Method for plasma oxygen-carbon co-permeation of titanium-based or zirconium-based metal surface

A technology of plasma oxygen and base metal, which is applied in metal material coating technology, air transportation, coating, etc., can solve the problems of high temperature and long treatment time of oxygen carburizing, and achieve low treatment temperature, fast penetration speed, The effect of small workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

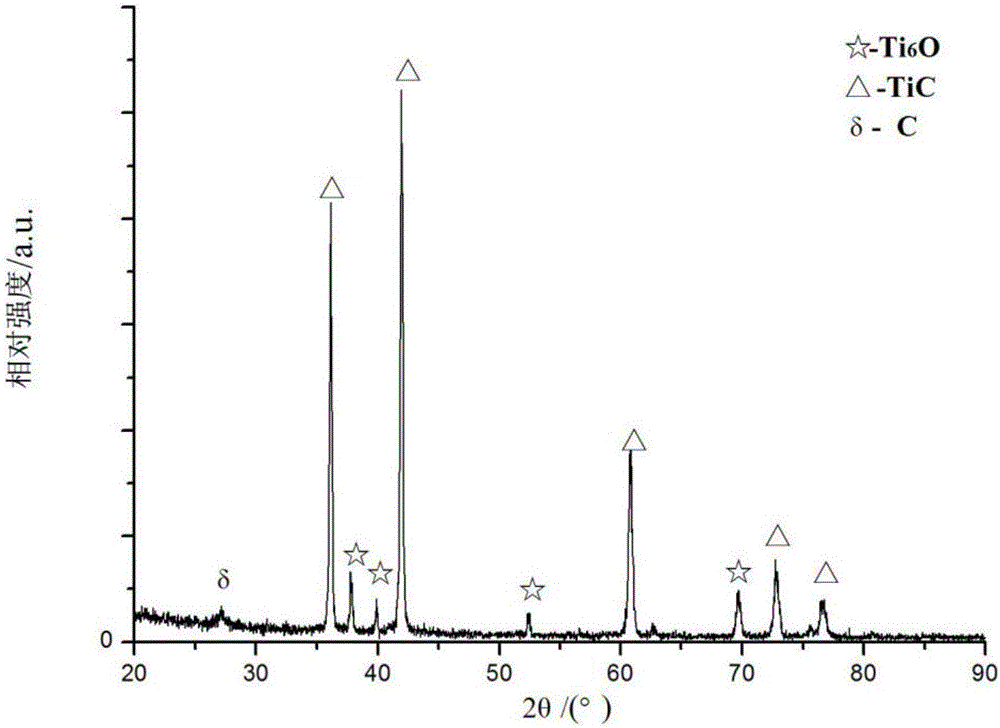

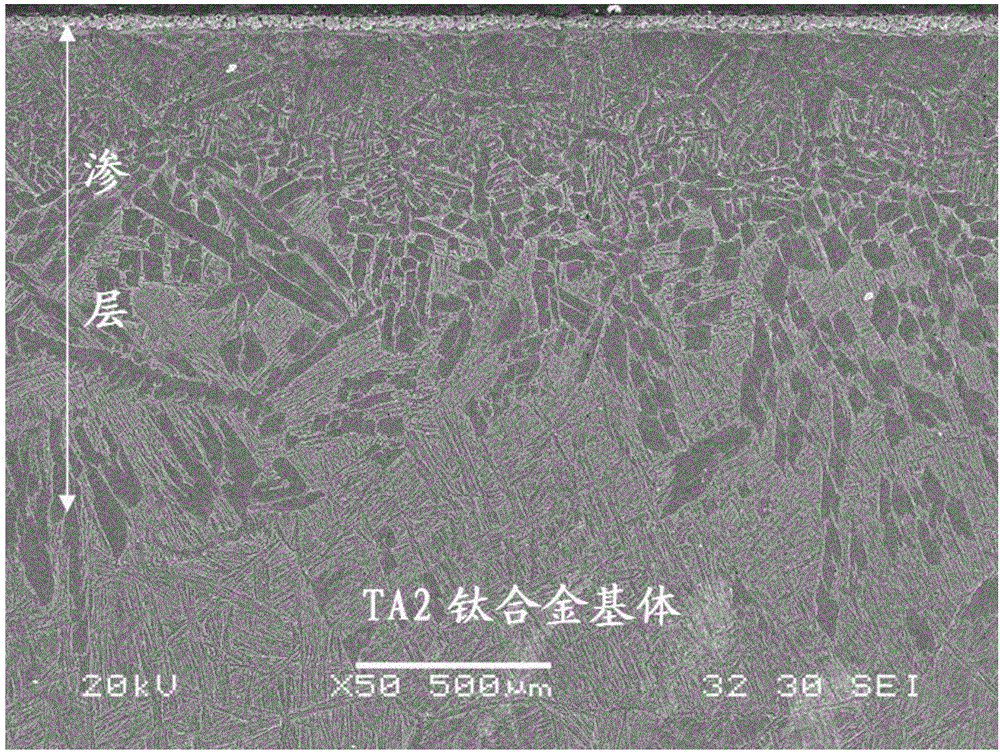

[0041] Example 1

[0042]The method for plasma oxycarburizing on the surface of the TA2 titanium alloy of the present embodiment includes the following steps:

