Preparation method of fat emulsion, amino acid and glucose injection packed in three-cavity bag

A technology for glucose injection and fat emulsion, which is applied in the directions of emulsion delivery, medical preparations containing active ingredients, and pharmaceutical formulations, etc., can solve problems such as affecting the safety of clinical medication, increasing the size of fat emulsion particles, and affecting the stability of emulsions. , to achieve the effect of increasing drug safety, narrowing the distribution of milk particles, and reducing adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

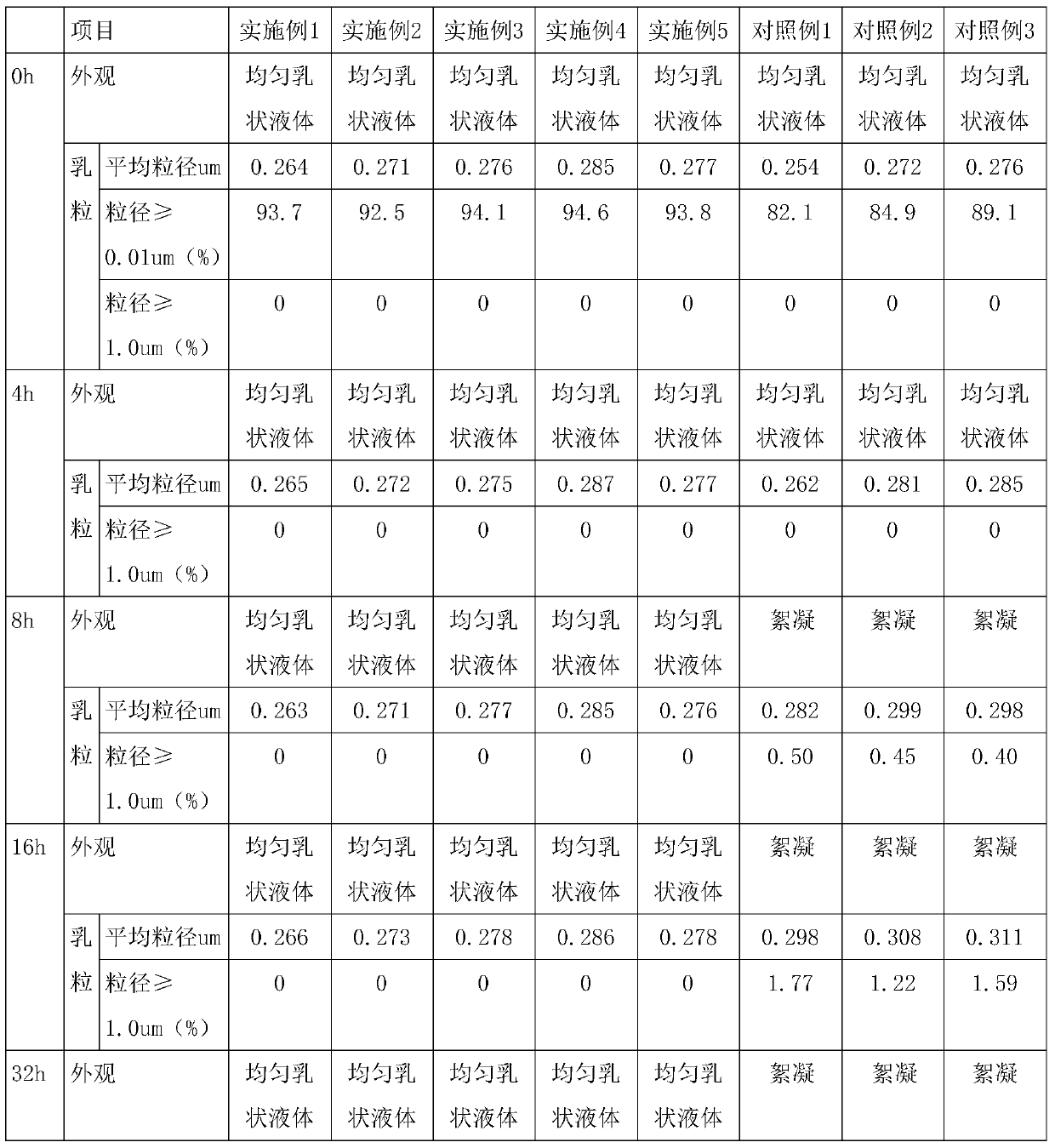

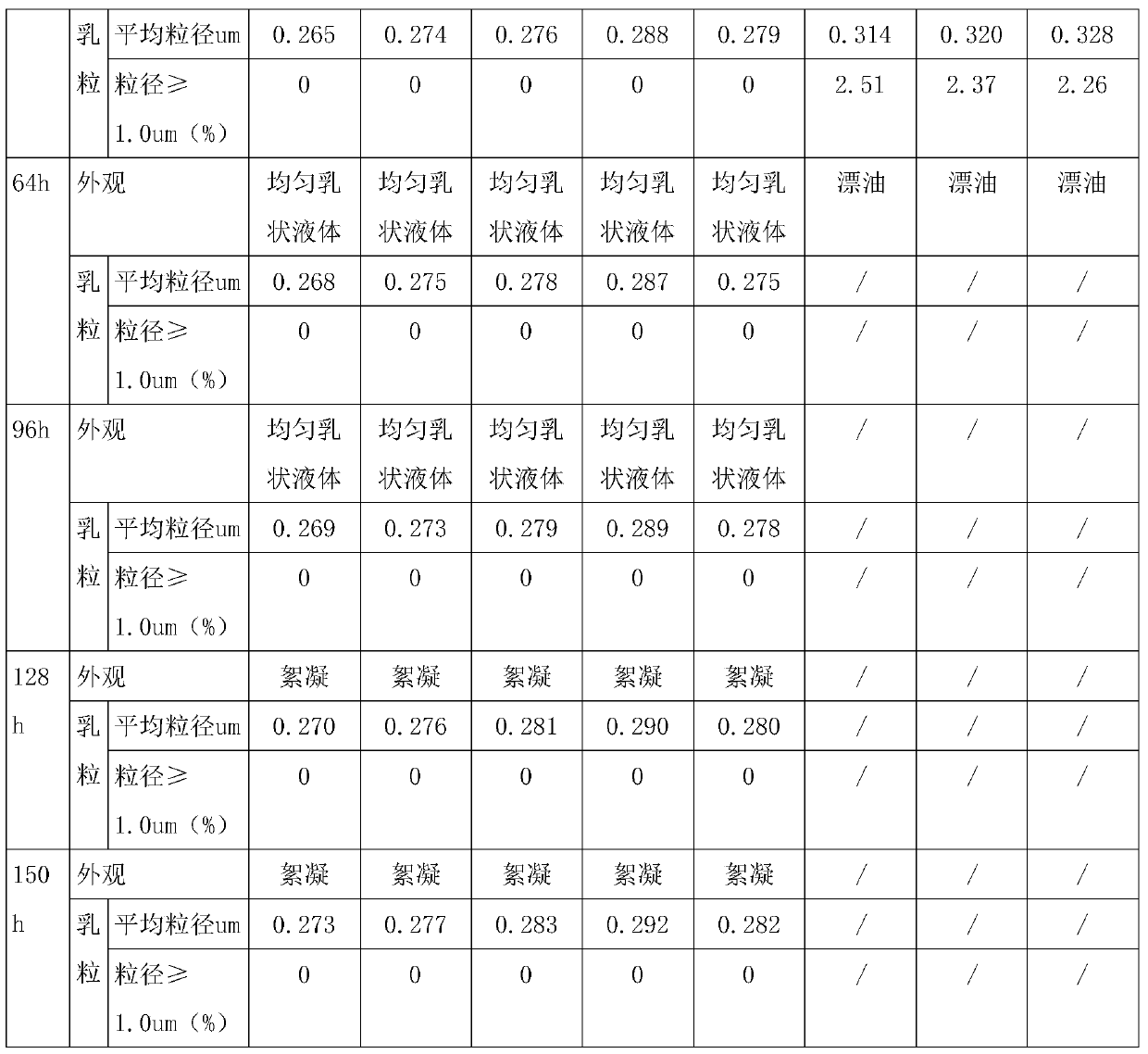

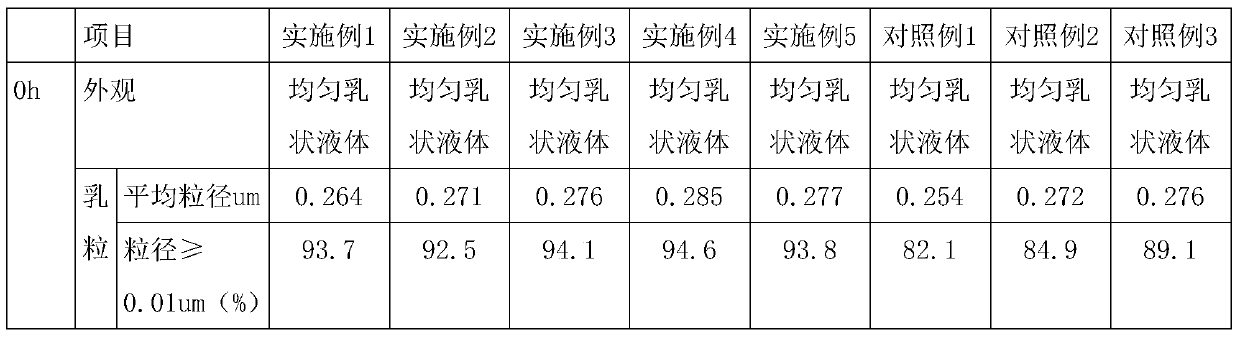

Examples

Embodiment 1

[0037] Preparation method of fat emulsion, amino acid and glucose injection packaged in three-chamber bag

[0038] (1) Dosing

[0039] a. Preparation of 10% Fat Emulsion Injection:

[0040] Each 1000ml fat emulsion injection contains 100g soybean oil, 6g lecithin, 12.5g glycerol, 0.15g sodium oleate, appropriate amount of sodium hydroxide and water for injection.

