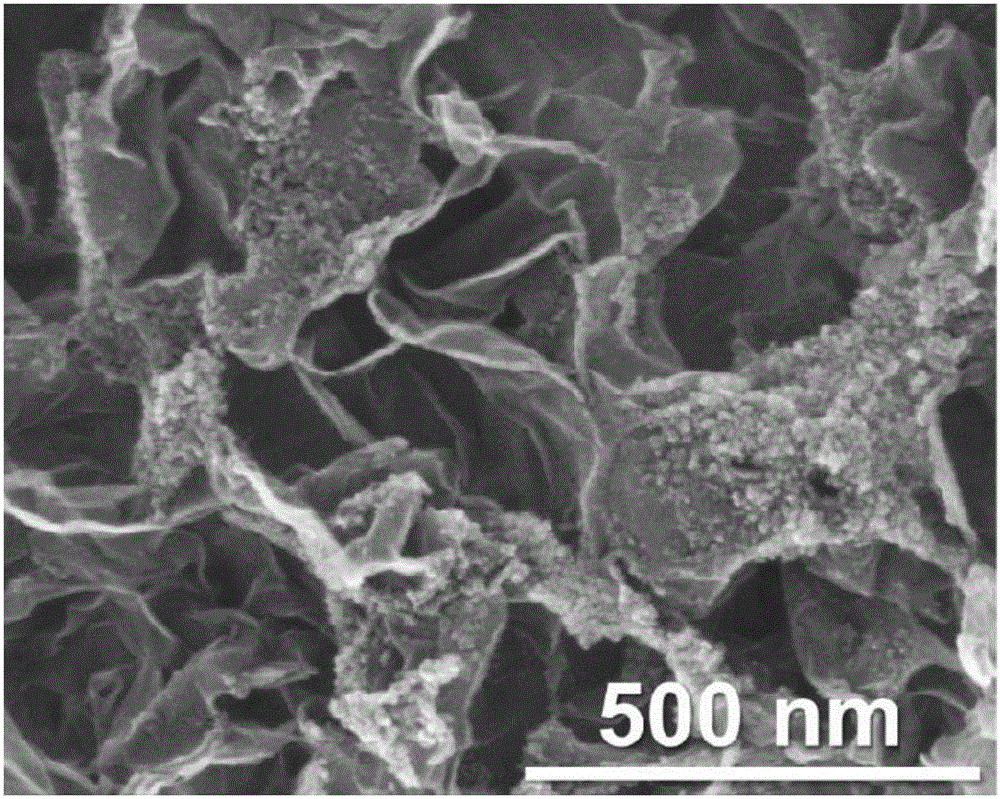

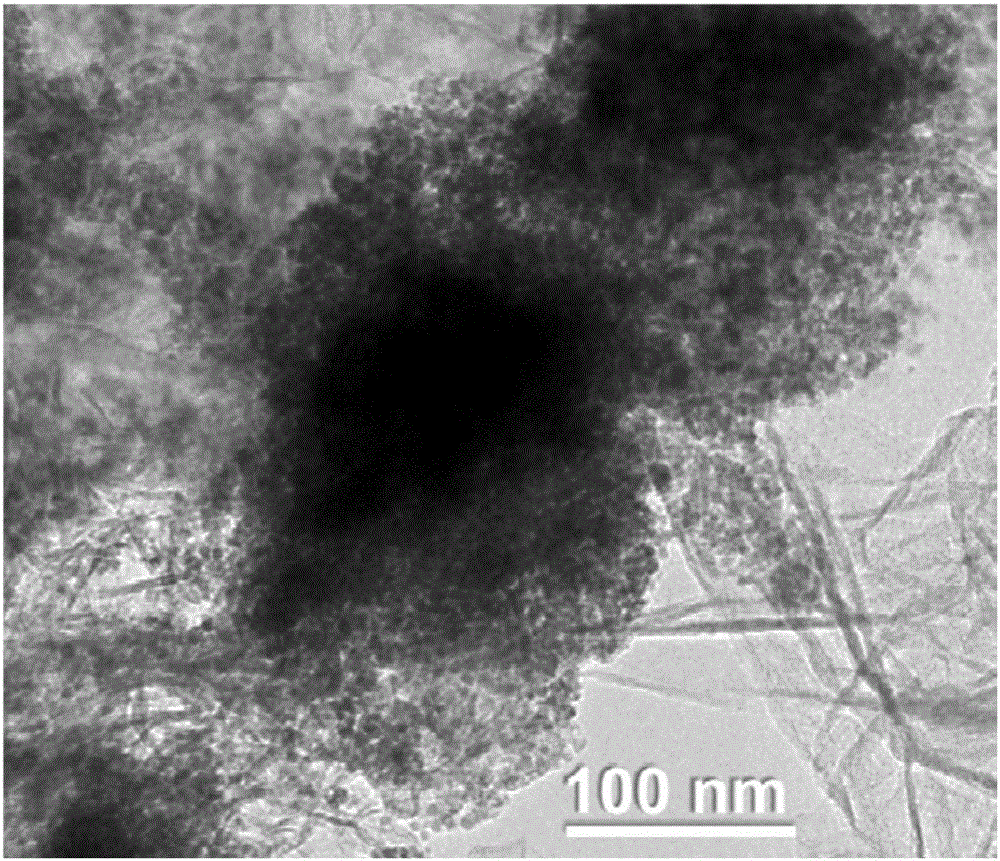

Preparation method of graphene half-coated tin dioxide nanometer particle cluster composite material

A technology of tin dioxide and nanoparticles, applied in the direction of secondary batteries, electrochemical generators, electrical components, etc., can solve problems such as unsatisfactory performance and capacity drop, achieve effective and rapid embedding and extraction, slow down loss, improve The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a graphene half-coated tin dioxide nanoparticle cluster composite material, comprising the following steps:

[0035] The 1st (1) step, under stirring state, surfactant is dissolved in tin dioxide hydrosol, concrete steps are as follows: the hydrosol containing the tin dioxide nanoparticle that diameter is 2nm is diluted to 20g / L, gets 20mL, 0.5 g of surfactant P123 was added thereto under stirring, and stirred to dissolve it.

[0036] In the (2) step, add the aqueous dispersion of carbohydrates and small-diameter graphene oxide, and continue to stir to obtain a uniform precursor dispersion. The specific steps are as follows: add 2 mL of glucose solution with a concentration of 200 g / L, and then add 4 mL of aqueous dispersion of small-diameter graphene oxide (diameter of small-diameter graphene oxide is 200-1000 nm) with a concentration of 10 g / L, and continuously stirred for 2 h.

[0037] In step (3), the precursor dispersion obtained in the pre...

Embodiment 2

[0041] Graphene half-coated tin dioxide nanoparticle cluster composite material preparation method, comprising the following steps:

