Fully automatic powder metallurgy non-metal filtering device and filtering method thereof

A powder metallurgy and filtering device technology, applied in the field of ultrasonic cleaning, can solve the problem that non-metallic particles cannot be cleaned, and achieve the effect of strong cleaning effect and improved workpiece quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

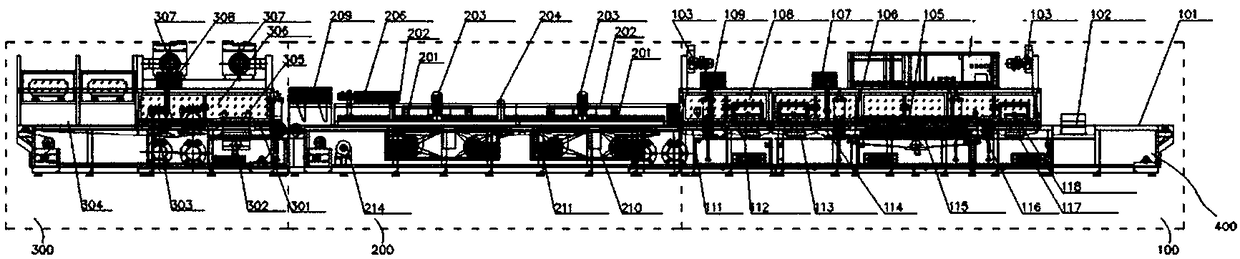

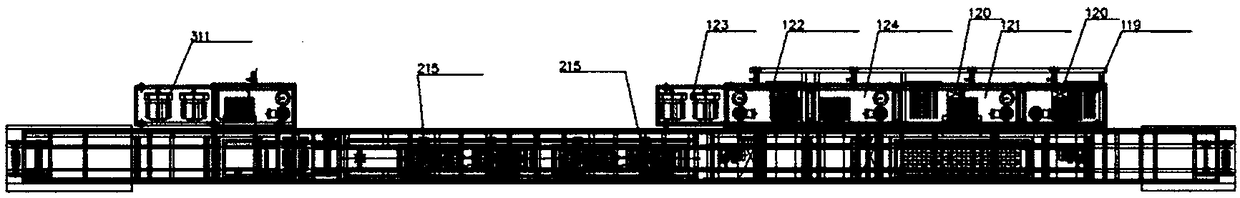

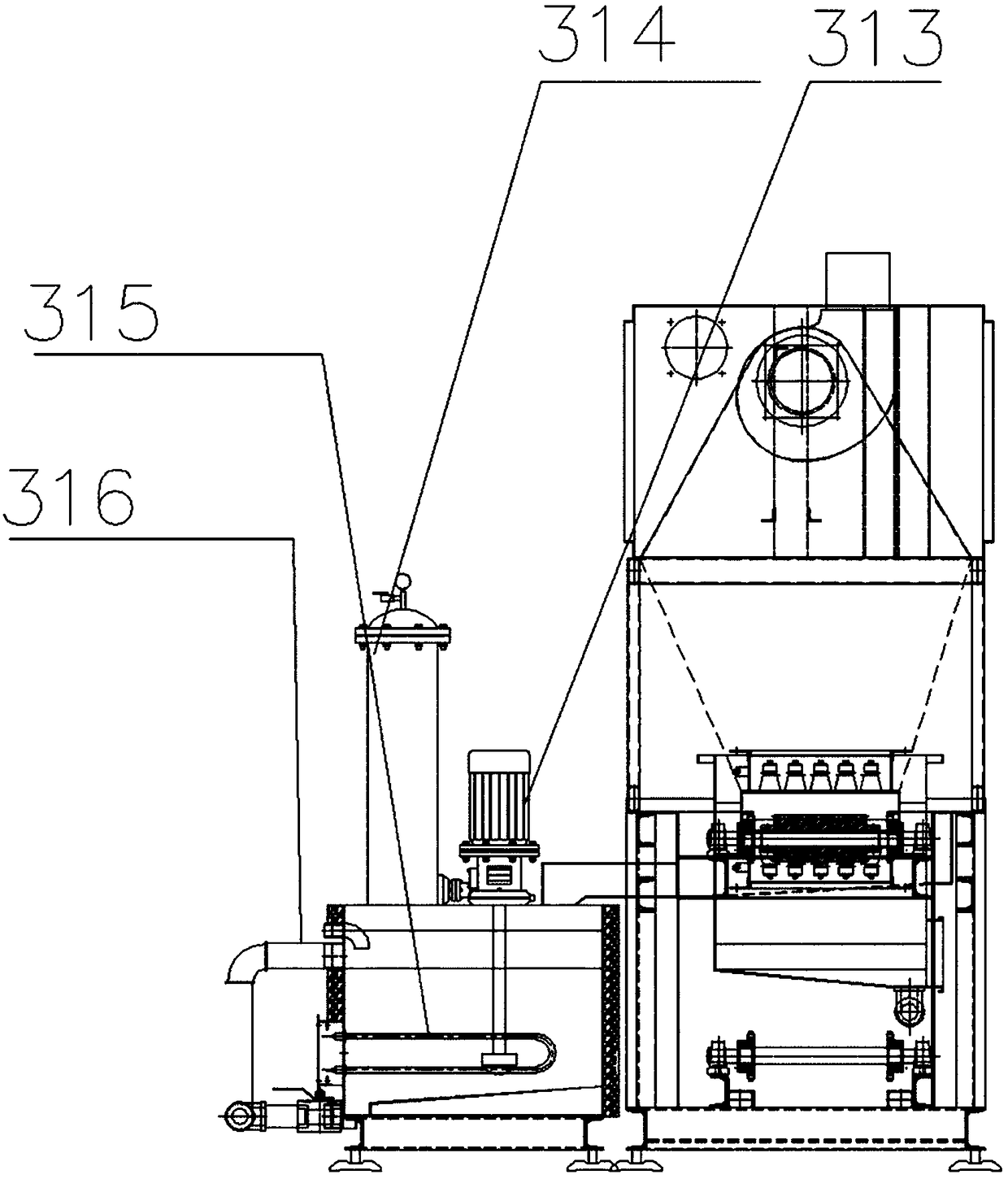

[0023] As shown in the figure, the fully automatic powder metallurgy non-metallic filtration device includes a frame 400, and the frame 400 is sequentially installed with a super rinsing device 100, a drying device 200 and a soaking device 300; the super rinsing device 100, the drying device 300 Both the drying device 200 and the soaking anti-rust device 300 are connected to the electrical control cabinet with a power transmission line group. The super rinsing device 100 includes a feeding table 101, and the discharge end of the feeding table 101 is sequentially installed with a coil demagnetizer 102, a spray washing tank 117, an overflow tank 116, an ultrasonic cleaning tank 115, a cleaning water knife 106, a blower The liquid tank 114, the spraying and rinsing tank 113, the soaking and rinsing tank 112 and the drying tank 111, wherein: the spraying and washing tank 117 is connected with a spray pipe 118, and the ultrasonic cleaning tank 115 is installed with a super-vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com