Horizontal machining center with tool changer

A technology of exchange device and machining center, which is used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the processing accuracy of parts products cannot meet the requirements, the overall accuracy of the tool arm type tool magazine is reduced, and the quality of processing is affected. And reliability and other issues, to achieve the effect of simple structure, easy installation, improved quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

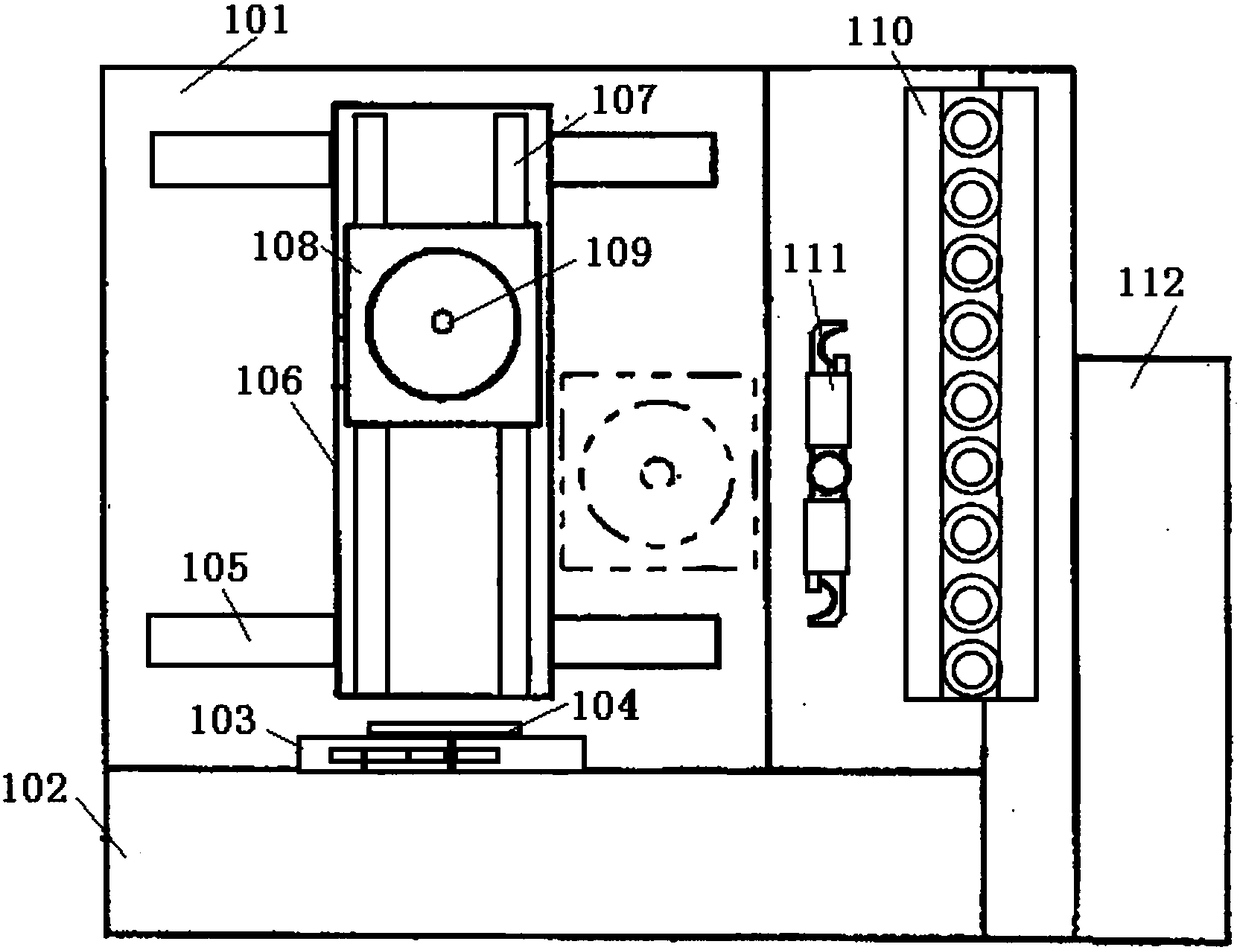

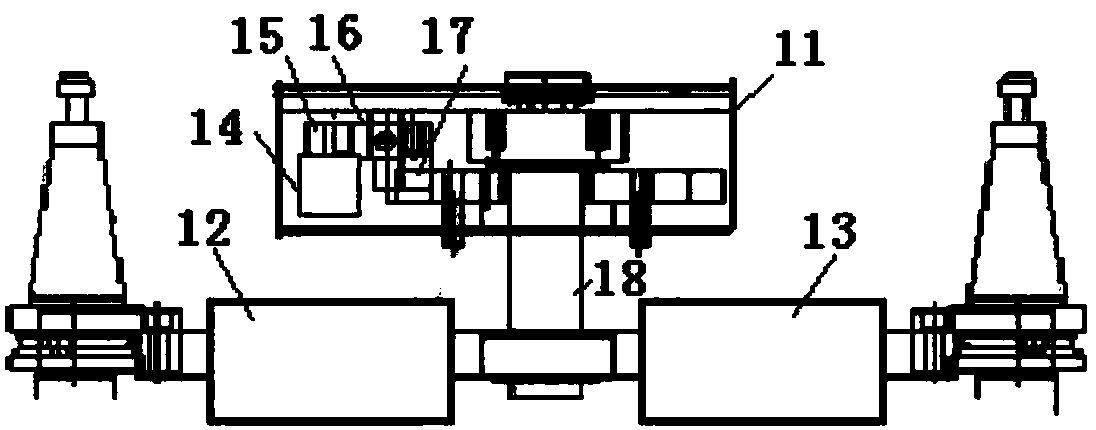

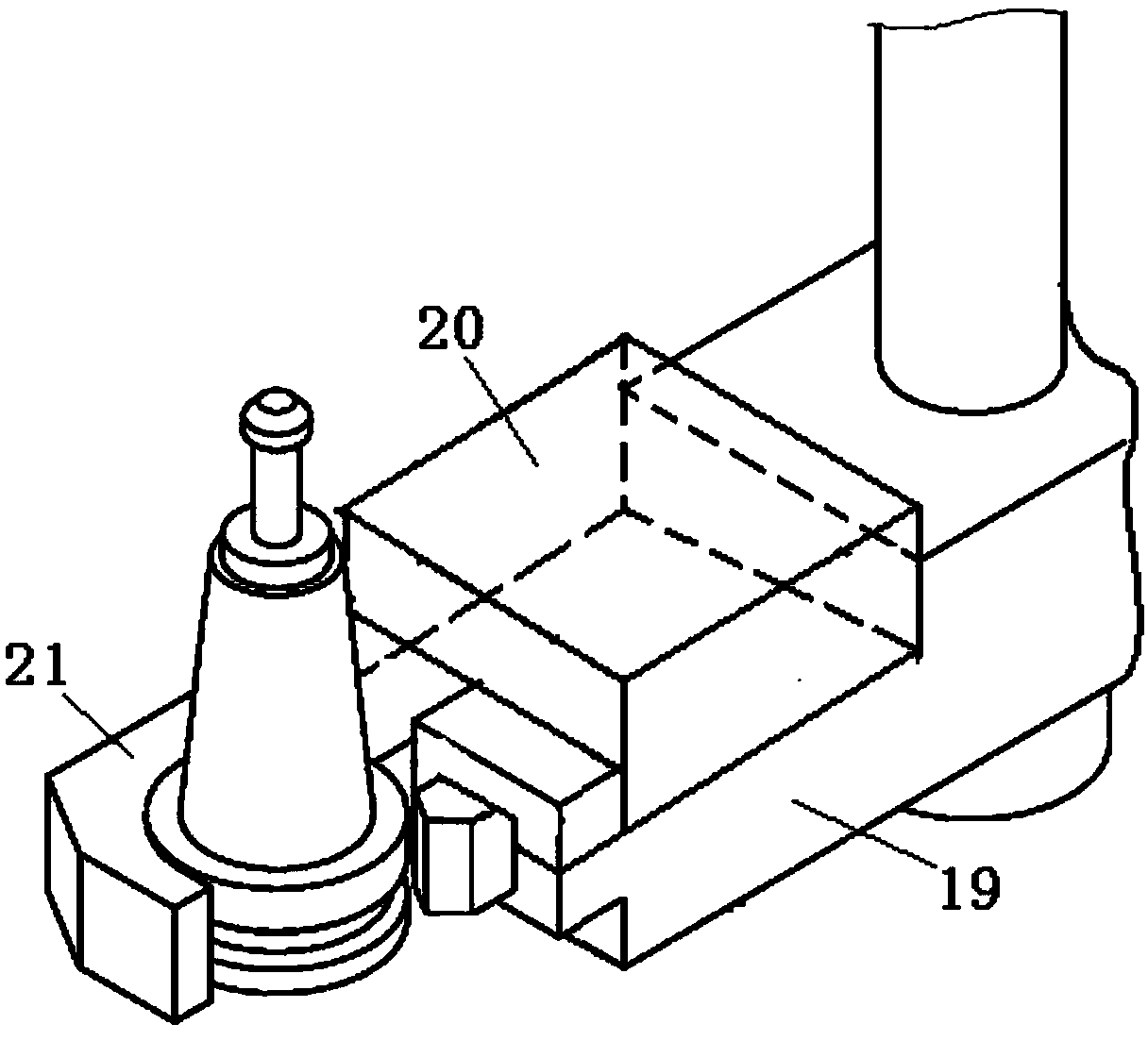

[0024] see Figure 1 to Figure 4 , shows a horizontal machining center with a tool magazine exchange device of the present invention, including a frame body 101 and a base 102, the upper surface of the base 102 is provided with a processing table 103, and the processing table 103 is provided with a workpiece to be processed For the clamping fixture 104, two transverse guide rails 105 are arranged in the frame body 101, and a processing seat 106 is arranged on the transverse guide rail 105 for lateral movement, and the processing seat 106 is provided with two vertical guide rails 107, one The headstock 108 is mounted on the vertical guide rail 107 so as to be movable vertically, and a toolholder for the fixed rotation of the tool 109 is provided in the middle of the headstock 108 .

[0025] One side in the frame body 101 is provided with a rotary tool magazine 110, and the rotary tool magazine 110 is selected as a disc type rotary tool magazine, and a plurality of cutting tools...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com