Soldering furnace with automatic slag removal function and working method thereof

An automatic slag removal and soldering furnace technology, which is applied in tin feeding devices, manufacturing tools, metal processing, etc., can solve problems such as the influence of welding fixed length devices, the inability to automatically remove tin slag, and the inability to automatically replenish tin liquid, etc., to achieve improved soldering performance. The effect of improving quality, preventing drastic temperature fluctuations, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

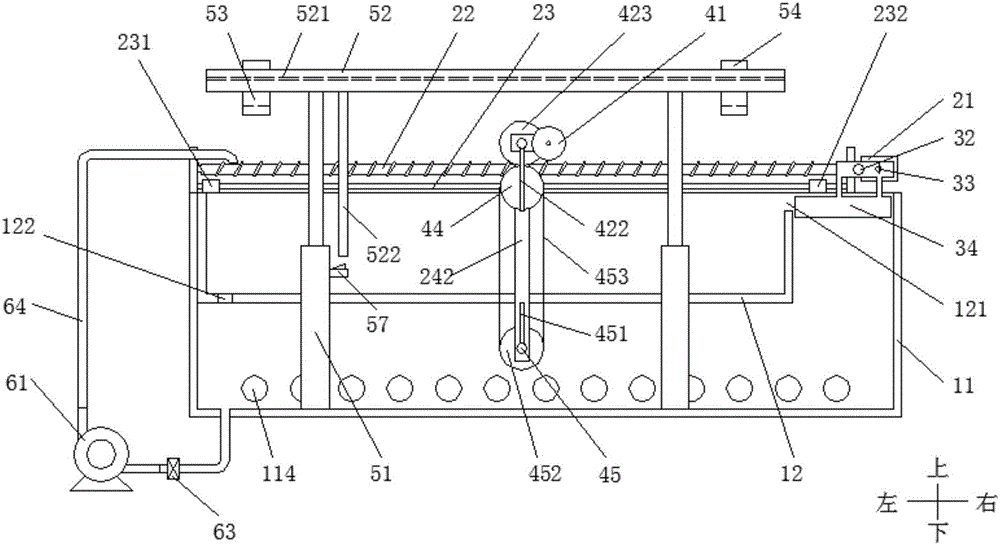

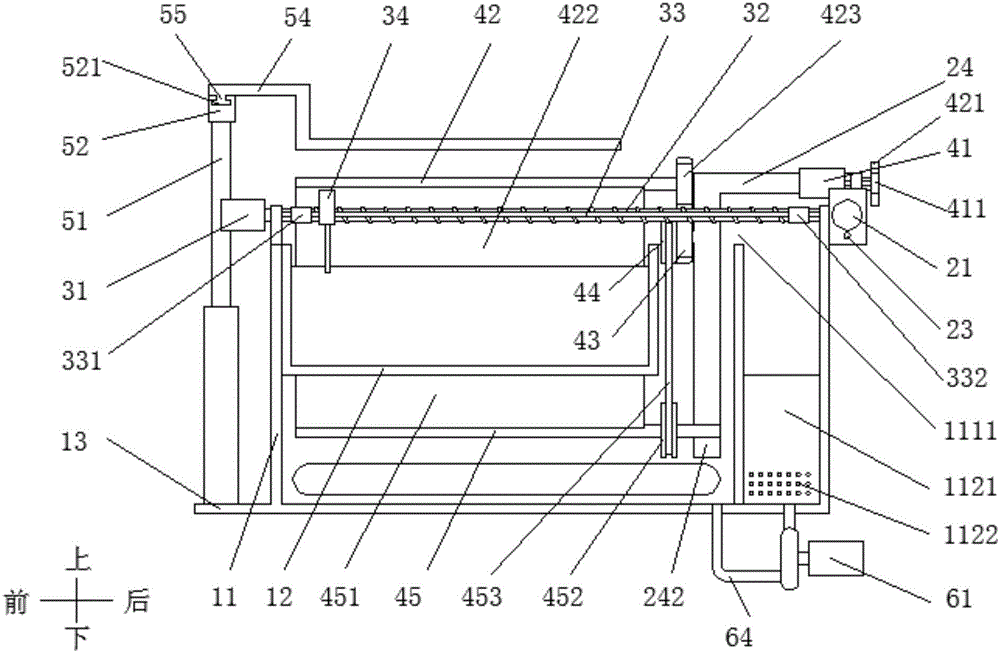

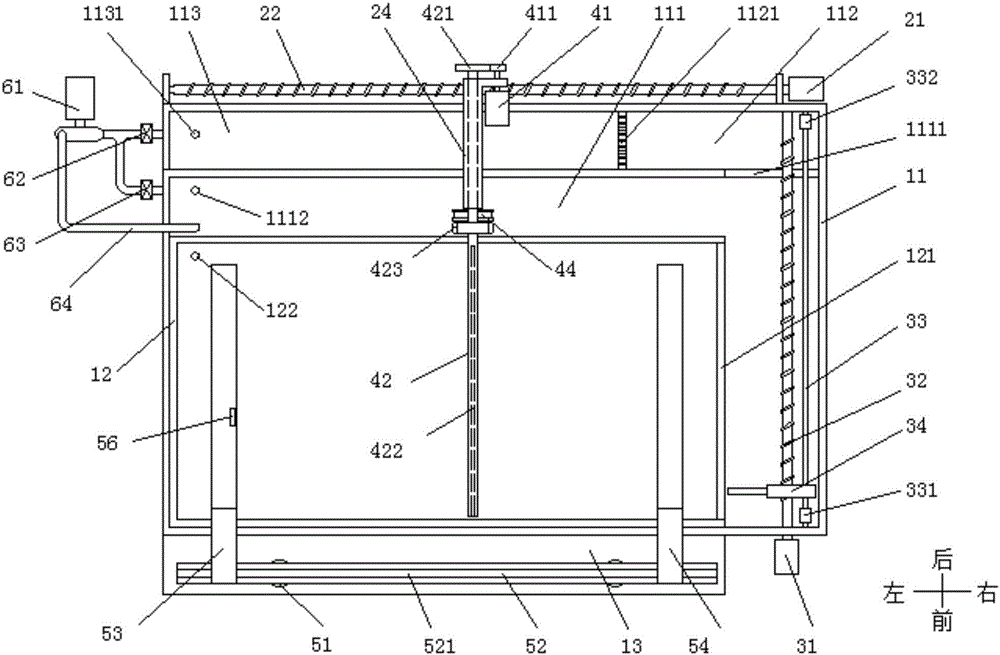

[0050] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0051] In addition, it should be noted that, unless otherwise specified or pointed out, the terms "first", "second", "front", "rear", "left", "right", and "up" may be involved in the specification. Descriptions such as "under" and "under" are only used to distinguish each component, element, step, etc. in the specification, rather than used to indicate the logical relationship or sequence relationship between each component, element, step, etc.

[0052] The related words of "forward work" and "reverse work" of the transverse motor 21, the longitudinal motor 31 and the slag removal motor 41 are only used for convenience of description, and do not represent the specific ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com