Civil scissor composite

A composite material, scissors technology, applied in the field of kitchen knives, can solve the problems of waste of resources and energy, cracking, sharpness, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

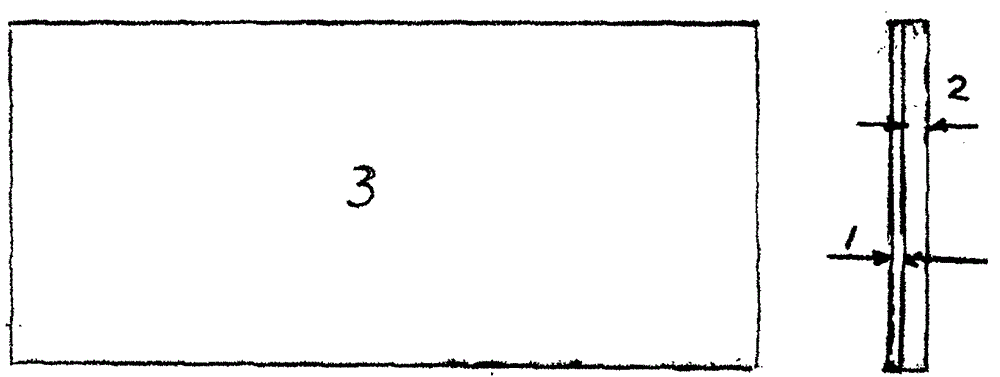

[0013] The technical scheme adopted in the present invention is: the blade is made of expensive VG-10 Wusheng special stainless steel. According to the specifications and shapes of different civilian scissors, the blade steel accounts for 15%-25% of the overall composite knife weight; the knife body material is made of low-priced high-quality martensitic 3CR13 stainless steel, accounting for 85%-75% of the overall composite knife weight; The joint surface of VG-10 Wusheng special stainless steel and 3CR13 is sealed and wrapped in 3CR13, and subjected to high temperature and high pressure of 1180-1220 degrees to achieve metallurgical compounding. The composite material is processed into civil scissors of various specifications and shapes by die or wire cutting. .

[0014] The beneficial effects of the present invention are: (1) the service life of the original 3CR13 stainless steel civil scissors can be several times; (2) by prolonging the service life, the scarce resources of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com