[0041] Oil phase preparation: take 100g soybean oil, heat to 70°C under nitrogen protection, add 6g lecithin, stir and disperse; water phase preparation: add 12.5g glycerol to 250ml water for injection, stir and dissolve and heat to 70°C , introduce nitrogen until the dissolved oxygen content of the water for injection reaches below 3mg / L; mix and stir the oil phase and the water phase, add water for injection to 400ml (40% of the preparation amount), and pass through a high-pressure homogenizer after stirring. The homogenization pressure is 650bar for the primary valve, 120bar for the secondary valve, homogenize ...

Embodiment 2

[0054] Preparation method of fat emulsion, amino acid and glucose injection packaged in three-chamber bag

[0055] (1) Dosing

[0056] a. Preparation of 10% Fat Emulsion Injection:

[0057] Each 1000ml fat emulsion injection contains 100g soybean oil, 12g lecithin, 13.0g glycerol, 0.5g sodium oleate, appropriate amount of sodium hydroxide and water for injection.

[0058] Oil phase preparation: take 100g soybean oil, heat to 90°C under nitrogen protection, add 12g lecithin, stir and disperse; water phase preparation: add 13.0g glycerol to 450ml water for injection, stir and dissolve and heat to 90°C , pass nitrogen until the dissolved oxygen content of water for injection reaches below 3mg / L; mix and stir the oil phase and water phase, add water for injection to 600ml (60% of the preparation amount), stir evenly and pass through a high-pressure homogenizer, The homogenization pressure is 650bar for the primary valve, 120bar for the secondary valve, homogenize 4 times, and th...

Embodiment 3

[0071] Preparation method of fat emulsion, amino acid and glucose injection packaged in three-chamber bag

[0072] (1) Dosing

[0073] a. Preparation of 10% Fat Emulsion Injection:

[0074] Each 1000ml fat emulsion injection contains 100g soybean oil, 6g lecithin, 12.5g glycerol, 0.15g sodium oleate, appropriate amount of sodium hydroxide and water for injection.

[0075] Oil phase preparation: take 100g soybean oil, heat it to 70°C under nitrogen protection; water phase preparation: take 12.5g glycerol and add it to 450ml water for injection, stir and dissolve, heat to 70°C, and pass nitrogen to the level of water for injection. Add 6g of lecithin to the dissolved oxygen below 3mg / L, stir and disperse; mix and stir the oil phase and the water phase, add water for injection to 600ml (60% of the prepared amount), stir evenly, and pass it through a high-pressure homogenizer. The homogenization pressure is 650bar for the primary valve, 120bar for the secondary valve, homogenize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com