Splicing type building block member

A building block component and splicing technology, applied in entertainment, toys, etc., to avoid shrinkage problems, avoid shrinkage phenomenon, and reduce the thickness of the glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

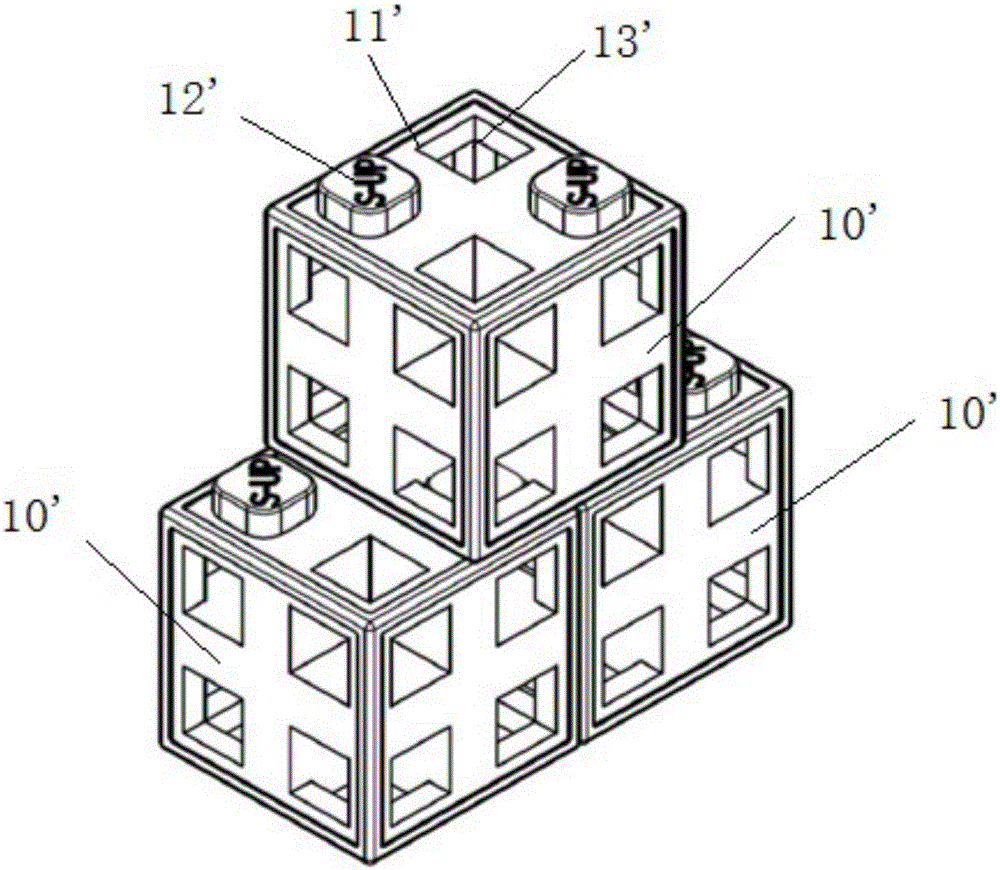

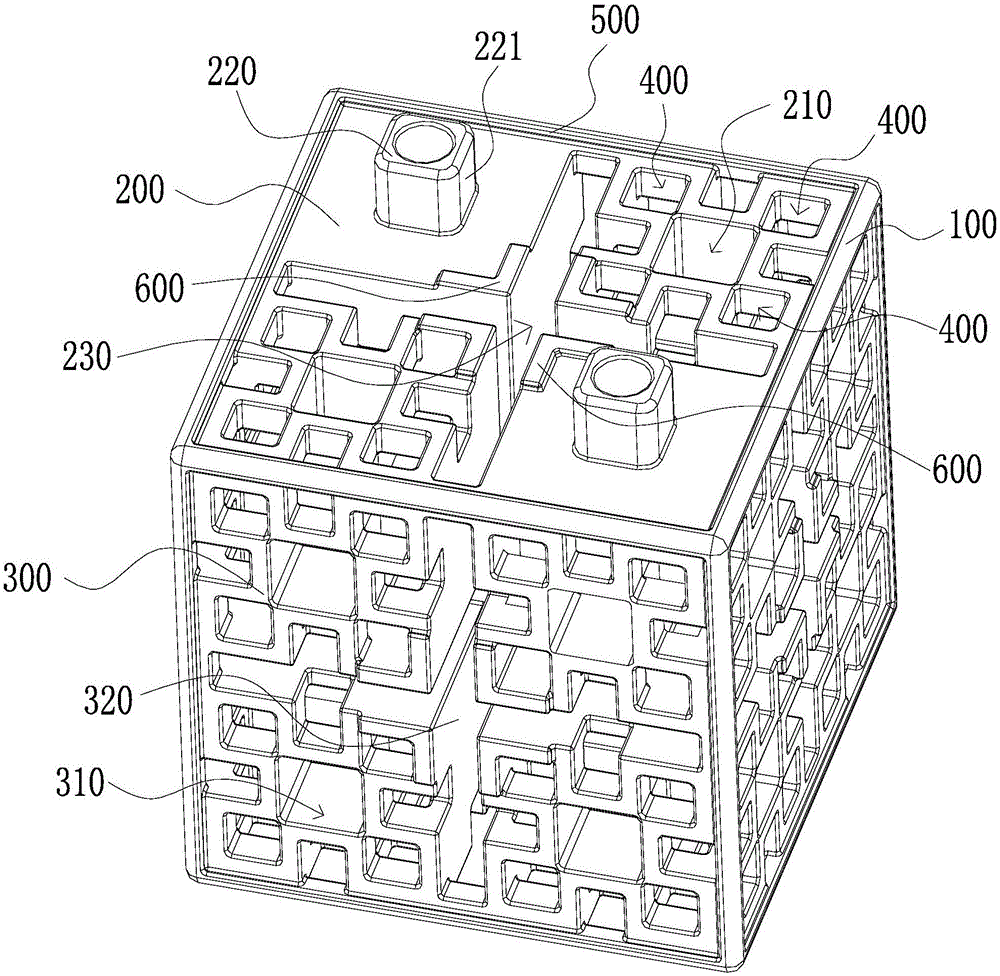

[0059] A spliced building block component, such as figure 2 As shown, the whole is a square body with a frame 100 and multiple connecting surfaces, one of which is defined as the first connecting surface 200 , and the remaining connecting surfaces are defined as the second connecting surface 300 .

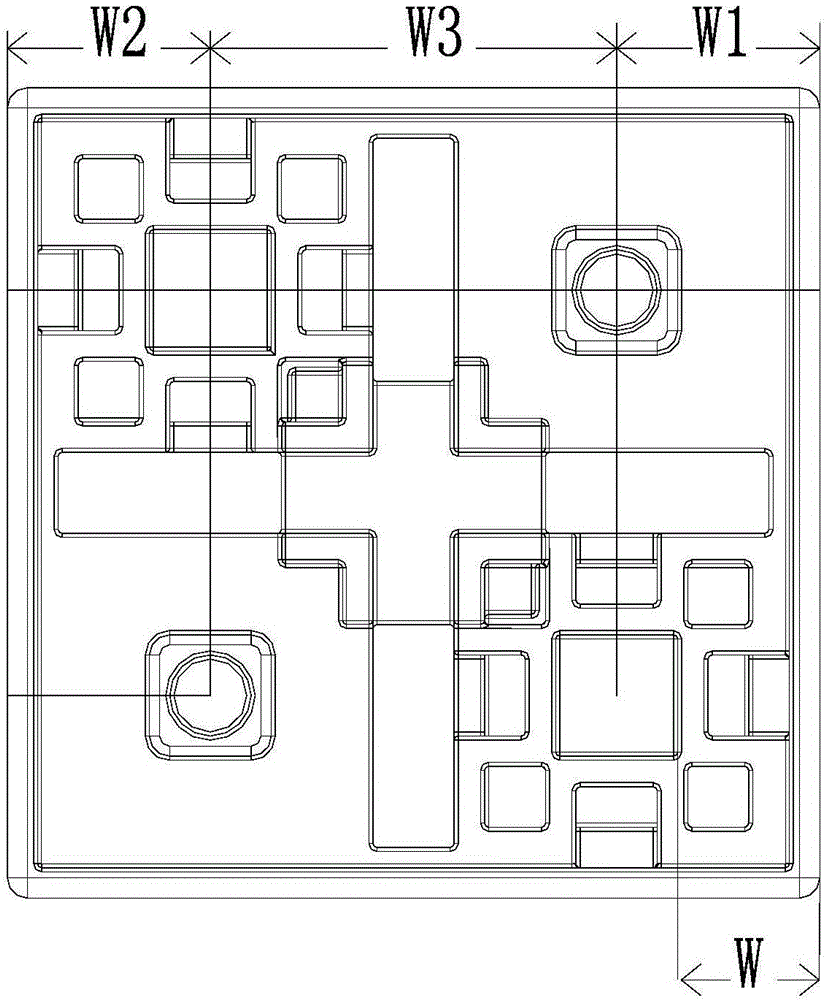

[0060] The first connection surface 200 is provided with two first large grooves 210 and two protrusions 220, and the two protrusions 220 and the two first large grooves 210 can be matched correspondingly, so The second connection surface 300 is provided with four second large grooves 310 that can fit the protrusions, and the two protrusions 220 are distributed on a pair of corners of the first connection surface 200 On the line, the two first large grooves 210 are distributed on the other diagonal on the first connection surface 200, and the four second large grooves 310 are on the second connection surface where they are located. 300 are distributed diagonally in pairs.

[0...

Embodiment 2

[0077] The spliced building block member of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0078] Such as Figure 16 As shown, a set of small groove groups is provided around each of the protrusions of the spliced building block member, and four of the small groove groups in the small groove group are uniformly arranged around the protrusion.

[0079] Through the above settings, when the spliced building block components are used in conjunction with smaller building block components, various forms of bridging can still be achieved, such as Figure 17-21 shown.

Embodiment 3

[0081] The spliced building block member of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0082] Such as Figure 22 As shown, the protrusion 220 is divided into a connection part 221 and an extension part 222 from the base to the top, the connection part can be tightly fitted with the first large groove or the second large groove, and the connection part The height is not greater than the width of the frame part formed from the edge of the first connecting surface to the first large groove, and the outer surface of the extension part extended from the connecting part is the adjoining surface, and the adjoining surface and the The angle between the first connection surfaces is ≤45 degrees.

[0083] Through the above-mentioned control, a flexible and changeable bridging method can be realized. For example, when two or three grooves adjacent to a certain vertex are inserted into two or three protrusions at the same time, a tight fit can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com