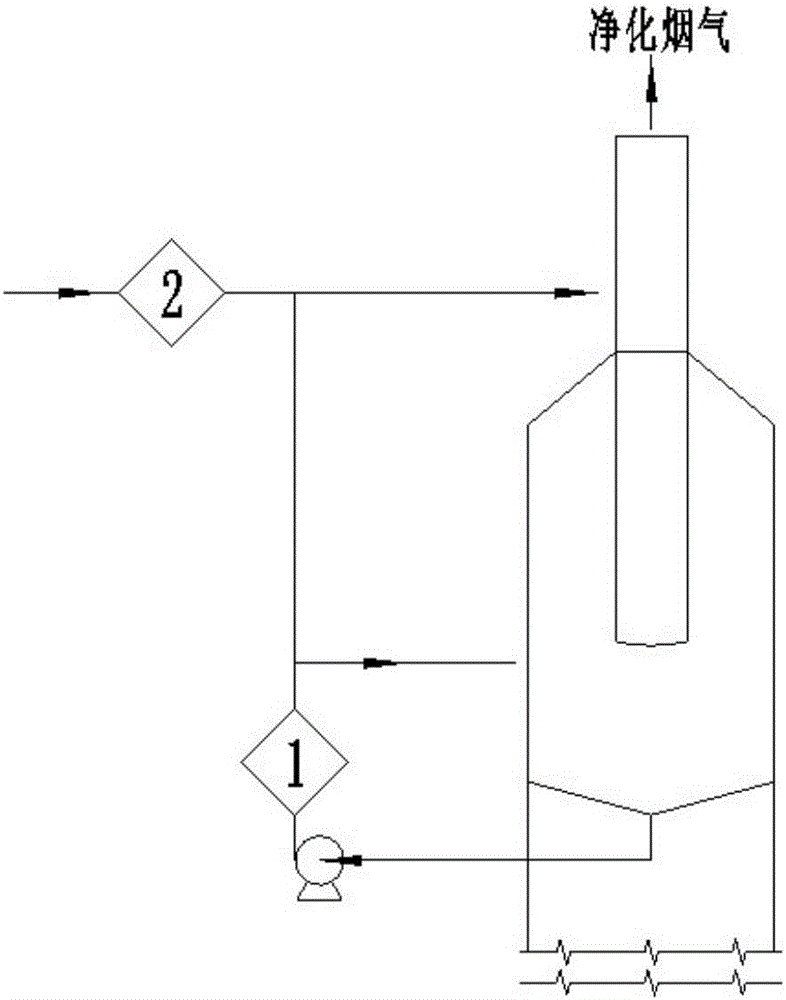

[0046] The washing device used in this example is as figure 1 As shown, the lye from the washing liquid pipeline 1 is mixed with the water from the water pipeline 2 and then enters the chimney. groove. The specific process is as follows.

[0047] The catalytic cracking flue gas desulfurization unit of a refinery adopts EDV wet scrubbing technology. The material of the chimney part of the cylinder is Q345R+S30403. The device has been in operation for about one year, and the upper cylinder of the chimney is found to be corroded and perforated. The flue gas flow rate of the scrubber is 170502Nm 3 / h (wet basis), the inner diameter of the chimney is 2300mm. During the maintenance period of the device, the chimney will be replaced as a whole, and the material will not change.

[0048] Adopt method described in the present invention, inject the caustic soda solution of 50 ℃ at the chimney top, control pH to be about 9, control the flow of chimney top washing liquid to be 2~3m 3...

Embodiment 2

[0052] The catalytic cracking flue gas desulfurization unit of a refinery adopts EDV wet scrubbing technology. The material of the chimney part of the cylinder is Q345R+S30403. The device has been in operation for about one year, and the upper cylinder of the chimney is found to be corroded and perforated. The flue gas flow rate of the scrubber is 170502Nm 3 / h (wet basis), the inner diameter of the chimney is 2300mm. During the maintenance period of the device, the chimney will be replaced as a whole, and the material will not change.

[0053] Adopt method described in the present invention, inject the caustic soda solution of 50 ℃ at the chimney top, control pH to be about 9, control the flow of chimney top washing liquid to be 2~3m 3 / h, a 4-5 mm water film is formed on the inner wall of the chimney, and the washing liquid flowing down the inner wall of the chimney is collected into the recirculation tank of the filter module. After one month of operation, the annual cost...

Embodiment 3

[0055] The catalytic cracking flue gas desulfurization unit of a refinery adopts EDV wet scrubbing technology. The material of the chimney part of the cylinder is Q345R+S30403. The device has been in operation for about one year, and the upper cylinder of the chimney is found to be corroded and perforated. The flue gas flow rate of the scrubber is 170502Nm 3 / h (wet basis), the inner diameter of the chimney is 2300mm. During the maintenance period of the device, the chimney will be replaced as a whole, and the material will not change.

[0056] Adopt method described in the present invention, inject the caustic soda solution of 50 ℃ at the chimney top, control pH to be about 9, control the flow of chimney top washing liquid to be 2~3m 3 / h, a 2-3 mm water film is formed on the inner wall of the chimney, and the washing liquid flowing down the inner wall of the chimney is collected into the recirculation tank of the filter module. After one month of operation, the annual cost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com