Pneumatic variable stiffness flexible mirror milling support head for real-time thickness measurement

A technology of mirror milling and variable stiffness, used in supports, measuring/indicating equipment, clamping, etc., can solve the problem of inability to actively adjust the stiffness of the support head, and achieve the effect of reducing control difficulty, increasing effective area, and suppressing chattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention but not to limit the present invention.

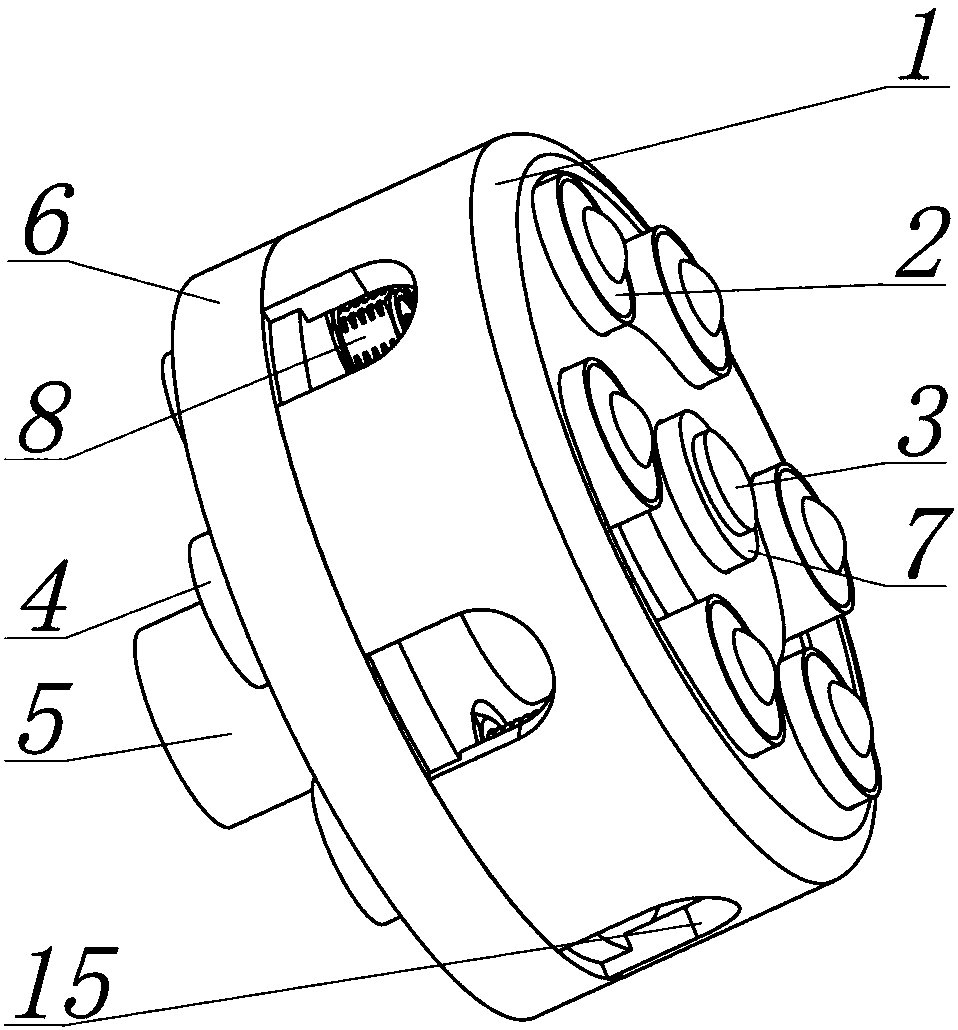

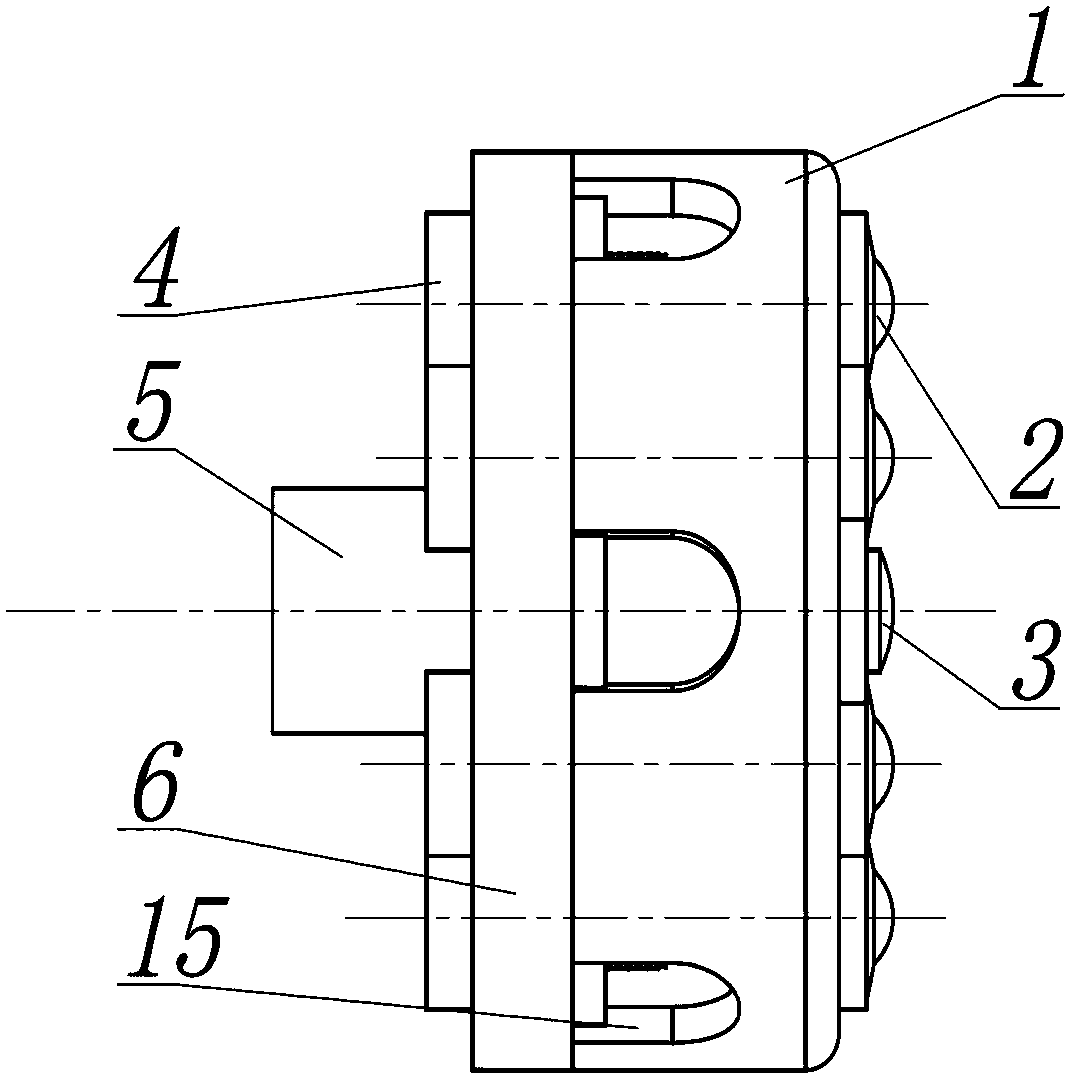

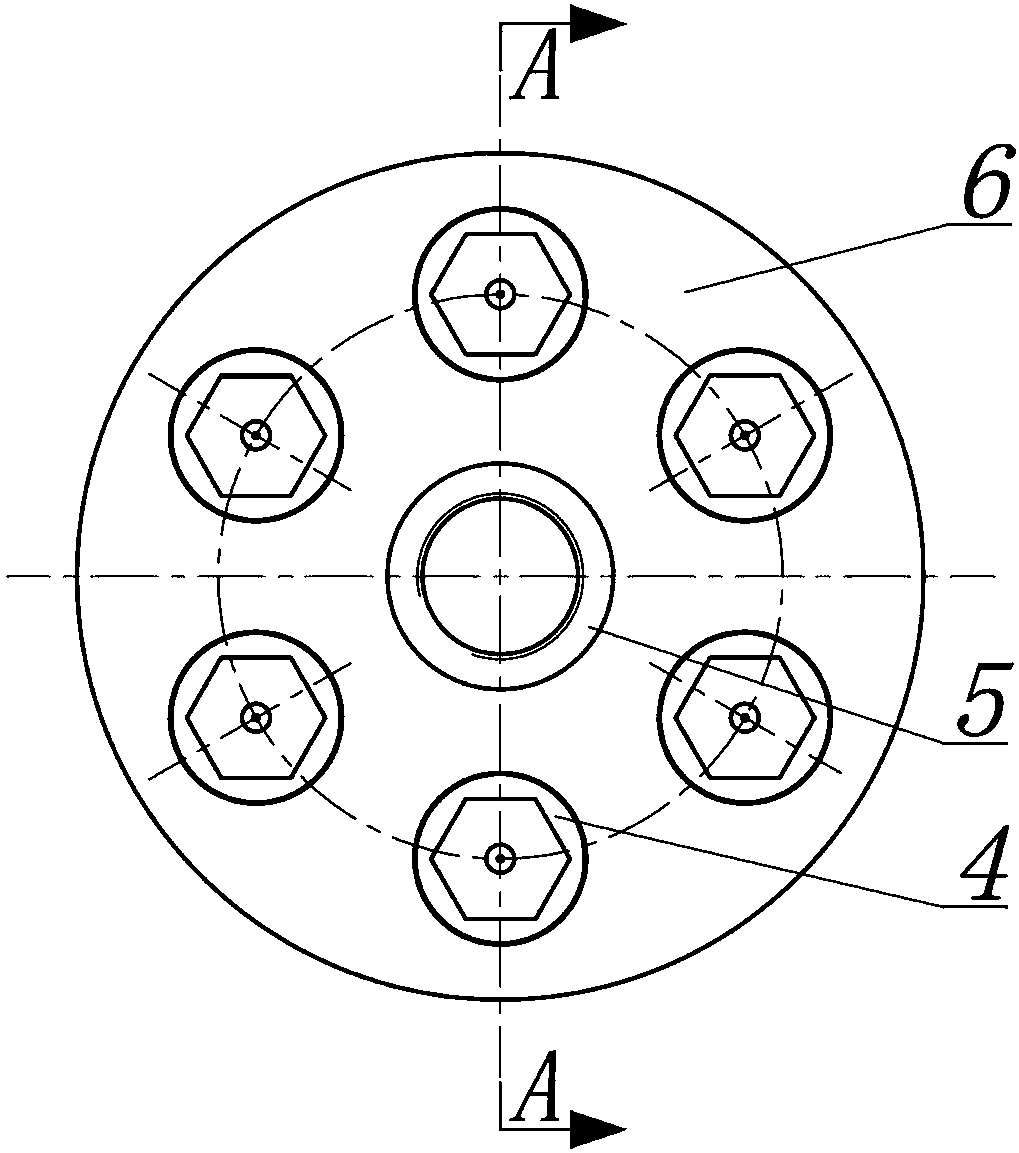

[0018] As shown in the accompanying drawings, the pneumatic variable rigidity flexible mirror milling support head for real-time thickness measurement of the present invention includes a base 6, a base 1 is fixed on the base 6, and a base 1 is opened at the middle position of the base 1. There is a central through hole, and a plurality of circular arc through holes 14 with axes parallel to the axis of the central through hole are evenly opened around the central through hole along the same circumferential direction. The positions of the base 6 corresponding to the two arc ends and the central through hole are respectively provided with a circumferential mounting threaded through hole 12 and a central stepped threaded hole, and a prob...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap