Color steel plate rolling forming machine

A technology for forming machines and color steel plates, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large floor space, many equipment mechanisms, and high equipment prices, reducing equipment floor space and assembly requirements. , The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

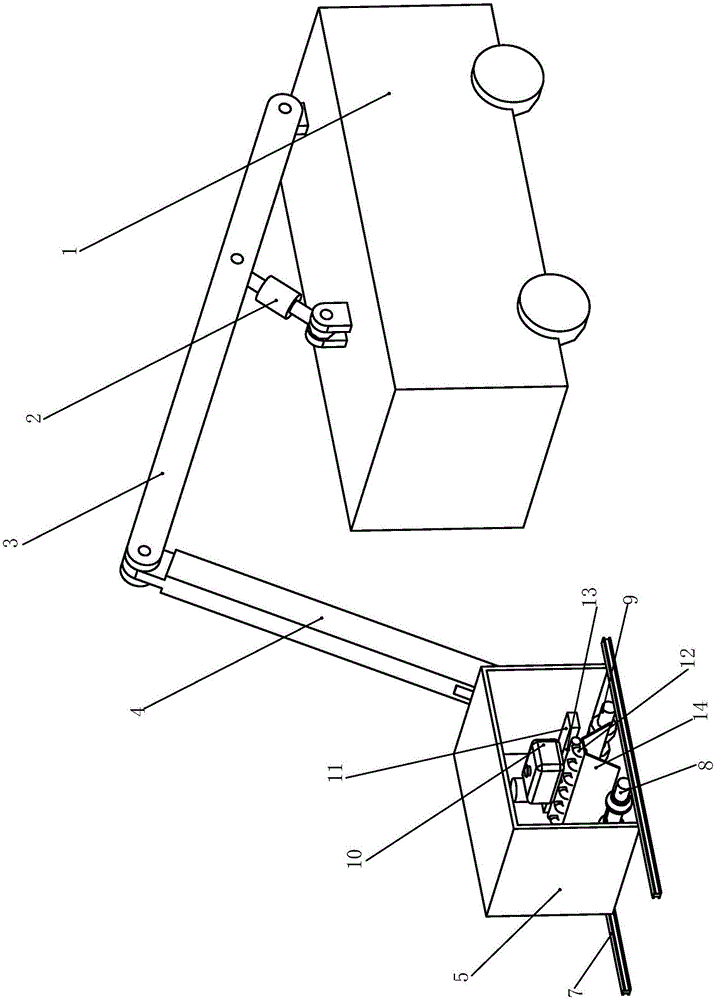

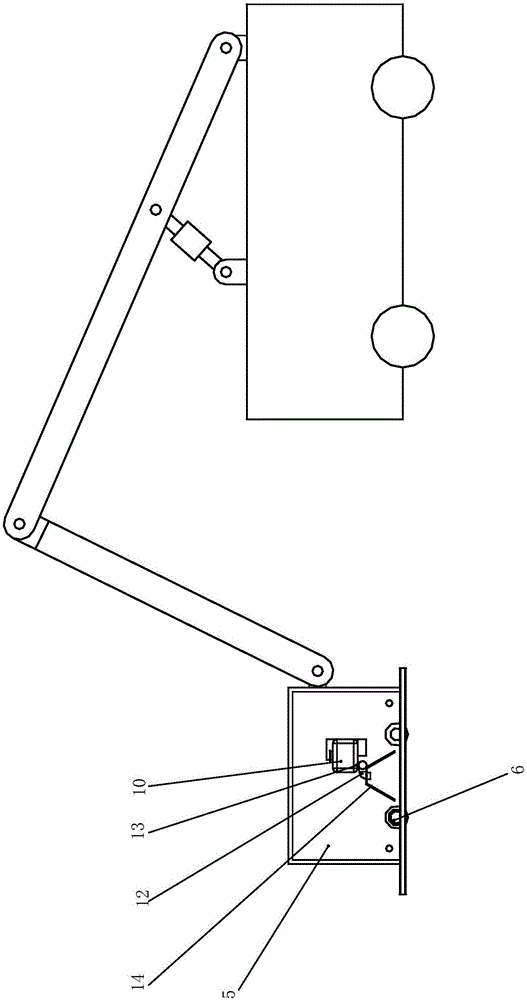

[0015] Such as figure 1 As shown, a color steel plate roll forming machine includes a mobile car 1, a hydraulic cylinder 2 is mounted on the left side of the mobile car 1 by articulation, and a boom is mounted on the right side of the mobile car 1 by articulation 3. The push rod 4 of the mobile cart 1 is hinged to the middle of the boom 3, and the other end of the boom 3 is hinged with a push rod 4; the other end of the push rod 4 is movably connected with a cart 5, which Sliders 6 are provided on the front and rear sides of the lower end of 5, and the slides 7 are fitted with slides 7 under the cart 5, and the slides 7 are inverted T-shaped slides. A pre-compression shaft 8 is movably installed on the left side, and a final pressure shaft 9 is installed on the inner right side of the cart 5 lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap