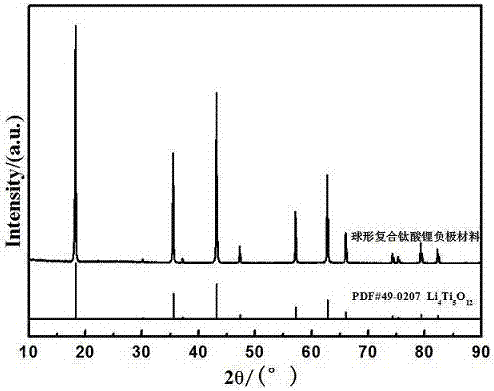

A kind of spherical lithium titanate composite negative electrode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of increased battery processing difficulty, cycle performance attenuation, difficult dispersion, etc., to achieve excellent electrochemical performance, processing performance suppression, easy to use scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

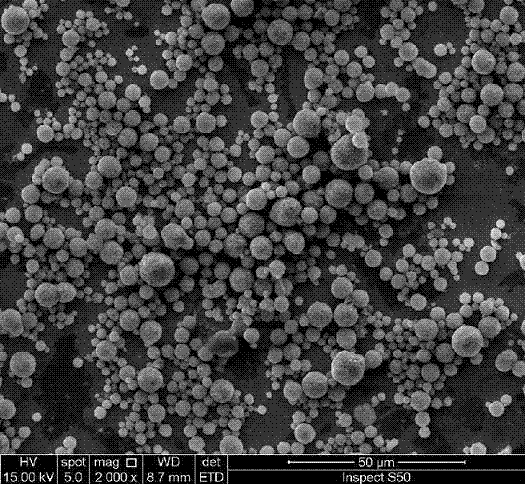

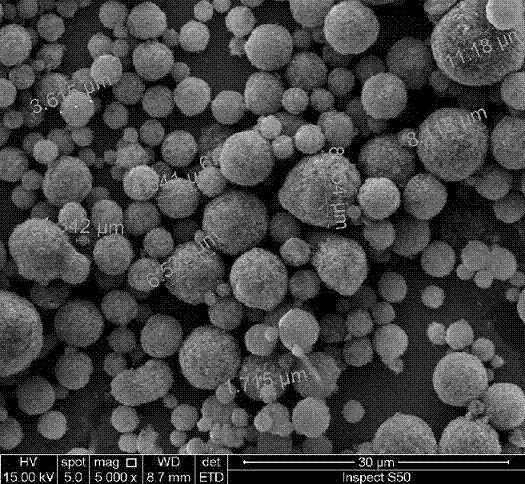

[0027] Embodiment 1: The spherical lithium titanate composite negative electrode material is prepared by the following process steps.

[0028] Add lithium carbonate, anatase titanium dioxide, hydrated magnesium trisilicate, and lithium fluoride to deionized water at a molar ratio of 0.405:1:0.002:0.002, and add 2wt% polyvinyl alcohol to form a precursor slurry with a solid content of 20wt%. Material; use a stirring ball mill to mill at a low speed of 200r / min for 2h, then at a high speed of 500r / min for 2h, until the particle D50 of the precursor slurry reaches 0.8μm, and then use an ultra-fine sand mill to sand at a low speed of 500r / min for 2h , and then sanded at a high speed of 1500 / min for 5 hours until the D50 of the precursor slurry particles reached 0.25 μm; the slurry was sent into the spray dryer at a certain feed rate (the inlet air temperature of the spray dryer was 180-220°C, The air temperature is controlled at 90-150°C) to obtain a spherical precursor, and its s...

Embodiment 2

[0032] Embodiment 2: The spherical lithium titanate composite negative electrode material is prepared by the following process steps.

[0033] Add lithium hydroxide, anatase titanium dioxide, hydrated magnesium trisilicate, and lithium fluoride to deionized water at a molar ratio of 0.800:1:0.003:0.002, and add 4wt% ammonium polyacrylate to form a precursor with a solid content of 15wt%. Slurry: Use a stirring ball mill to mill at a low speed of 300r / min for 2h, then at a high speed of 800r / min for 5h, until the particle D50 of the precursor slurry reaches 0.8μm, and then use an ultra-fine sand mill to sand at a low speed of 800r / min 2h, then sand mill at high speed 1800 / min for 2h until the D50 of the precursor slurry particles reaches 0.28μm; send the slurry into the spray dryer at a certain feed rate (the inlet air temperature of the spray dryer is 180-220°C , the air outlet temperature is controlled at 90-150°C) to obtain a spherical precursor with a secondary particle D50...

Embodiment 3

[0036] Embodiment 3: The spherical lithium titanate composite negative electrode material is prepared by the following process steps.

[0037] Add lithium nitrate, anatase titanium dioxide, hydrated magnesium trisilicate, and ammonium fluoride to deionized water at a molar ratio of 0.82:1:0.005:0.005, and add 3wt% polyvinyl alcohol to form a precursor slurry with a solid content of 15wt%. Material; use a stirring ball mill to mill at a low speed of 400r / min for 3h, then at a high speed of 900r / min for 3h, until the particle D50 of the precursor slurry reaches 0.7μm, and then use an ultra-fine sand mill to sand at a low speed of 800r / min for 2h , and then sanded at a high speed of 1900 / min for 4 hours until the D50 of the precursor slurry particles reached 0.2 μm; the slurry was fed into the spray dryer at a certain feed rate (the inlet air temperature of the spray dryer was 180-220°C, The air outlet temperature is controlled at 90-150°C) to obtain a spherical precursor with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com