Automatic cutting robot for PVC pipe

An automatic cutting and PVC pipe technology, which is applied in metal processing and other directions, can solve the problems of inaccurate length, difficult cutting of the incision, and difficult docking, so as to improve the quality of the incision and increase the cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

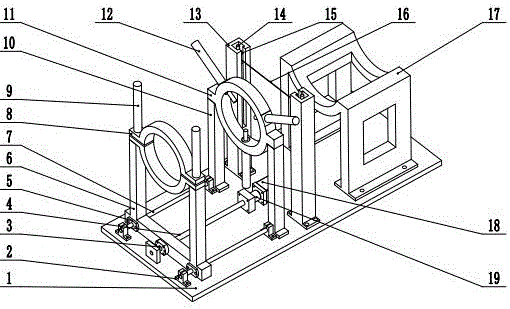

[0009] Such as figure 1 As shown, a PVC pipe automatic cutting robot includes a base 1, four vertical optical shaft seats 2, a screw nut 3, a ball screw 4, two linear bearings 5, a lower part of a moving bracket 6, and two optical shafts 7 , the upper part of the moving bracket 8, two first linear motors 9, two fixed brackets 10, pipe clamp brackets 11, three second linear motors 12, two lifting brackets 13, two pairs of T-shaped lead screws 14, two Slider 15, electric heating wire 16, stinger frame 17, stepper motor 18 and shaft coupling 19, it is characterized in that: described vertical optical shaft seat 2 is fixedly installed on base 1 by bolt; Described optical shaft 7 is fixed on the vertical optical shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com