A sample high-temperature shape tester and its imaging method

A tester and sample technology, applied in the field of detection and analysis, can solve problems such as low test efficiency and complex furnace tube design, and achieve the effects of improving sample test efficiency, improving energy utilization, and facilitating image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

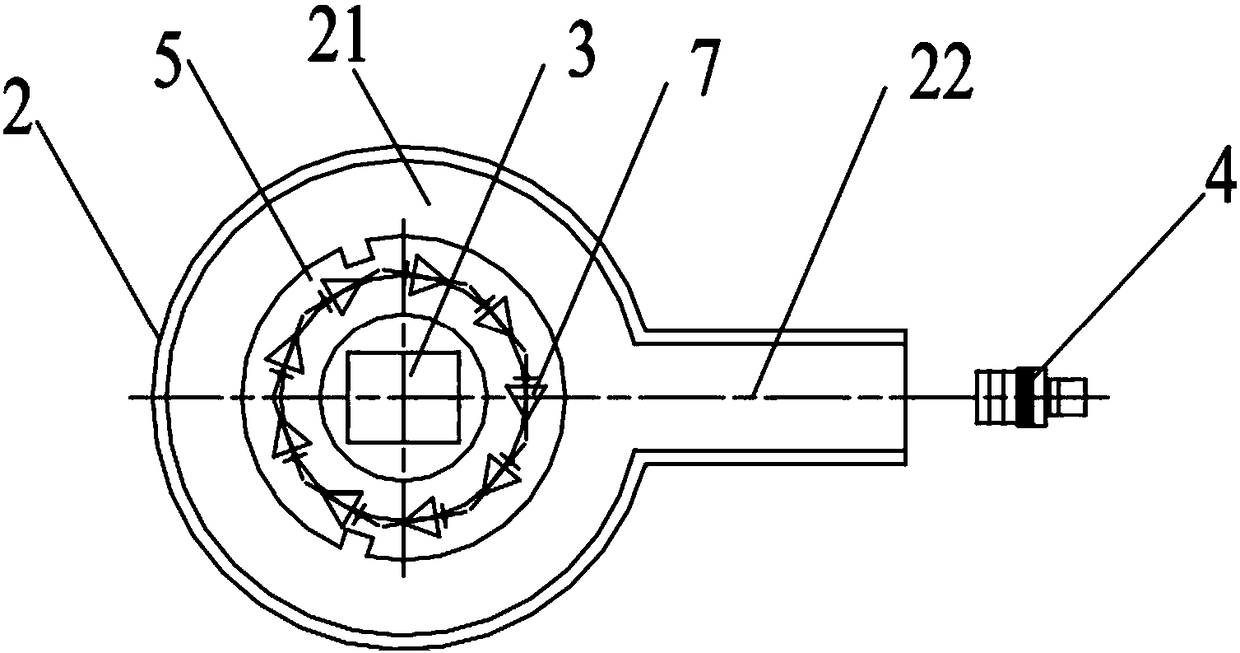

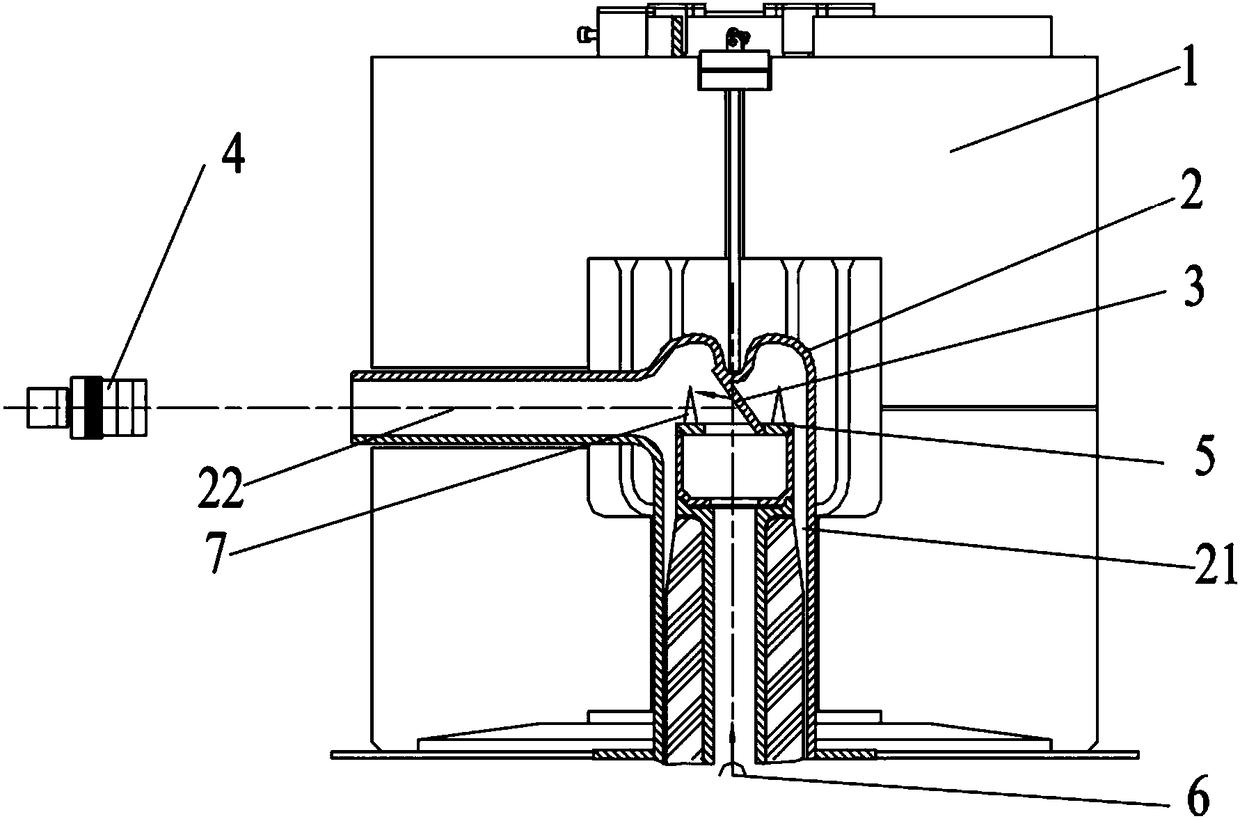

[0030] Such as Figure 2-Figure 4 As shown, a sample high-temperature form tester provided by the embodiment of the present invention can be used for the detection of the melting property of coal sample ash cones, the detection of the melting characteristics of biomass ash, the expansion coefficient, melting point, etc. of steel parts and the shape of samples at high temperatures. related testing. In this embodiment, the ash melting property used to measure coal sample ash cones is an example. The ash melting property tester includes a high-temperature furnace 1, a furnace tube 2, a background plate 3, an imaging assembly 4 and a disc-shaped supporting plate 5. The tube 2 is set in the high temperature furnace 1, the furnace tube 2 includes a sample placement cavity 21 and an imaging cavity 22 which is arranged on the side wall of the sample placement cavity 21 and communicates with the sample placement cavity 21, and the supporting plate 5 is arranged in the sample placement ...

Embodiment 2

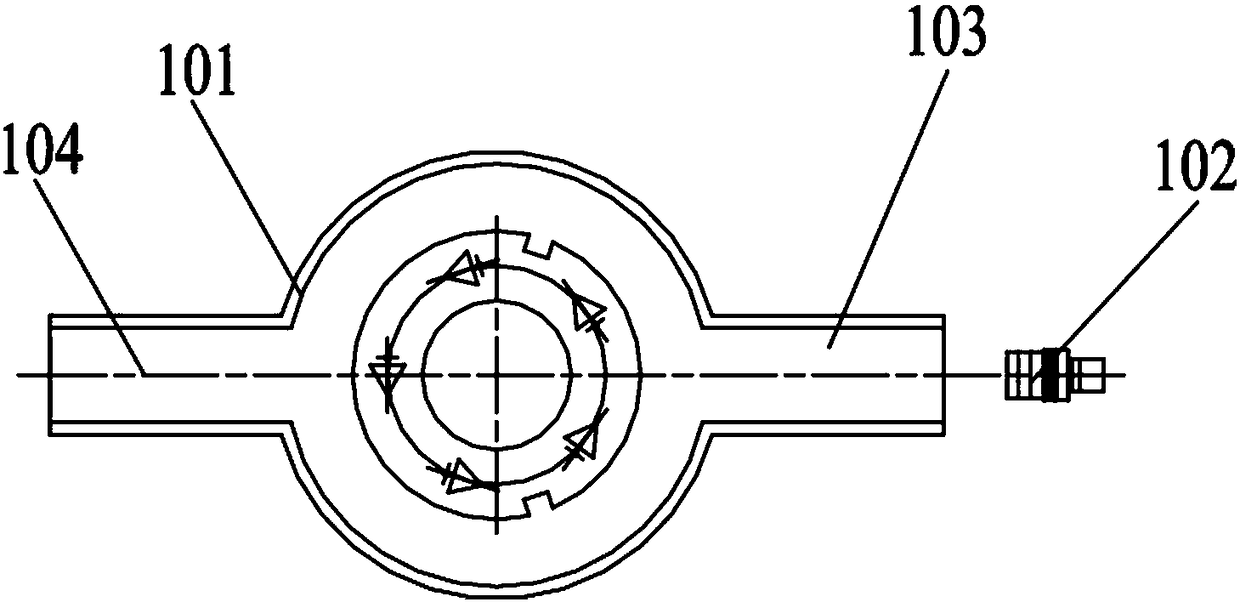