[0042] The 1st (1) step, under stirring state, surfactant is dissolved in tin dioxide hydrosol, concrete steps are as follows: the hydrosol containing the tin dioxide nanoparticle that diameter is 5nm is diluted to 1g / L, gets 400mL, Add 5g of surfactant polyacrylamide therein under stirring state, stir to make it dissolve.

[0043] In the (2) step, add the aqueous dispersion of carbohydrates and small-diameter graphene oxide, and continue to stir to obtain a uniform precursor dispersion. The specific steps are as follows: add 500 mL of sodium alginate solution with a concentration of 2 g / L, Subsequently, 100 mL of an aqueous dispersion of small-diameter graphene oxide (diameter of small-diameter graphene oxide is 200-1000 nm) with a concentration of 0.2 g / L was added, and stirring was continued for 0.5 h.

[0044] In step (3), the precursor dis...

Embodiment 3

[0047] A kind of preparation method of the lithium-ion battery / sodium-ion battery electrode material of the tin dioxide nanoparticle cluster lithium-ion battery / sodium-ion battery half-covered by graphene, comprises the following steps:

[0048] The 1st (1) step, under stirring state, surfactant is dissolved in tin dioxide hydrosol, concrete steps are as follows: the hydrosol containing the tin dioxide nanoparticle that diameter is 10nm is diluted to 50g / L, gets 8mL, Add one or more of P123, F127, sodium dodecylsulfonate, sodium dodecylbenzenesulfonate, polyacrylamide, stearate or fatty alcohol sulfate to it under stirring state. EXAMPLES 1g of surfactant F127 was added and stirred to dissolve it.

[0049] In the (2) step, add the aqueous dispersion of carbohydrates and small-diameter graphene oxide, and continue to stir to obtain a uniform precursor dispersion. The specific steps are as follows: adding 50 mL of chitosan solution with a concentration of 20 g / L, Subsequently, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com