Core mold vibration process flexible joint steel bell and spigot jacking pipe mold

A flexible joint and socket forming technology, applied in the direction of molds, etc., can solve the problems of easy inclination error, sewage, soil infiltration, inability to ensure the concentricity of the socket and socket, and achieve the effect of good forming effect and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

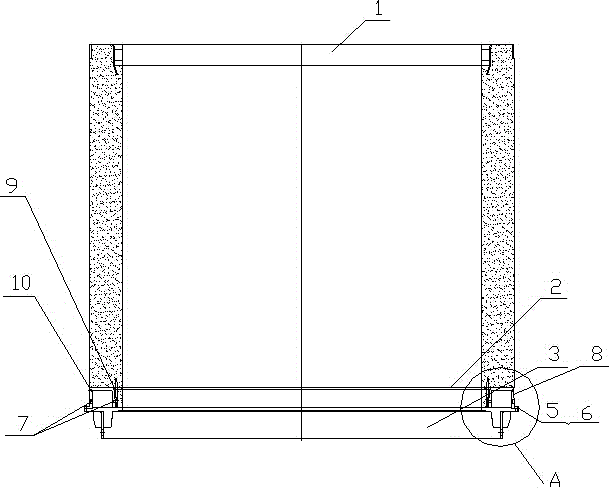

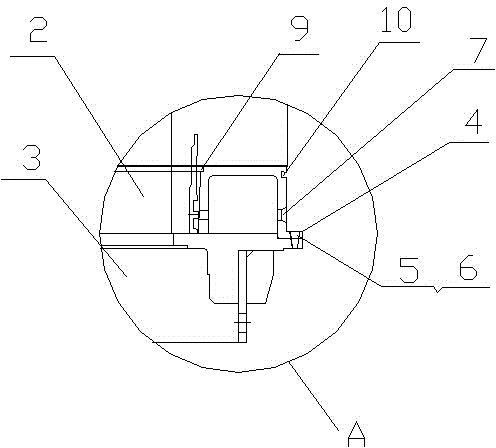

[0012] Such as figure 1 As shown, this core mold vibration process flexible joint steel socket jacking pipe forming mold includes socket forming ring 1, socket forming ring 2, socket chassis 3, socket forming ring 2 and socket chassis 3 detachably connected, socket The outer edges of the forming ring 2 and the socket chassis 3 are respectively provided with a circle of outward flange edges 4, and at least eight uniformly distributed taper pin holes 5 are provided on the flange edges 4 of the socket forming ring 2 and the socket chassis 3, and the socket is formed The ring 2 corresponds to the taper pin holes 5 of the socket chassis 3 one-to-one, and each group of corresponding taper pin holes 5 is provided with a taper pin 6, and the end surface of the taper pin 6 does not protrude from the free end surface of the flange 4; ring 2 is formed in the socket Three radial pin holes 7 are provided on the upper part, and the three radial pin holes 7 respectively correspond to the press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap