Triangular alloy tool bit

An alloy knife and triangular technology, which is applied in metal processing equipment, drilling/drilling equipment, drilling tool accessories, etc., can solve the problems of reducing the efficiency of drill bit cutting operations, and achieve the effect of improving cutting efficiency and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

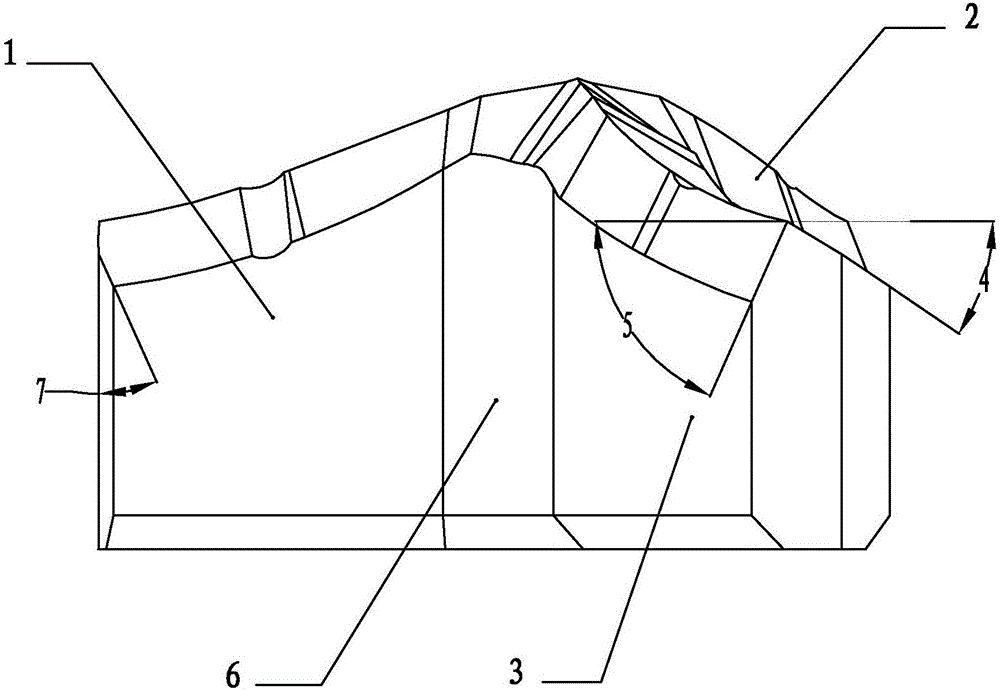

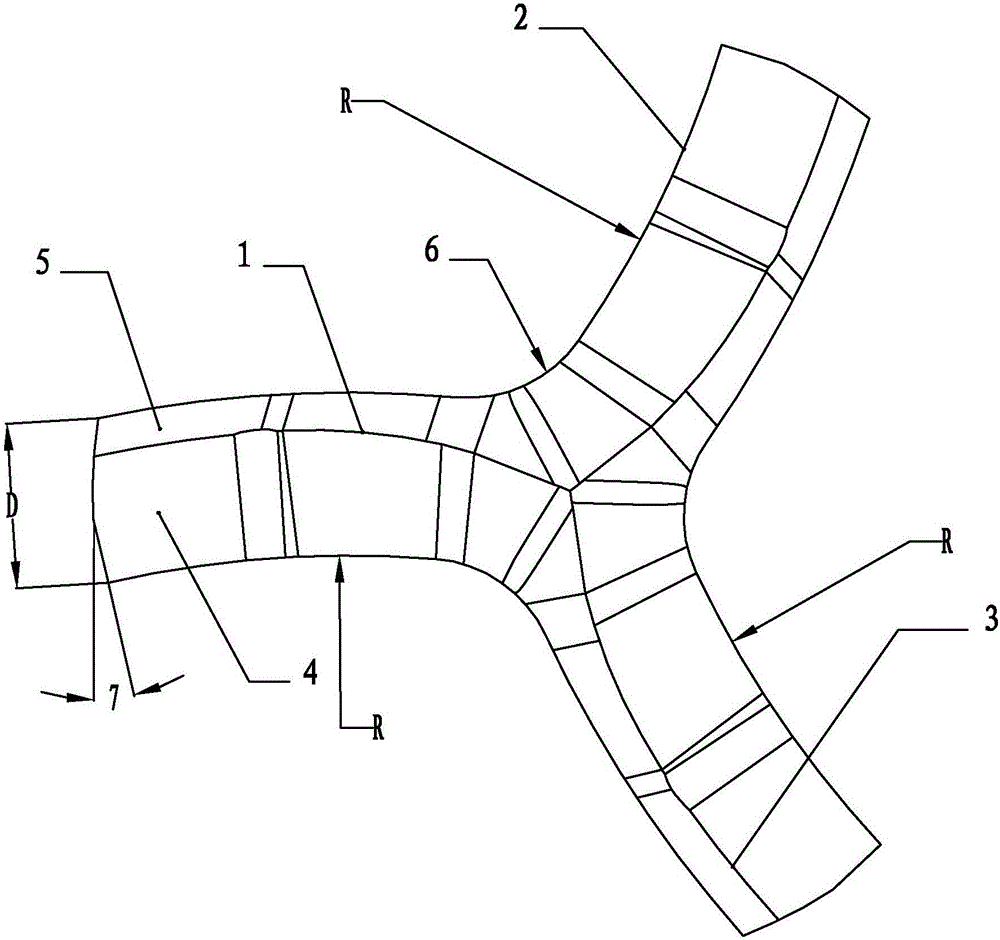

[0015] Such as Figure 1-2 As shown, the present invention is a triangular alloy cutter head. In order to improve the cutting efficiency of existing drill bits, the triangular alloy cutter head includes a first cutting edge 1, a second cutting edge 2 and a third cutting edge 3 and is in the form of The circular uniform arrangement is connected as a whole, the inside of the first cutting edge 1, the second cutting edge 2 and the third cutting edge 3 are higher than the outside so that the first cutting edge 1, the second cutting edge 2 and the third cutting edge The upper ends of the blades 3 are respectively inclined; by setting the first cutting edge 1, the second cutting edge 2 and the third cutting edge 3, when the drill bit is in operation, the electric drill can drive the drill bit to rotate once, which can be correspondingly compared with the existing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com