Paint spraying device used for lacquerware manufacturing

A control device and lacquerware technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of limited painting area and speed of paint brush, slow manual painting speed, etc., and achieve rich functions, good spraying effect and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] Example 1

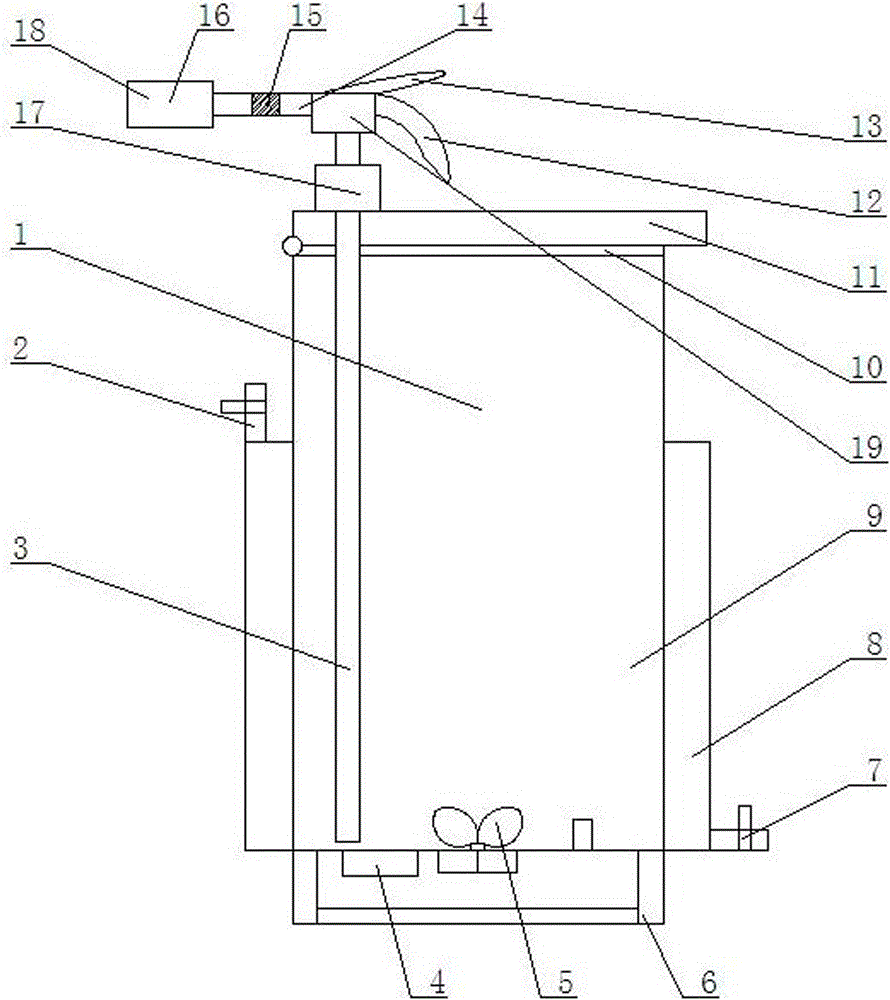

[0015] Such as figure 1 As shown, a paint spraying device for making lacquerware includes a cylinder body 1, a support base, and the bottom end of the cylinder body 1 is mounted on a support base 6; the cylinder body 1 is composed of a cylinder body 9, a cylinder cover 11, and a bucket cover The lower left end is connected to the upper left end of the cylinder body 9 through an overturning connector; the lower side of the outer end of the cylinder body 9 is equipped with a surrounding greenhouse 8; the top left of the surrounding greenhouse 8 is equipped with a tempered water inlet pipe 2, and the lower right end is equipped with tempered water Drain pipe 7; the inner bottom of the barrel 9 is equipped with a vortex stirrer 5 at the bottom right of the temperature detector; the barrel 1 is equipped with a paint pipe 3, and the top of the barrel 1 is equipped with a miniature paint draw Pump 17, the lower end of the mini paint pumping pump 17 is connected to th...

Example Embodiment

[0016] Example 2

[0017] Such as figure 1 As shown, the bottom end of the cylinder 1 is equipped with an electric heating device 4.

Example Embodiment

[0018] Example 3

[0019] Such as figure 1 As shown, the paint spraying control device 18 is composed of a transfer cylinder 19, a control press sheet 13, a paint spraying pipe, a connecting pipe 15, a paint spraying head 16, and a handle 12; the bottom end of the transfer cylinder 19 is connected to a micro paint pumping tube through a paint supply pipe The pump 17, the upper end of the intermediate drum 19 is equipped with a control tablet 13, the right end of the intermediate drum 19 is equipped with a handle 12, the left end of the intermediate drum 19 is connected to a paint spraying pipe; the left end of the paint spraying pipe is connected to a paint spraying head 16 through a connecting pipe 15.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap