Embedded rolling-up device for water-jet loom

A water-jet loom, embedded technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of complex procedures, offset, space waste, etc., and achieve convenient, economical and practical operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

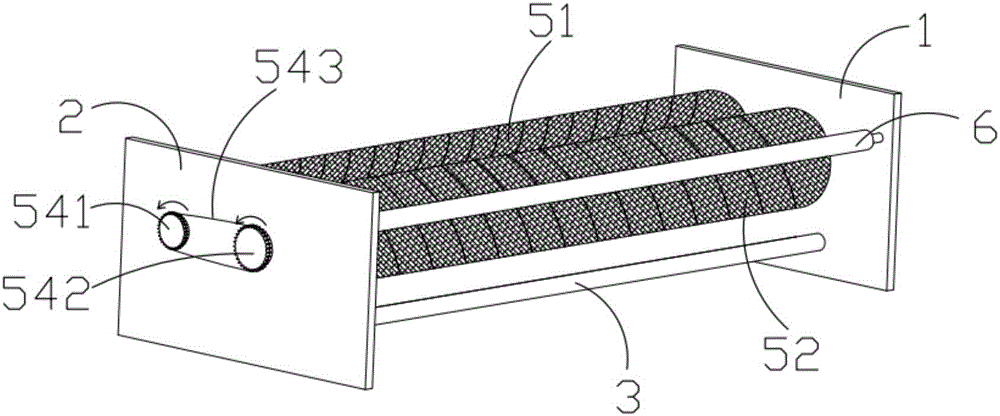

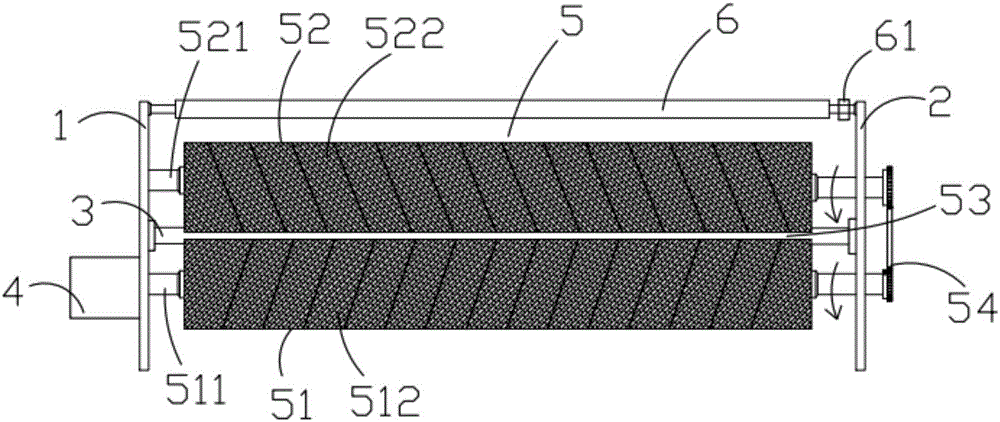

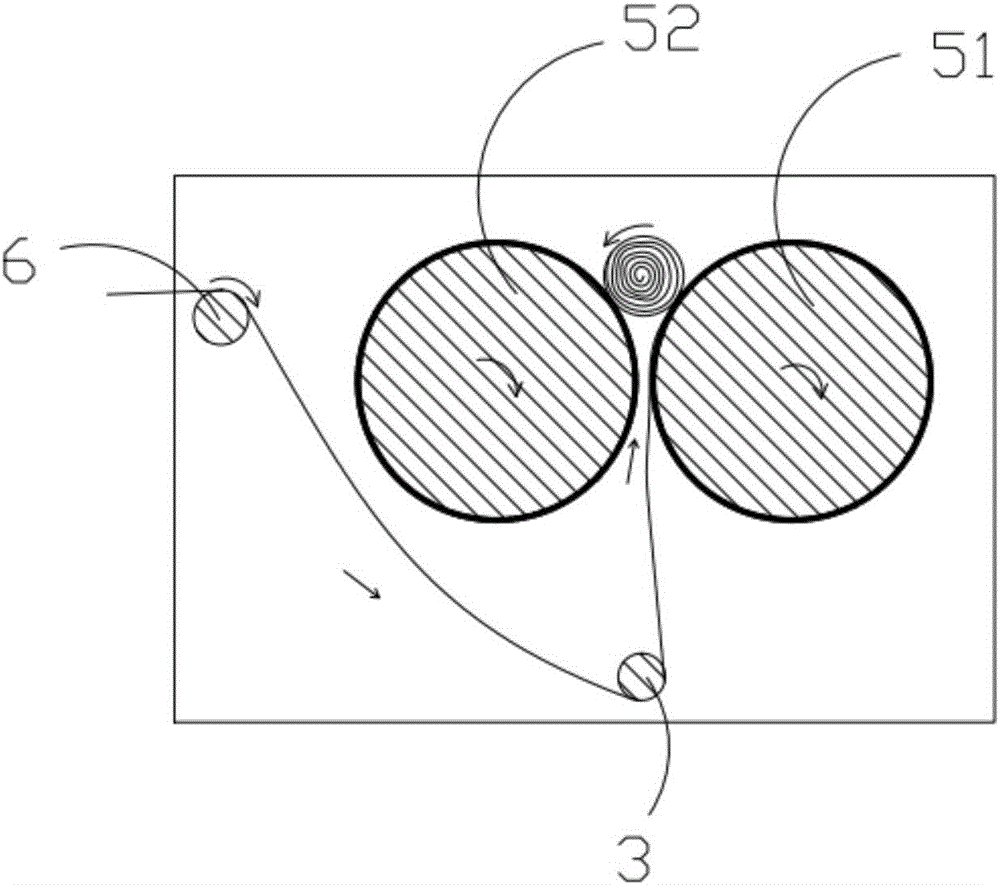

[0025] The invention discloses an embedded rolling device for a water jet loom, such as figure 1 and figure 2 As shown, it includes left frame 1 and right frame 2, guide roller 3, driving device 4 and cloth rolling device 5 located on the left and right sides; the two ends of guide roller 3 are respectively fixed with left frame 1 and right frame 2 connected, the guide roller 3 is located directly below the cloth rolling device 5, and is used to guide the cloth to change direction; the driving device 4 is connected to the cloth rolling device 5 and drives the cloth rolling shaft a51 and the cloth rolling shaft of the cloth rolling device 5 b52 rotate clockwise in the same direction or anticlockwise in the same direction.

[0026] In this embodiment, there is a gap 53 between the cloth roll shaft a51 and the cloth roll shaft b52 for the cloth to pass through. Compared with the prior art, the transverse dimension of the gap 53 has been adjusted so that the cloth does not need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com