Hot-melt adhesive film composite splicing veneer and plywood production process using it

A hot-melt adhesive film and production process technology, which is applied in the joining of wooden veneers, manufacturing tools, layered products, etc., can solve the problems of high labor intensity, backward production technology, and many people, and improve the production process. , the effect of improving quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

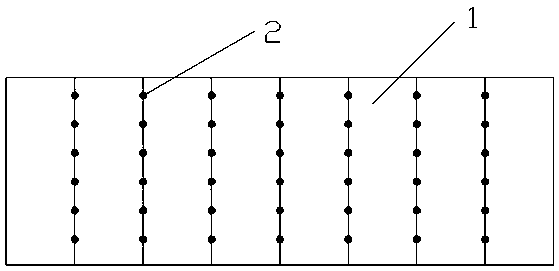

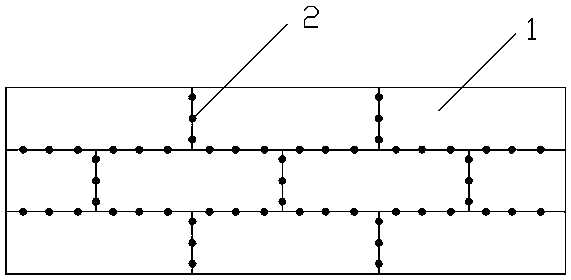

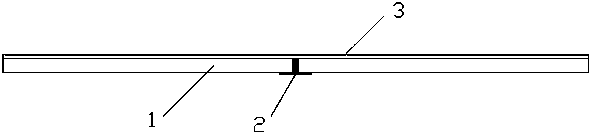

[0023] Such as Figure 1~7 As shown, a hot-melt adhesive film composite splicing veneer includes a plurality of veneers 1 spliced together, and the seams between two spliced adjacent veneers 1 are bonded to each other by multi-point hot-melt adhesive 2 Together, it also includes a layer of hot-melt adhesive film 3 bonded to one side of all the veneers. The hot-melt adhesive film 11 is made of formaldehyde-free film-like wood adhesive. Cut out the required specifications, and then make plywood by superimposing hot-pressing and cold-pressing on the multi-layer hot-melt adhesive film composite splicing veneer, which can greatly improve the processing efficiency, and can avoid the serious influence of excessive splicing seams and overlapping in the traditional process on plywood The downside of quality.

[0024] In this embodiment, the veneers are spliced horizontally or spliced vertically according to the direction of the wood grain.

[0025] Such as Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com