[0036] The technical content of the second embodiment that is the same as that of the first embodiment will not be described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment. The difference between the second embodiment and the first embodiment is that: Figure 5 and Figure 6 As shown, in this embodiment, the background plate 3 is a transmission element, the laser 6 is arranged outside the furnace tube 101 , and the emission end of the transmission element faces the ash cone 7 . When the light emitted by the laser 6 enters the background plate 3 , since the background plate 3 is a component with high transmittance, most of the energy can pass through the background plate 3 to form a bright background spot 61 on the background plate 3 .

Embodiment 3

[0038] The present embodiment 3 provides a kind of imaging method of above-mentioned ash fusion tester, comprises the following steps:

[0039] S1, when the gray cone 61 moves to the shooting range of the imaging assembly 4, the light spot 61 emitted by the laser 6 to the background plate 3 is displaced relative to the gray cone 7 until the movement track of the light spot 61 covers the entire gray cone 7 area; at the same time, the imaging component 4 performs continuous shooting.

[0040] Specifically, step S1 may be to move the spot 61 when the ash cone 7 is stationary: drive the ash awl 61 to rotate, and when the ash awl 61 moves into the shooting range of the imaging assembly 4, stop the movement of the ash awl 4 and drive the laser 6 The light spot 61 emitted to the background plate 3 moves, so that the movement track of the light spot 61 covers the area corresponding to the entire gray cone.

[0041] Step S1 can also be that the ash cone 7 moves when the light spot 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com