A control method of a mechanical arm type solid phase extraction apparatus

A control method and technology of robotic arms, which are applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve problems such as cross-infection, and achieve the effect of avoiding cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

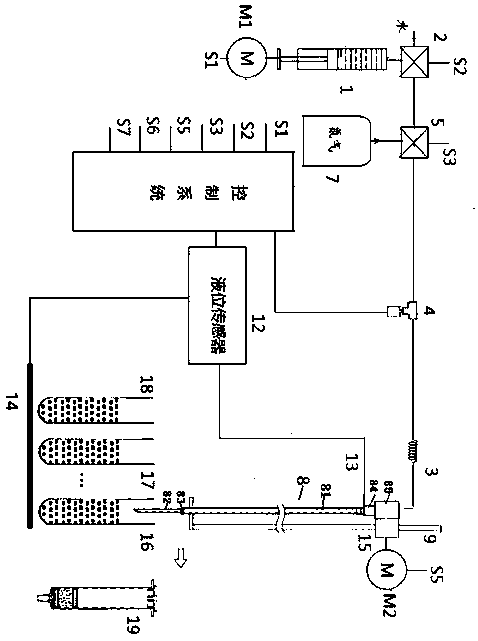

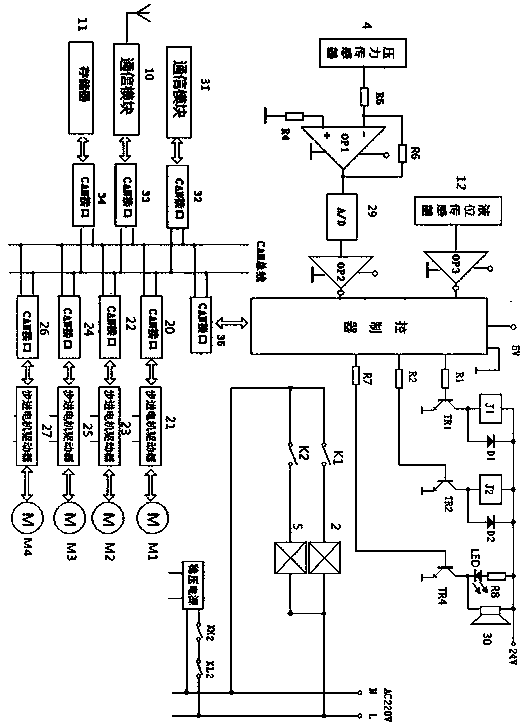

[0023] figure 1 It is a schematic diagram of the composition of the mechanical arm type solid phase extraction instrument provided by the first embodiment of the present invention, as figure 1 As shown, the mechanical arm type solid phase extraction instrument provided by the present invention can automatically track the liquid level in the container to be extracted, and can avoid cross-infection when different solutions are extracted from different containers and injected into the SPE column. The mechanical arm type solid phase extraction instrument includes a three-axis mechanical arm, and the three-axis mechanical arm includes an X arm (X axis), a Y arm (Y axis), and a Z arm (Z axis) perpendicular to each other (not shown in the figure) , the Z arm is an arm perpendicular to the ground, which can move forward and backward along the Y arm driven by the motor M3; the Y arm can move left and right along the X arm driven by the motor M4. A screw 9 is arranged on the Z arm alon...

no. 2 example

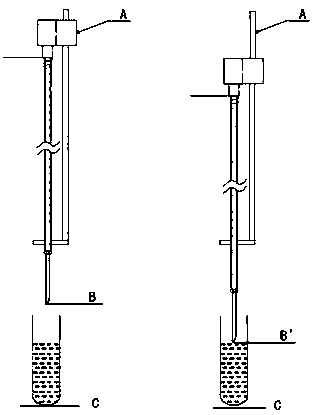

[0062] Image 6 The schematic diagram of the composition of the mechanical arm type solid phase extraction instrument provided by the second embodiment of the present invention, as Image 6 Shown, the manipulator type solid phase extractor provided by the second embodiment of the present invention is different from the first embodiment only in that the third electromagnetic reversing valve is set between the second electromagnetic valve and the liquid storage pipe 3, other The composition is the same, and only the different parts of the second embodiment and the first embodiment will be described, and the same parts will not be repeated.

[0063] The pipeline between the injection needle 8 and the injection pump 1 is also provided with a third electromagnetic reversing valve 5, wherein the first port of the first electromagnetic reversing valve 2 is connected to the injection pump, and the second port is connected to the water tank or For the alcohol tank, the third port is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com