Monitoring method for battery temperature

A battery temperature and battery technology, applied in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems of high cost, complicated installation and disassembly, and inability to monitor batteries, etc., and achieve the effect of convenient sticking and positive screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

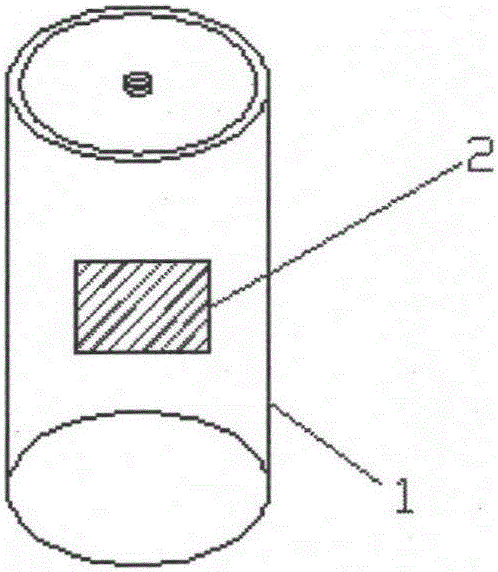

[0019] At least one temperature test paper 2 is closely attached to the cylindrical battery case 1 , and the temperature test paper 2 is closely combined with the battery case 1 . During battery storage, transportation or use, when the internal temperature of the battery changes, it is transmitted to the temperature test paper 1 through the battery case 2, so that the color of the temperature test paper 2 changes, and the battery surface temperature can be obtained quickly and in time.

Embodiment 2

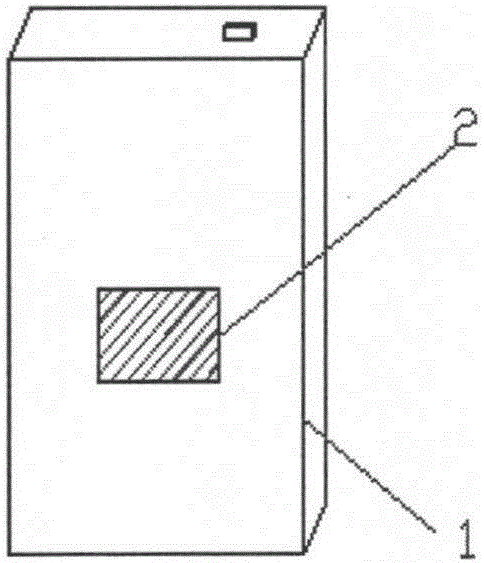

[0021] At least one temperature test paper 2 is closely attached to the square or diamond-shaped battery case 1 , and the temperature test paper 2 is closely combined with the battery case 1 . During battery storage, transportation or use, when the internal temperature of the battery changes, it is transmitted to the temperature test paper 1 through the battery case 2, so that the color of the temperature test paper 2 changes, and the battery surface temperature can be obtained quickly and in time.

Embodiment 3

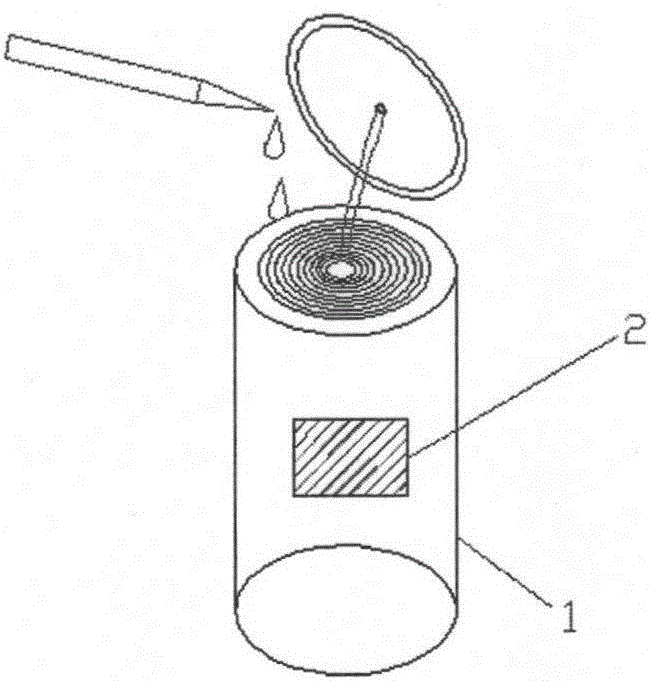

[0023] At least one temperature test paper 2 is closely attached to the battery case 1 , and the temperature test paper 2 is closely combined with the battery case 1 . During the battery filling process, when the internal temperature of the battery changes, it is transmitted to the temperature test paper 1 through the battery casing 2, so that the color of the temperature test paper 2 changes, and the battery surface temperature can be obtained quickly and in time.

[0024] The method can quickly detect the temperature state of the battery during the manufacturing process without additional equipment and installation, and can test any part according to the actual situation, select the type of temperature test paper in any combination, and perform multi-point testing, with low cost and reliable effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com