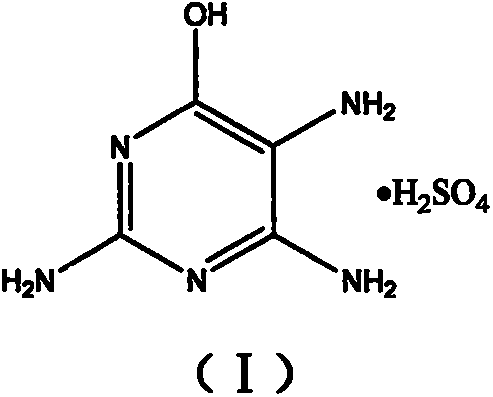

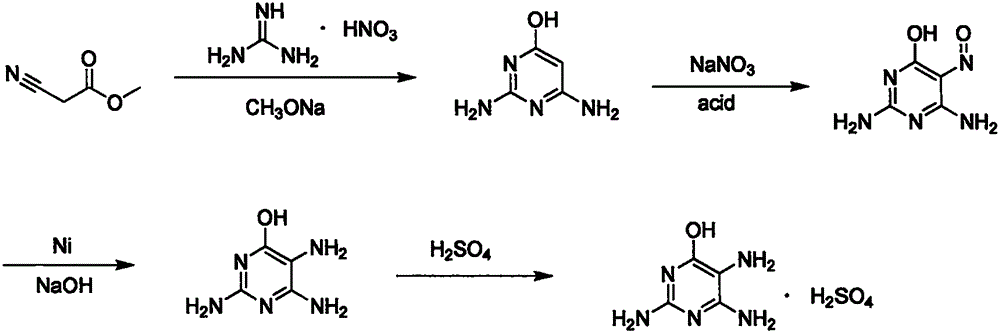

Method for effectively reducing nickel remaining in 2,4,5-triamino-6-hydroxypyrimidinesulfate

A technology of hydroxypyrimidine and triamino, which is applied in the field of preparation of anti-herpes drugs, can solve problems affecting product yield and product loss, and achieve good temperature stability, reduced hazards, good storage stability and operational safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0028] Add 56.3g of 2,4-diamino-5-nitroso-6-hydroxypyrimidine into the hydrogenation kettle, then add 800-1000g of water, start stirring, add 12-14g of sodium hydroxide, adjust ph=12-13 , then add 0.51g of active nickel, start stirring, replace the vacuum with nitrogen for 3 times, then replace the vacuum with hydrogen for 3 times, fill in hydrogen to make the pressure rise to 0.2-0.24Mpa, raise the temperature to 68 degrees, when the pressure rises to 0.4- Turn off the hydrogen at 0.42Mpa, stir for 1-2min, the pressure does not drop significantly, the temperature in the reactor is 85-90 degrees, filter and separate, add 0.31g organic sulfur polymer heavy metal scavenger TMT10 to the filtrate, heat to 70-80 degree, stirred for 65min, hot filtered, added dropwise 70-80g of 50% sulfuric acid to the green leaves for acidification, adjusted the pH to between 1-2, continued to stir for 20min, filtered, and dried to obtain light yellow 2,4,5- Triammonium 6-hydroxypyrimidine sulfate ...

Embodiment ( 2

[0030] Add 56.5g of 2,4-diamino-5-nitroso-6-hydroxypyrimidine into the hydrogenation kettle, then add 800-1000g of water, start stirring, add 12-14g of sodium hydroxide, adjust ph=12-13 , then add 0.5g of active nickel, start stirring, replace the vacuum with nitrogen for 3 times, then replace the vacuum with hydrogen for 3 times, fill in hydrogen to make the pressure rise to 0.2-0.24Mpa, raise the temperature to 68 degrees, when the pressure rises to 0.4- Turn off the hydrogen at 0.42Mpa, stir for 1-2min, the pressure does not drop significantly, the temperature in the reactor is 85-90 degrees, filter and separate, add 0.26g organic sulfur polymer heavy metal scavenger TMT18 to the filtrate, heat to 70-80 degree, stirred for 90min, hot filtered, added dropwise 70-80g of 50% sulfuric acid to the green leaves for acidification, adjusted the pH to between 1-2, continued to stir for 20min, filtered, and dried to obtain light yellow 2,4,5- 72.9 g of triamino-6-hydroxypyrimidine su...

Embodiment ( 3

[0032] Add 56.3g of 2,4-diamino-5-nitroso-6-hydroxypyrimidine into the hydrogenation kettle, then add 800-1000g of water, start stirring, add 12-14g of sodium hydroxide, adjust ph=12-13 , then add 0.52g of active nickel, start stirring, replace the vacuum with nitrogen for 3 times, then replace the vacuum with hydrogen for 3 times, fill in hydrogen to make the pressure rise to 0.2-0.24Mpa, raise the temperature to 68 degrees, when the pressure rises to 0.4- Turn off the hydrogen at 0.42Mpa, stir for 1-2min, the pressure does not drop significantly, the temperature in the reactor is 85-90 degrees, filter and separate, add 0.29g organic sulfur polymer heavy metal scavenger EDTC to the filtrate, heat to 70-80 degree, stirred for 85min, filtered hot, added dropwise 70-80950% sulfuric acid to the green leaves for acidification, adjusted the pH to between 1-2, continued to stir for 20min, filtered, and dried to obtain light yellow 2,4,5- 71.8g of triamino-6-hydroxypyrimidine sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com