Water cooling annular hot cathode ion source neutralizer

A hot cathode ion source and ring-shaped technology, applied in the field of ion source technology, can solve the problems of reducing the stability of the neutralizer, affecting the use of the neutralizer, and polluting insulating ceramics, achieving cost reduction, improved service life, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is further described.

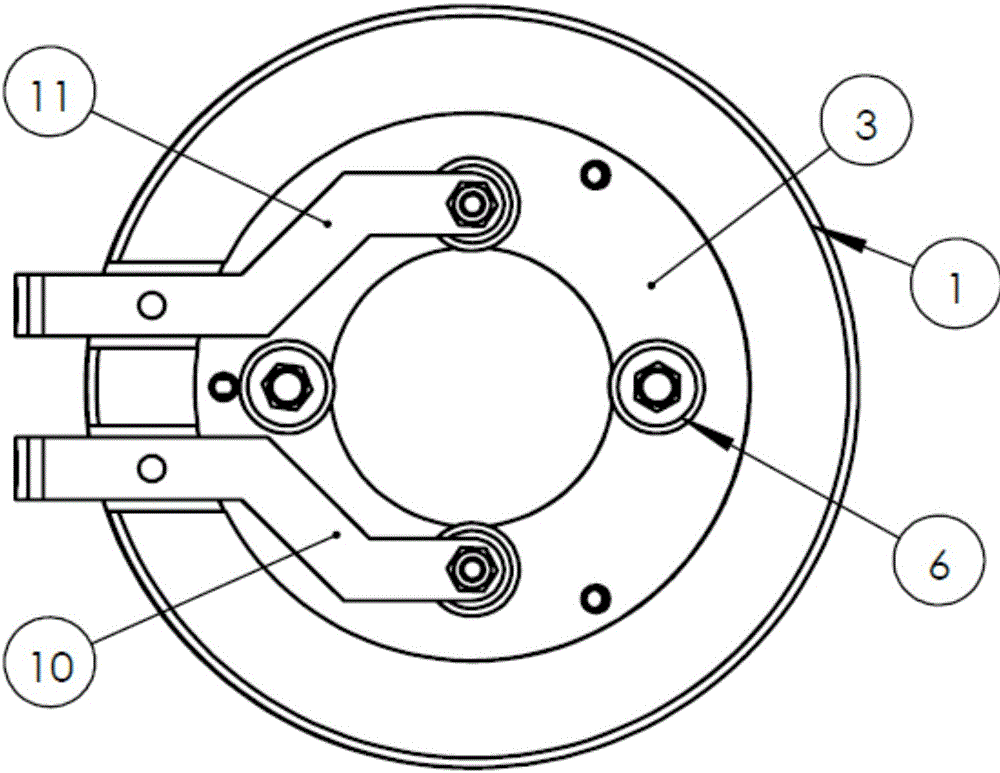

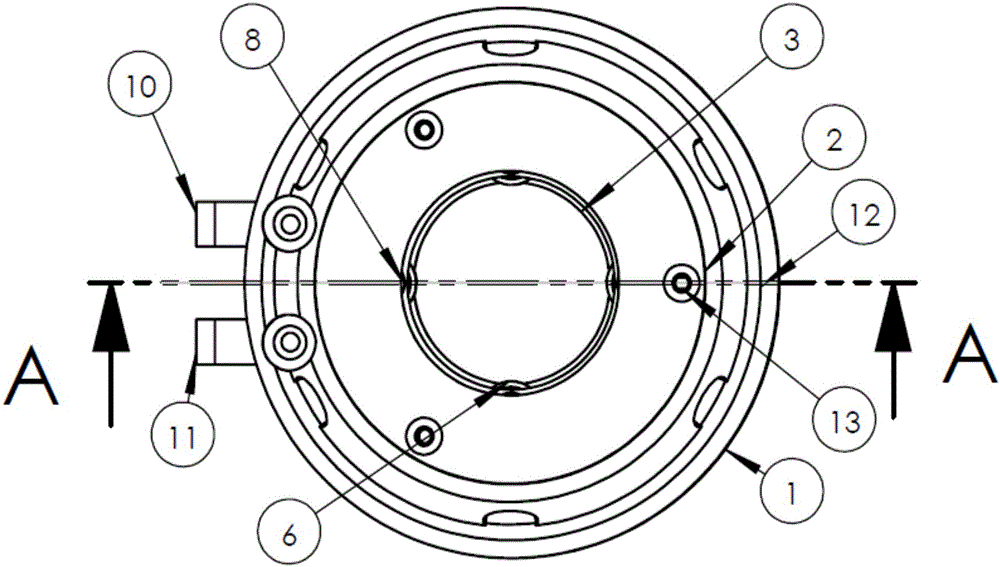

[0029] see figure 1 —7, water-cooled annular hot cathode ion source neutralizer, including main body 1, aperture 2, electrode fixing plate 3, tungsten wire electrode column 7, front side electrode 10 and rear side electrode 11, electrode fixing plate 3 is fixed on main body 1 On the top, the aperture 2 is fixed on the upper end of the main body 1, the tungsten wire electrode column 7 passes through the electrode fixing plate 3, and the front side electrode 10 and the rear side electrode 11 are fixed on the electrode fixing plate 3; it also includes a cooling water pipe 12 and a ring-shaped tungsten wire 13. The annular tungsten wire 13 is fixed on the main body 1, and the front electrode 10 and the rear electrode 11 are respectively set on the lower end of the tungsten wire electrode column 7; the cooling water pipe 12 is fixed on the concave semicircular groove outside the main body 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com