[0043] Step 1. Pretreatment of pickling, mechanical polishing, degreasing cleaning and dehydration drying is performed on the α-type TA2 titanium alloy workpiece;

[0044] Step 2. Place the pretreated TA2 titanium alloy workpiece described in Step 1 in an ion chemical heat treatment furnace, and pre-evacuated to 1×10 -3 Pa, then pass through Ar and CO at the same time 2 Gas, control Ar and CO 2 The flow ratio is 1:4;

[0045] Step 3. When the vacuum degree in the ion chemical heat treatment furnace in Step 2 reaches 100Pa, load the TA2 titanium alloy workpiece with a negative bias voltage of 300V to generate a glow discharge, clean the workpiece with glow plasma for 10min, and then increase Negative bias voltage to 800V, heat the TA2 titanium alloy workpiece, make the TA2 titanium alloy workpiece heat up to 900 ℃, ...

Example Embodiment

[0048] Example 2

[0049] The method for surface plasma oxycarburization of TA12 titanium alloy (α type) of the present embodiment includes the following steps:

[0050] Step 1. Pretreatment of pickling, mechanical polishing, degreasing cleaning, dehydration and drying is performed on the α-type titanium alloy TA12 titanium alloy workpiece;

[0051] Step 2. Place the pretreated TA12 titanium alloy workpiece in step 1 in an ion chemical heat treatment furnace, and pre-evacuated to 9×10 -3 Pa, pass through Ar and CO, respectively 2 Gas, control Ar and CO 2 The flow ratio is 1:10, and the vacuum degree is adjusted to 1Pa;

[0052] Step 3. When the vacuum degree in the ion chemical heat treatment furnace in step 2 reaches 1Pa, load the TA12 titanium alloy workpiece with a negative bias voltage of 200V to generate a glow discharge, and use the glow plasma to clean the TA12 titanium alloy workpiece for 30min, Then increase the negative bias to 1200V, heat the TA12 titanium alloy...

Example Embodiment

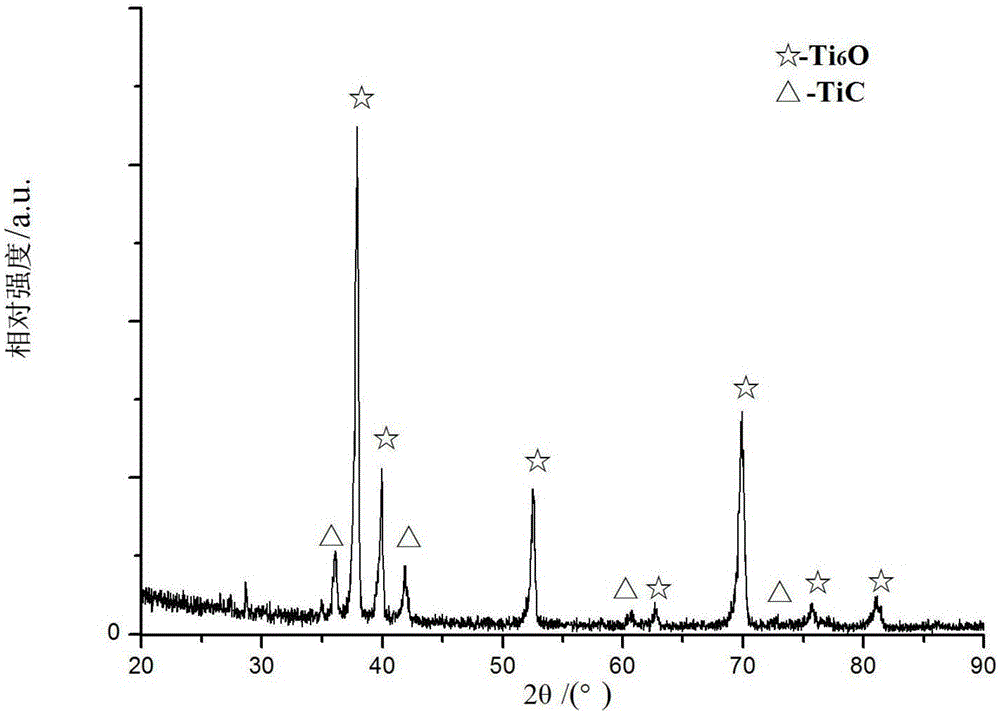

[0054] Example 3

[0055] The method for plasma oxycarburizing of the α+β type TC4 titanium alloy workpiece of the present embodiment comprises the following steps:

[0056] Step 1, carry out the pretreatment of pickling, mechanical polishing, degreasing cleaning, dehydration and drying on the TC4 titanium alloy workpiece;

[0057] Step 2, place the pretreated TC4 titanium alloy workpiece in the ion chemical heat treatment furnace in the step 1, and pre-evacuated to 4×10 -3 Pa, pass through Ar and CO, respectively 2 Gas, control Ar and CO 2 The flow ratio is 10:1;

[0058] Step 3, when the vacuum degree in the ion chemical heat treatment furnace in step 2 reaches 600Pa, load the TC4 titanium alloy workpiece with a negative bias voltage of 500V to generate a glow discharge, and use the glow plasma to clean the TC4 titanium alloy workpiece for 200min, Then increase the negative bias to 800V, heat the TC4 titanium alloy workpiece to 930°C, and undergo 5h ion oxycarburizing tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap