Fireproof coating for tunnel and preparation method thereof

A technology for fire-resistant coatings and tunnels, applied in fire-resistant coatings, cement coatings, coatings, etc., can solve the problems of high traffic density, difficulty in evacuation and rescue, and easy to burn and collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

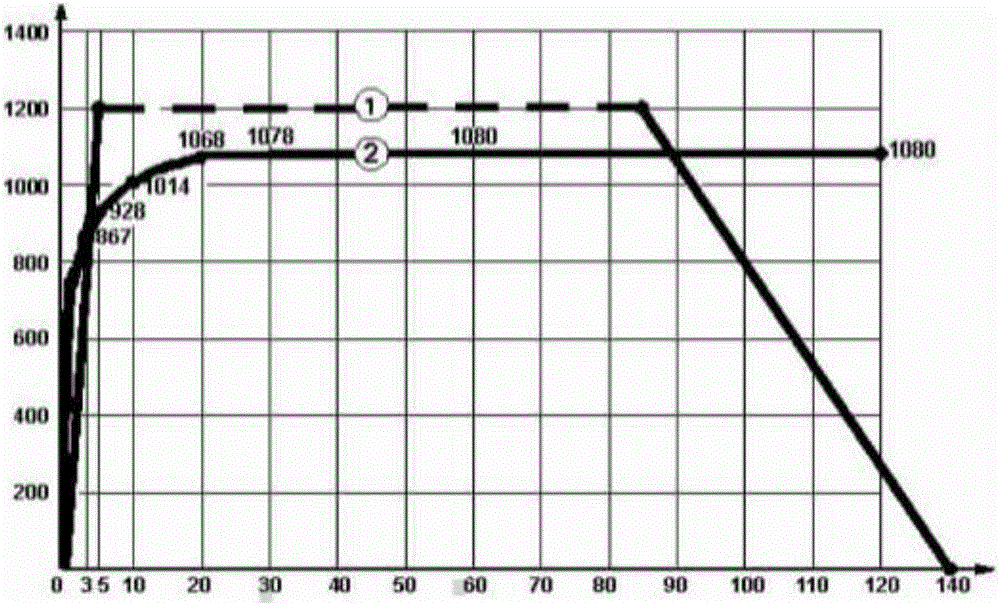

Image

Examples

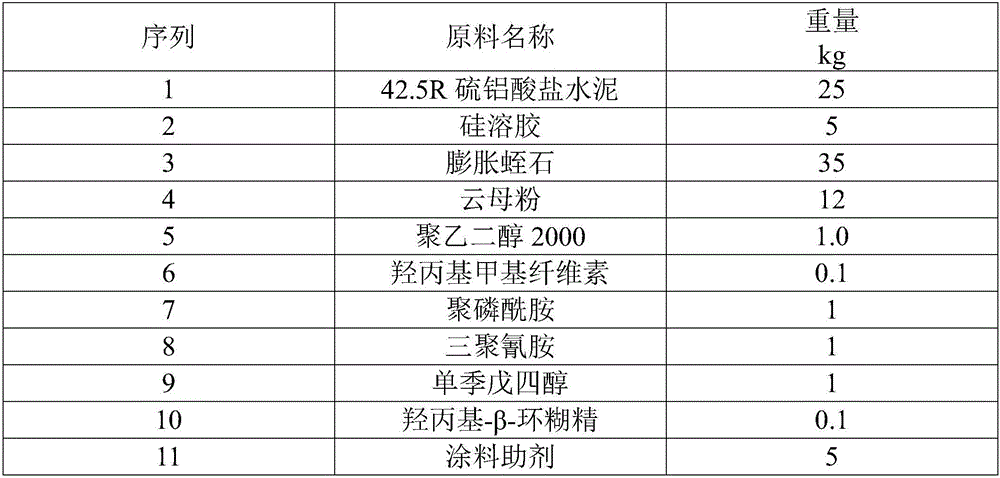

Embodiment 1

[0030] Table 1 Raw material ratio

[0031]

[0032] The coating preparation method is:

[0033] (1) sieve the expanded vermiculite 1-3mm to remove coarse particles;

[0034] (2) Add sulfoaluminate cement, silica gel powder, mica powder into a dry powder mixer, gradually add polyethylene glycol 2000 during stirring, then add additives, and finally add other raw materials, mix evenly, and obtain a coating.

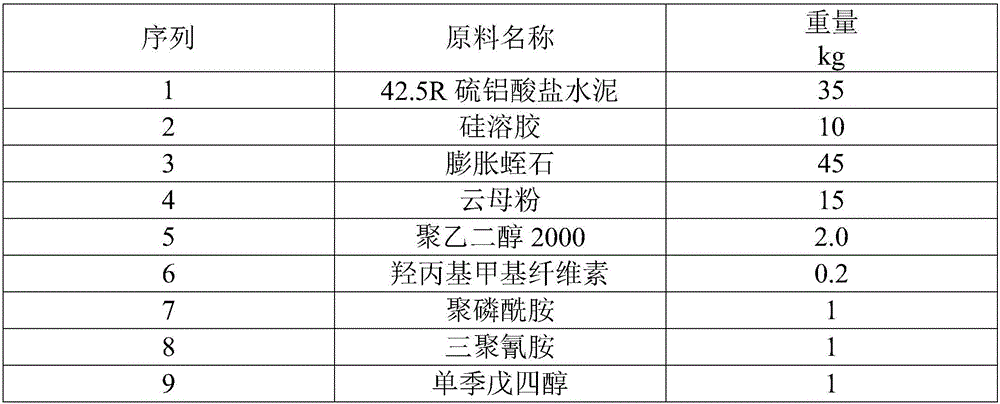

Embodiment 2

[0036] Table 2 Raw material ratio

[0037]

[0038]

[0039] The coating preparation method is:

[0040] (1) sieve the expanded vermiculite 1-3mm to remove coarse particles;

[0041] (2) Add sulfoaluminate cement, silica gel powder, mica powder into a dry powder mixer, gradually add polyethylene glycol 2000 during stirring, then add additives, and finally add other raw materials, mix evenly, and obtain a coating.

Embodiment 3

[0043] Table 3 Raw material ratio

[0044]

[0045] The coating preparation method is:

[0046] (1) sieve the expanded vermiculite 1-3mm to remove coarse particles;

[0047] (2) Add sulfoaluminate cement, silica gel powder, mica powder into a dry powder mixer, gradually add polyethylene glycol 2000 during stirring, then add additives, and finally add other raw materials, mix evenly, and obtain a coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com