Preparation method of catalyst carrier for preparing natural gas from coke-oven gas

A catalyst carrier and natural gas technology, applied in the field of catalysis, can solve the problems of difficult operation, high reaction space velocity, high pressure, poor high temperature resistance, etc., and achieve the effects of good hydrothermal stability and less carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

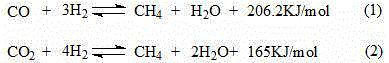

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: (1) mix 800g of magnesium nitrate with water; (2) under stirring, add the prepared sodium carbonate solution into the solution formed in step 1 for neutralization reaction, the reaction temperature is 60°C, and the pH value at the end of the reaction is controlled at 8.0; (3) Wash the precipitate obtained in step 2 with deionized water; (4) add 90g of calcium oxide, 30g of magnesium oxide and 300g of γ-Al to the washed qualified precipitate obtained in step 3 2 o 3 Mix and beat together; (5) The material is filtered, dried, and roasted at 550°C for 2 hours; (6) Add 3% methyl cellulose for granulation; (7) Press into tablets; Calcined for 2 hours to obtain the methane synthesis catalyst carrier I.

Embodiment 2

[0020] Example 2: (1) Mix 600g of magnesium sulfate with water; (2) Under stirring, add the prepared sodium bicarbonate solution into the solution formed in step 1 for neutralization reaction, the reaction temperature is 90°C, and the pH value at the end of the reaction is controlled At 8.0; (3) Wash the precipitate obtained in step 2 with deionized water; (4) add 90g of calcium oxide, 90g of magnesium oxide, 150g of lanthanum nitrate and 350g of γ-Al to the washed precipitate obtained in step 3 2 o 3 Mixing and beating together; (5) The material is filtered, dried, and roasted at 450°C for 2 hours; (6) Add 5% cellulose acetate for granulation; (7) Press into tablets; (8) Roast at 900°C 2h to obtain the methane synthesis catalyst carrier II.

Embodiment 3

[0021] Example 3: (1) mix 600g of magnesium sulfate with water; (2) under stirring, add the prepared sodium carbonate solution into the solution formed in step 1 for neutralization reaction, the reaction temperature is 80°C, and the pH value at the end of the reaction is controlled at 7.5; (3) Wash the precipitate obtained in step 2 with deionized water; (4) add 150g of barium oxide, 90g of magnesium oxide, 150g of cerium nitrate and 350g of γ-Al to the washed qualified precipitate obtained in step 3 2 o 3 Mixing and beating together; (5) The material is then filtered, dried, and roasted at 500°C for 2 hours; (6) Add 4% nitrocellulose for granulation; (7) Press into tablets; (8) Roast at 900°C 2h to obtain the methane synthesis catalyst carrier III.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap