Method for resource utilization of waste acid with arsenic and fluorine import

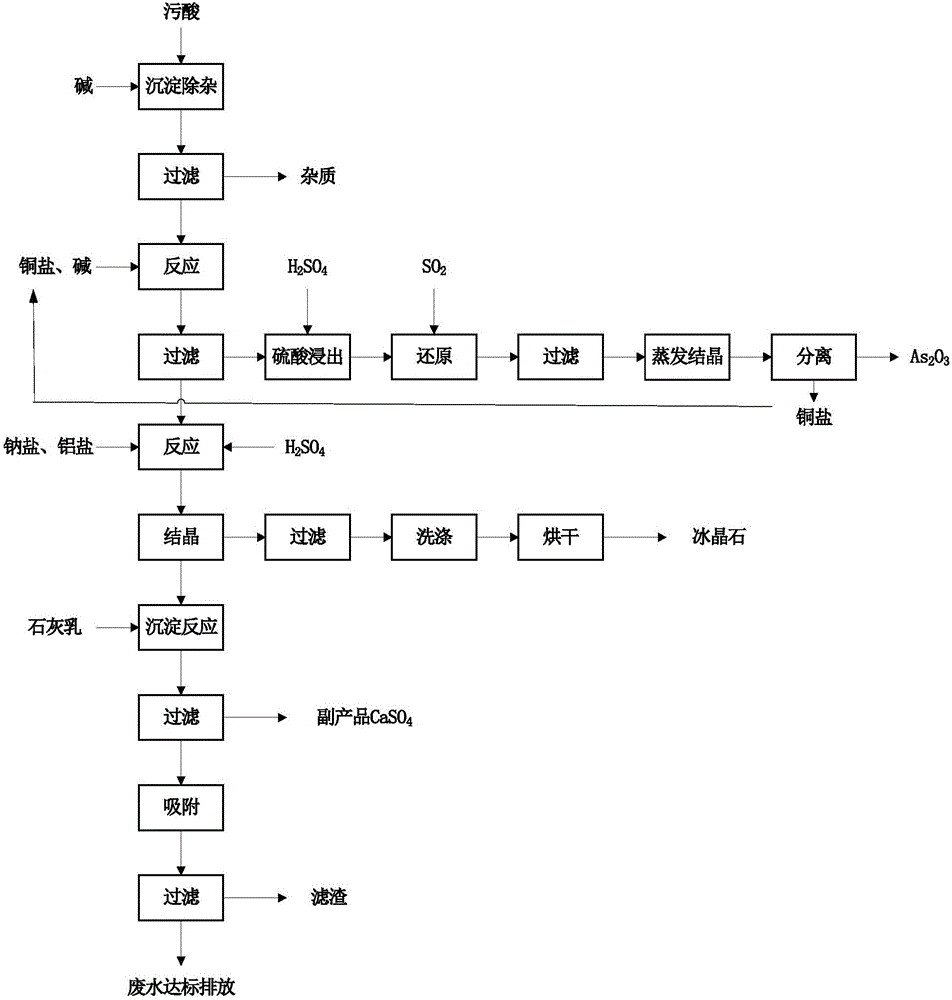

A technology for recycling and polluting acid, applied in chemical instruments and methods, aluminum fluoride, arsenic compounds, etc., can solve the problems of increased environmental pollution load, a large amount of waste sludge, no utilization, etc., and achieves fewer reaction steps and simple process. , easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take a certain amount of dirty acid containing arsenic and fluorine, add solid sodium hydroxide to precipitate and remove impurities, the amount of solid sodium hydroxide added is based on adjusting the pH value of the dirty acid to 6, and stir at room temperature for 30 minutes. Filter and keep the filtrate.

[0043] Add solid copper sulfate to the filtrate in such an amount that the molar ratio of Cu and As is 1.5:1. While stirring, a sodium hydroxide solution with a mass fraction of 25% was added dropwise, the pH was controlled to be 8, and the reaction was stirred at 40° C. for 30 minutes. Filter to obtain filter cake A and filtrate A. Filter cake A is leached with dilute sulfuric acid with a mass fraction of 15%, the liquid-solid ratio (mL / g) is 4:1 during leaching, the leaching reaction is 45min, and SO is passed into the leaching solution 2 Gas, reduced reaction at room temperature for 45 minutes, filtered, and retained filtrate B. After the filtrate B was eva...

Embodiment 2

[0047]Take a certain amount of dirty acid containing arsenic and fluorine, add solid sodium hydroxide to precipitate and remove impurities, the amount of solid sodium hydroxide added is based on adjusting the pH value of the dirty acid to 6, and stir at room temperature for 20 minutes. Filter and keep the filtrate.

[0048] Add solid copper sulfate to the filtrate in such an amount that the molar ratio of Cu and As is 1.5:1. While stirring, a sodium hydroxide solution with a mass fraction of 25% was added dropwise to control the pH to 9, and the reaction was stirred at 50° C. for 45 minutes. Filter to obtain filter cake A and filtrate A. Filter cake A is leached with dilute sulfuric acid with a mass fraction of 15%, the liquid-solid ratio (mL / g) during leaching is 5:1, the leaching reaction is 60min, and SO is passed into the leaching solution 2 Gas, reduction reaction at room temperature for 60min, filter, and keep the filtrate B. After the filtrate B was evaporated and cr...

Embodiment 3

[0052] Take a certain amount of dirty acid containing arsenic and fluorine, add solid sodium hydroxide to precipitate and remove impurities, the amount of solid sodium hydroxide added is based on adjusting the pH value of the dirty acid to 6, and stir at room temperature for 30 minutes. Filter and keep the filtrate.

[0053] Add solid copper sulfate to the filtrate in such an amount that the molar ratio of Cu and As is 1.5:1. While stirring, sodium hydroxide solution with a mass fraction of 25% was added dropwise, the pH was controlled to be 8, and the reaction was stirred at 60° C. for 60 min. Filter to obtain filter cake A and filtrate A. The filter cake A is leached with dilute sulfuric acid with a mass fraction of 15%, the liquid-solid ratio (mL / g) is 6:1 during leaching, the leaching reaction is 60min, and SO is passed into the leaching solution 2 Gas, reduction reaction at room temperature for 60min, filter, and keep the filtrate B. After the filtrate B was evaporated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com