Tool magazine changer for machining centers

A technology of exchange device and machining center, which is used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the processing accuracy of parts products cannot meet the requirements, the overall accuracy of the tool arm type tool magazine is reduced, and the quality of processing is affected. And reliability and other issues, to avoid misuse and external force damage, simple structure, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

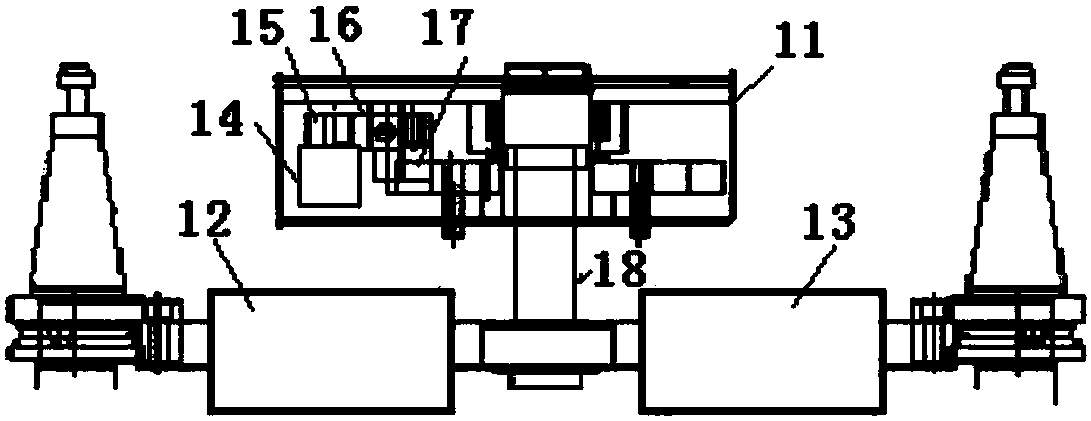

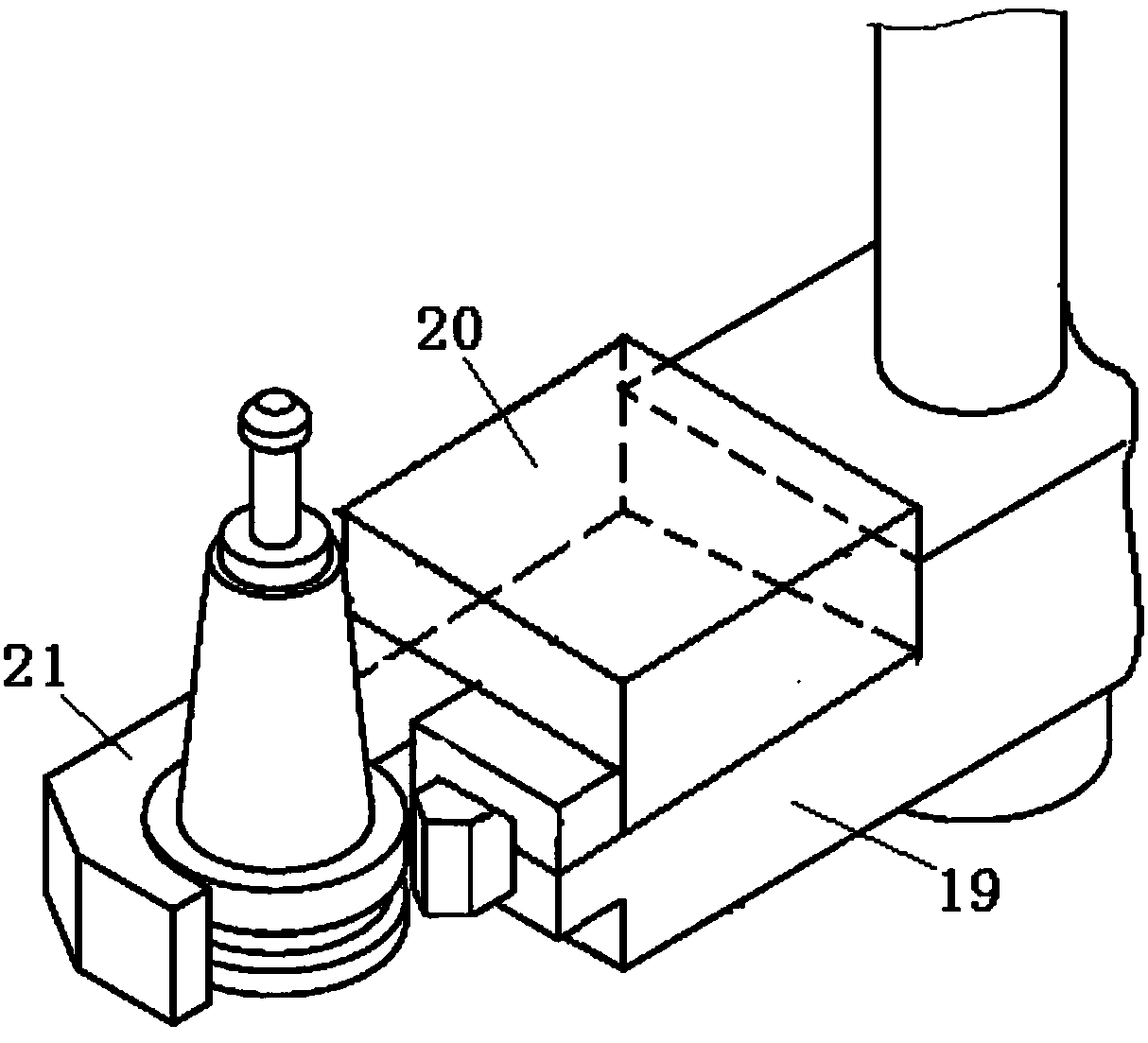

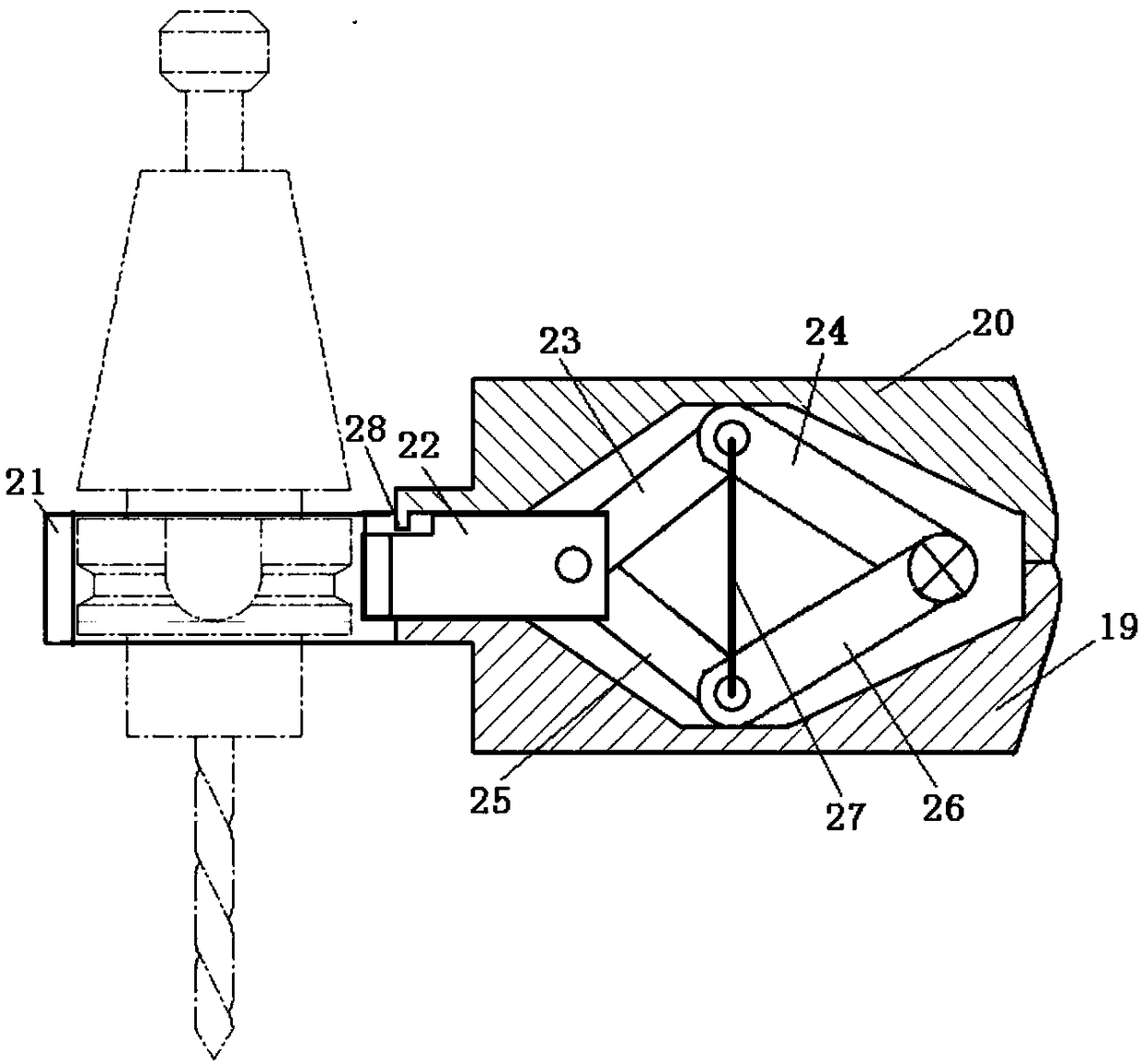

[0023] see Figure 1 to Figure 4 , shows the machining center tool magazine exchange device of the present invention, which can be applied to vertical or horizontal machining centers.

[0024] Among them, see figure 1 , the machining center tool magazine exchange device of the present invention includes a drive box 11 and an oil cylinder telescopic shaft 18, the oil cylinder telescopic shaft 18 extends outward from the drive box 11 and can perform telescopic operations, and its free end is provided with a clamping rod assembly, Thereby, it is driven by hydraulic oil to realize the outward extension and retraction of the telescoping shaft 18 of the oil cylinder and even the clamping rod assembly.

[0025] The drive box 11 is provided with a driving assembly that drives the telescopic shaft 18 of the oil cylinder to rotate, wherein the clamping rod assembly includes a first clamping rod 12 and a second clamping rod 13 that are designed symmetrically at 180 degrees. The driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com