Cement hexavalent chromium compounded reducing agent and preparation method thereof

A hexavalent chromium and composite type technology, which is applied in the field of cement hexavalent chromium composite reducing agent and its preparation, can solve the problems of easy loss of reducibility, etc., achieve strong reducing ability, reduce costs, and improve early strength and later strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1: A cement hexavalent chromium composite reducing agent, the composition is as follows:

[0020] Sodium sulfite 15%, ferrous sulfate 70%, manganese sulfate 10%, stannous sulfate (tin (II)) 5%, the total amount is 100%; the percentages are all mass percentages.

[0021] The preparation method of cement hexavalent chromium composite reducing agent, the steps are: first disperse and mix sodium sulfite, manganese sulfate, and stannous sulfate according to the formula ratio, stir slowly in a mixer for 30 seconds to obtain the mixture; then divide the ferrous sulfate into more Add to the mixture in one time: first add 20% ferrous sulfate and stir slowly for 120s; then add 20% ferrous sulfate and stir slowly for 120s; after the addition is complete, stir slowly for more than 5 minutes until the mixture is uniform; After the impurities are filtered through the mesh stainless steel sieve, product 1 is obtained.

Example

[0022] Example 2 to Example 5:

[0023] Repeat the method of Experimental Example 1 according to the content of each component specified in Table 1 below to obtain cement hexavalent chromium composite reducing agent products 2 to 5 with different component content:

[0024] Table 1

[0025] Composition (%) Example 1 Example 2 Example 3 Example 4 Example 5 Sulfite1517182015 Ferrous sulfate7065616068 Manganese sulfate1012201510 Stannous sulfate561510 get Product 1 Product 2 Product 3 Product 4 Product 5

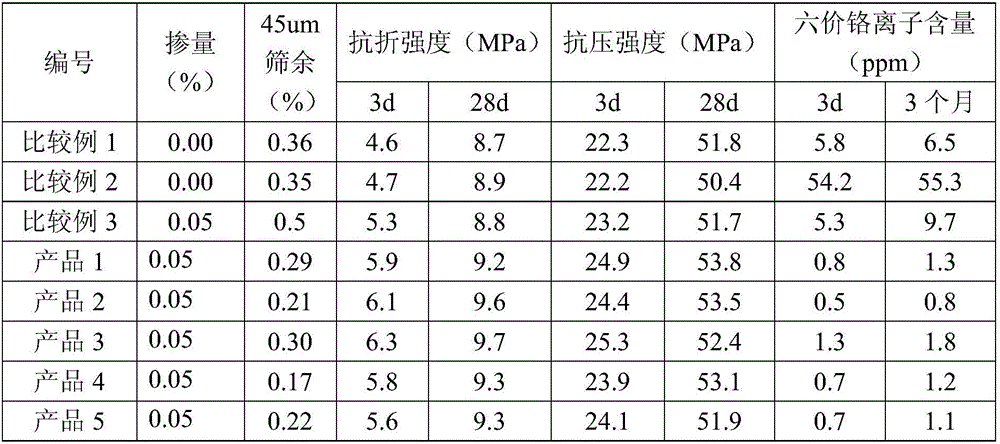

[0026] The hexavalent chromium composite reducing agent product 1 to product 5 obtained in the examples were tested separately in a Φ500×500 standard test mill. The specific process is as follows:

[0027] Mix according to the following material ratio: 63% by mass clinker, 8% by mass, 18% by mass slag, 11% by mass fly ash, and then 0.005% trioxide Chromium to obtain a mixture material.

[0028] The hexavalent chromium composite reducing agent product obtained in the embodiment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap